FEP is a kind of chemical substance, whose full name is fluorinated ethylene propylene copolymer. FEP is copolymerized with tetrafluoroethylene and hexafluoropropylene. The melting point of FEP is 304 ℃, and the density is 2.15g/cc (g / cm3).

FEP can be applied to soft plastics, and its tensile strength, wear resistance and creep resistance are lower than those of many engineering plastics. It is chemically inert and has a low dielectric constant (2.1) over a wide temperature and frequency range.

Performance characteristics

Crystallinity

FEP resin is a kind of crystalline polymer, and its crystallinity is lower than that of PTFE. FEP has a melting point of 580f and a density of 2.15g/cm3 (g / cm3). It is a kind of soft plastic. Its tensile strength, wear resistance and creep resistance are lower than those of many engineering plastics.

When the FEP resin is cooled slowly below the crystal melting point, the crystallinity of FEP resin is higher, between 50% and 60%; when the melt is cooled rapidly by quenching, the crystallinity of FEP resin is lower, between 40% and 50%. FEP resin is spherulite structure, and its structure will be different due to processing temperature and heat treatment method.

Chemical stability

The chemical stability of FEP resin is similar to that of polytetrafluoroethylene, and it has excellent chemical stability. In addition to reacting with fluorine, molten alkali metal and chlorine trifluoride at high temperature, it is not corroded when contacting with other chemicals.

Insulation performance

The electrical insulation property of FEP resin is very similar to that of PTFE. The dielectric coefficient remains unchanged in a wide range of temperature and frequency (- 80 ~ 200 ℃, 50 ~ 1010hz); the dielectric loss tangent changes with frequency, but it is not affected by temperature.

The volume resistivity of FEP resin is very high, generally more than 1015 Ω. M, and it changes little with temperature, and is not affected by water and moisture. The arc resistance is more than 165S.

The breakdown field strength of FEP resin increases with the decrease of thickness. When the thickness is greater than 1 mm, the breakdown field strength is above 30 kV / mm, but it does not change with the change of temperature.

Thermal stability

FEP resin has lower heat resistance than polytetrafluoroethylene and can be used continuously in the temperature range of - 80 ~ 200 ℃. It can also be used for a short time under the limit conditions of - 200 ℃ and 260 ℃.

The thermal decomposition temperature of FEP resin is higher than the melting point temperature, and significant thermal decomposition occurs above 400 ℃. However, due to the existence of a small amount of unstable end groups in FEP resin, it will decompose when the temperature is above the melting point, so proper ventilation must be paid attention to when processing above 300 ℃.

Mechanical property

Compared with polytetrafluoroethylene, FEP resin has higher hardness, tensile strength and friction coefficient. FEP has better creep resistance at room temperature, but its creep resistance is lower than that of polytetrafluoroethylene when the temperature is higher than 100 ℃.

Application

FEP resin can be divided into granular material, dispersion and powder according to processing requirements. According to the different melt index, granular materials can be divided into molding, extrusion and injection molding; dispersion liquid is used for impregnation and sintering; powder is used for electrostatic spraying and molding.

General application

FEP can be applied to soft plastics, and its tensile strength, wear resistance and creep resistance are lower than those of many engineering plastics. It has good chemical inertness, wide temperature and frequency range, and low dielectric constant. Therefore, FEP film is widely used in chemical and pharmaceutical sealing layer, capacitor medium, special cable insulation layer, wire insulation, electrical instrument insulation and sealing gasket.

5g communication

FEP is widely used in the field of information and communication due to its low polarity, low dielectric constant and low dielectric loss. In 5g communication era, FEP thin films are also widely used in FCCL insulation. In addition, because of its good performance, FEP is widely compounded with PI film and LCP film in electronic communication industry to improve the comprehensive performance of products.

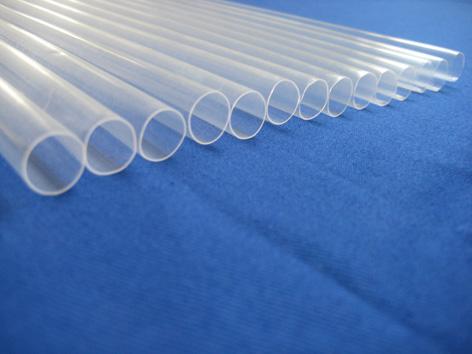

China factory FEP tube always popular to overseas market. If you have interested in our FEP tube, please contact us as soon as possible!