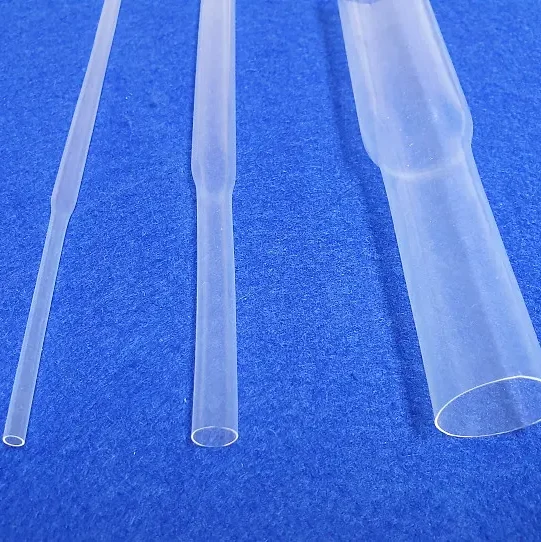

Heat Shrink Tubing

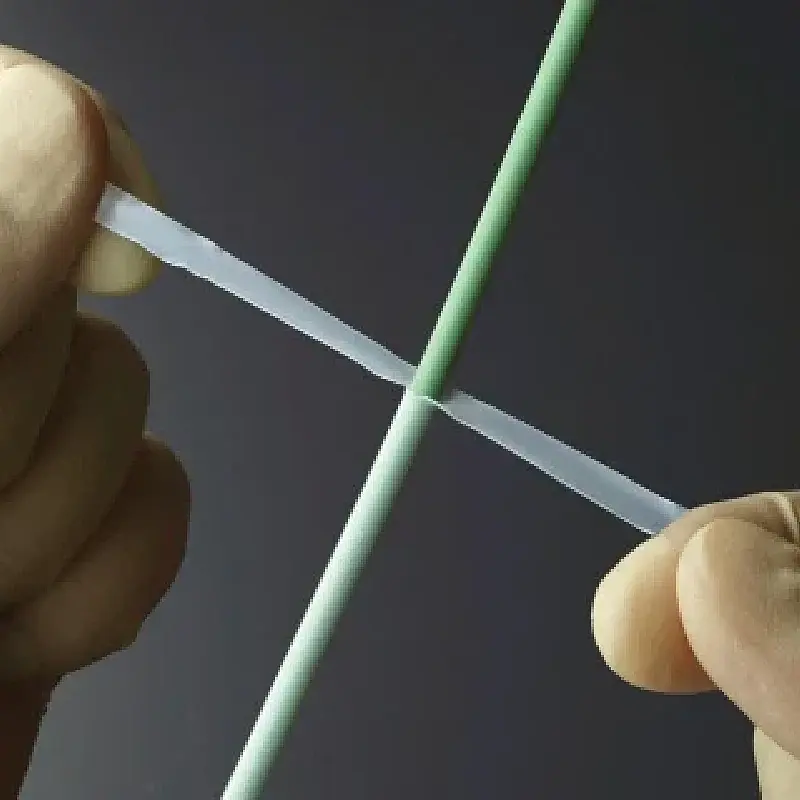

YOZONE, as leading manufacturer and supplier of Heat Shrink Tubing production, always provides quality Heat Shrink Tubings as well. Heat shrink tubing is typically made of a polymer material, such as polyolefin, that shrinks in diameter when heated, conforming tightly around the object it is applied to.

