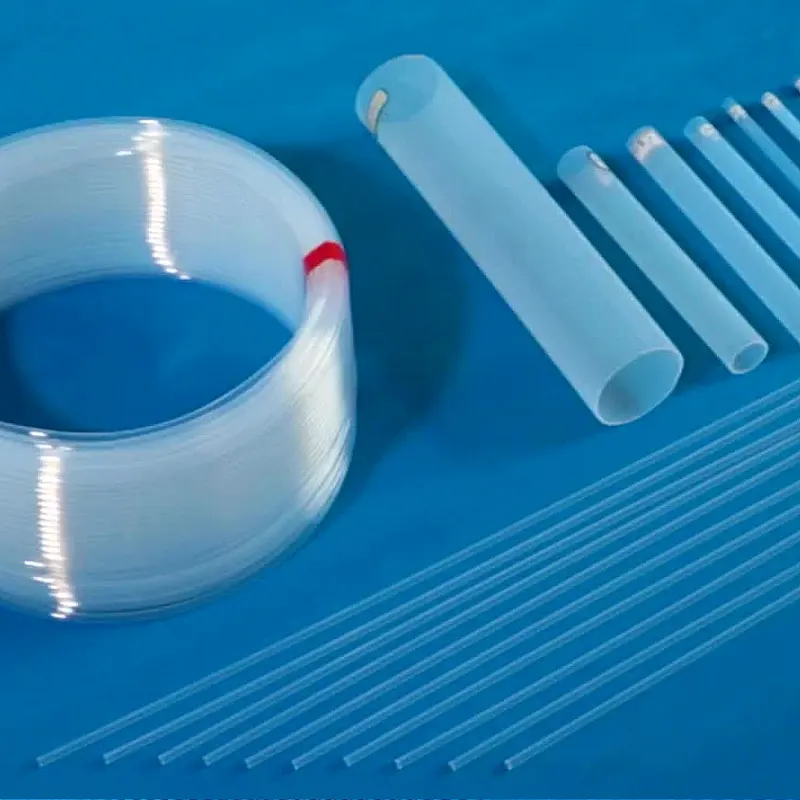

FEP & PFA Tubing

Rely on our extensive expertise in the PTFE tube industry, with over 15 years of experience delivering exceptional solutions to our valued customers. Till now, YOZONE, as reputed China FEP & PFA Tubing manufacturer and supplier, supplies quality PFA and FEP tubing.

-

FEP100% Virgin Flexible Transparent Tubing OEM Manufacturer

-

PFA 100% Virgin Transparent Extruded Tubing OEM Suppliers For Semiconductor

PFA Tubing By YOZONE-Technology

- Chemical Processing: PFA tubing is widely used in the handling and transportation of corrosive chemicals.Because PFA tubing exhibits exceptional resistance to a wide range of chemicals.

- Semiconductor Industry: PFA tubing can withstand high temperatures, typically up to 260°C (500°F). So, PFA tubing is employed in the semiconductor industry for the conveyance of ultra-pure gases and liquids.

- Pharmaceutical Industry: PFA tubing is commonly used in pharmaceutical manufacturing facilities for the handling of sterile fluids and medications.As it meets stringent cleanliness and biocompatibility standards.

- Food and Beverage Industry: PFA tubing is utilized in food and beverage processing plants for transferring liquids and gase.PFA tubing is transparent, enabling visual inspection of the fluid flow and ensuring clarity in fluid transfer processes.

- Aerospace Industry: PFA tubing is used in aerospace applications due to high-temperature resistance and chemical compatibility are crucial.

YOZONE Also Produces FEP Tubing

- Firstly, It is a copolymer of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP), combining the exceptional properties of both materials. Additionally, FEP tubing, also known as fluorinated ethylene propylene tubing, is a versatile and high-performance plastic tubing widely used in various industries.

- FEP Tubing also may applies in wide range of industries, such as food and beverage processing plants, pharmaceutical manufacturing facilities and medical devices, employed in the semiconductor industry, handling and transportation of corrosive chemicals, etc.

As leading factory of PEP tubes, with experience seamless and professional communication with our team of senior technical engineers, available 24/7 to address your queries and concerns, then we may present you professinal information below:

FEP Tubing VS. PE (Polyethylene)

- FEP tubing exhibits superior chemical resistance compared to PE. While, PE, on the other hand, has limited chemical resistance and may degrade when exposed to certain chemicals.

- FEP tubing can withstand higher temperatures than PE. While, PE typically has a maximum service temperature of around 80°C (176°F).

- FEP tubing is transparent. However, PE is also transparent, but it may not provide the same level of clarity as FEP tubing.

Why FEP Tubing Better Than PET (Polyethylene Terephthalate)

PET, while resistant to many chemicals, may degrade when exposed to certain solvents and aggressive chemicals.

PET typically has a maximum service temperature of around 150°C (302°F).

FEP tubing has a lower gas permeability rate compared to PET.

FEP tubing is more flexible than PET, especially at low temperatures.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn