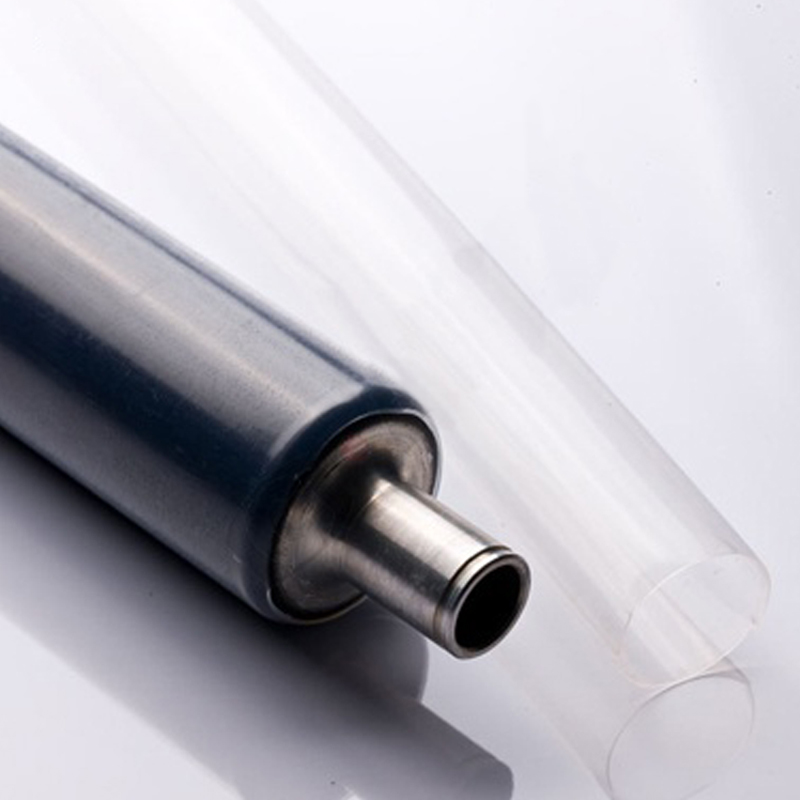

YOZONETECH must choose the correct pipe material to produce shrink tube, otherwise it will not only fail to achieve the expected effect, but also may prematurely age and fail. What I recommend here is the China factory FEP tube, which is a two-layer tube made of fluoroplastics and has excellent performance in all aspects.

If it is a shrink tube of general material, it will inevitably appear yellowing after using it for a period of time, resulting in a decrease in the light transmittance of the tube. But if FEP tube is used as shrink tube, the result is completely different.

Tests have found that FEP tube has good weather resistance and strong resistance to ultraviolet rays, so even if it is used for a long time, FEP tube will not appear aging, deterioration, yellowing and other adverse phenomena.

The wall thickness of the FEP pipe is very uniform, and the difference in fracture strength is generally small, so even if it is broken, it will not splash, and the safety is greatly improved.

However, this kind of fluoroplastic raw material product has a characteristic, it must undergo secondary processing to obtain the desired product. In fact, FEP pipe is processed in this way, and the secondary processing technology is expanded.

Due to the processing characteristics of fluoroplastics, some products are difficult to form at one time and need to go through the corresponding secondary processing technology. In addition to the blowing process, the production of FEP pipes also includes cutting, welding, lining and many other technologies.

The cut here is similar to the metal cutting method, but it is important to note that the blank must be placed for 24 hours before cutting, welding in special clamps, and a certain amount of pressure must be applied to the lining, which is mainly black, which mainly exerts the effect of corrosion resistance.