-

ETFE Customized Heat Shrink Tubing OEM Manufacturer

-

Polyolefin (PO) Fire Retardant Insulation Heat Shrinking Tubing Sleeves

-

Viton Heat Shrink Tubing OEM Manufacturer

-

PVDF Heat Shrink Tube OEM Manufacturer

-

FEP Peelable Heat Shrink Medical Grade Tube with Bio-Compatibility Certification

-

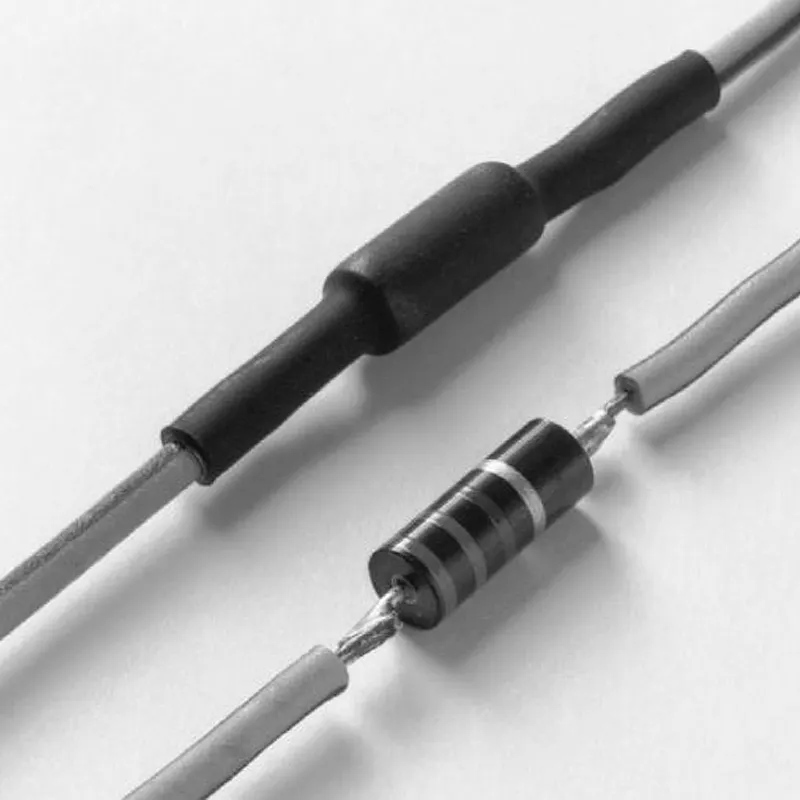

PTFE/FEP Dual Wall Heat Shrink Tubing Customized OEM Manufacturer

-

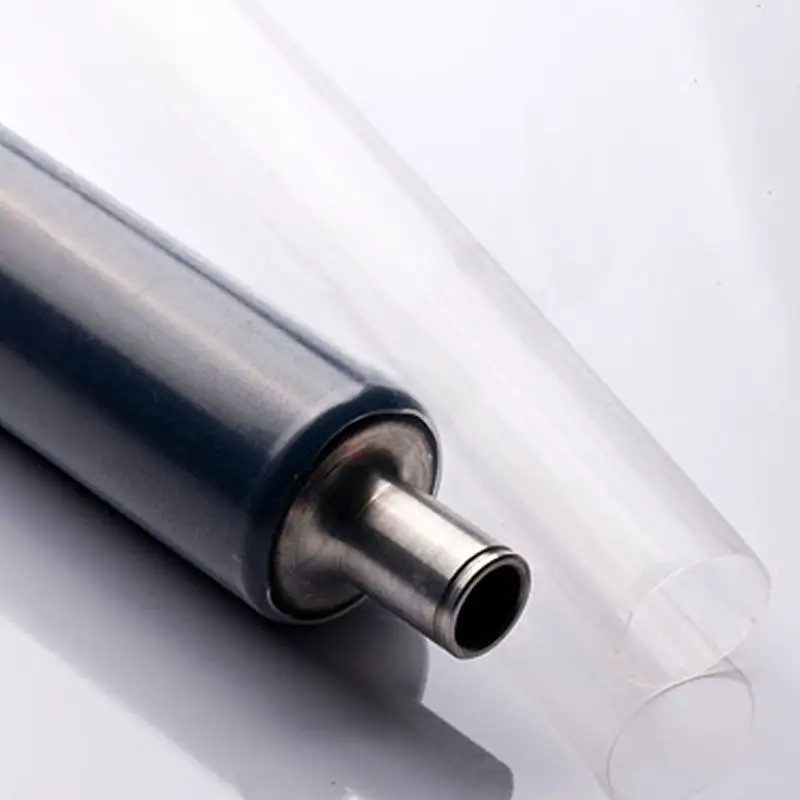

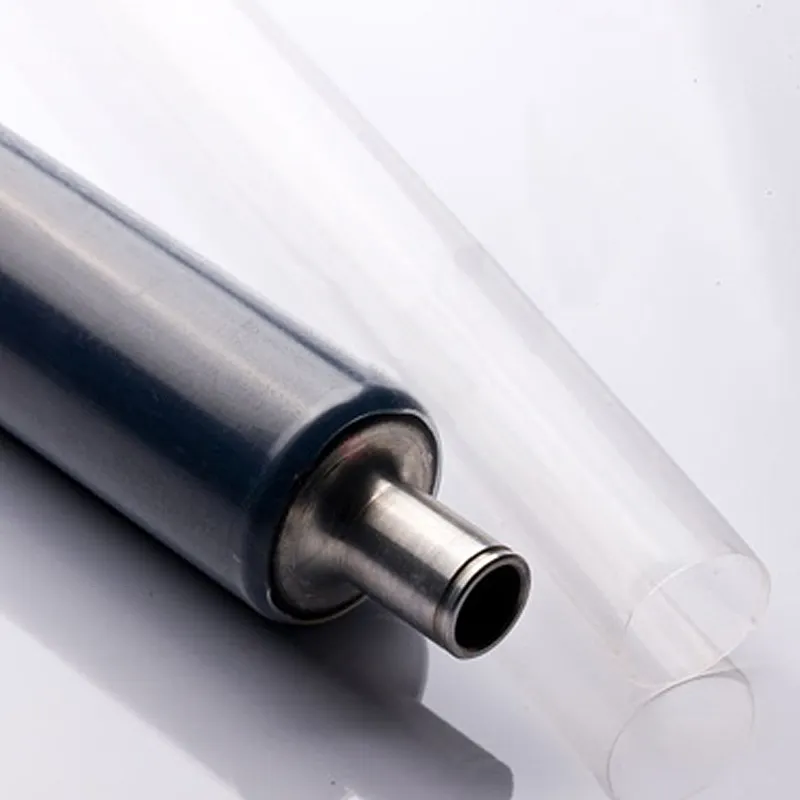

Customized PTFE Heat Shrink Tube Thin Wall Insulation Sleeve for Medical Catheter 4:1, 2:1 Ratio

-

FEP Insulation Anti-Uv 1.6:1 1.3:1 Heat Shrink Diameter 1-150mm Tubing Sleeves

-

PFA Heat Shrink Tubing Sleeves for Semi-conductor Anti-UV and High Temperature Resistance

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn