Extruded tubing from China Extruded Tubing factory, plays a crucial role in various industrial sectors, offering valuable solutions that cater to specific needs. Whether you require the strength and versatility of aluminum extruded tubing, the flexibility of silicone tubing, or the customizability of plastic tubing, each type offers unique benefits and applications. Consider the specific demands of your industry and explore the possibilities of extruded tubing to enhance efficiency, durability, and performance.

Aluminum extruded tubing offers a winning combination of strength, durability, and versatility, making it a popular choice in various industrial applications. Here are some key aspects of aluminum extruded tubing:

Strength and lightweight: Aluminum is known for its exceptional strength-to-weight ratio, making extruded aluminum tubing an excellent choice for applications that require structural integrity without adding unnecessary weight.

Customizable shapes and sizes: Extrusion processes allow for the creation of aluminum tubing in various shapes, including rectangular profiles. This versatility ensures that the tubing can be tailored to fit specific industrial requirements.

Corrosion resistance: Aluminum naturally forms a protective oxide layer, providing excellent resistance to corrosion and ensuring longevity in challenging environments.

Wide range of applications: Aluminum extruded tubing finds applications in industries such as construction, automotive, aerospace, and marine, where its strength, lightweight nature, and corrosion resistance are highly valued.

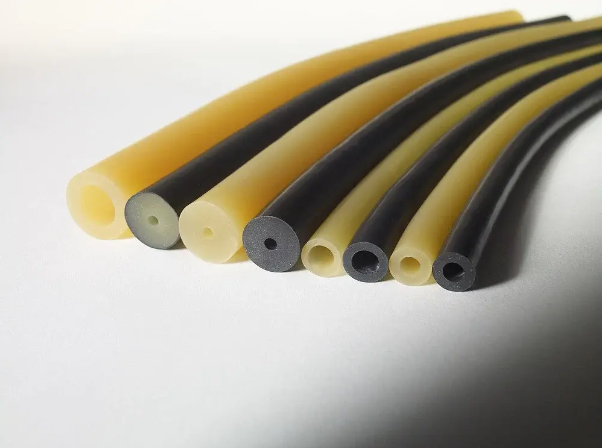

Extruded silicone tubing through China PTFE Tubing manufacturers, is a flexible and heat-resistant solution commonly used in industries that require reliable performance in demanding conditions. Here are some notable features and applications of silicone tubing:

Flexibility and elasticity: Silicone tubing is highly flexible and can be bent, twisted, or stretched without losing its shape or integrity. This makes it suitable for applications that require movement or vibration absorption.

Heat resistance: Silicone tubing can withstand high temperatures, making it ideal for applications involving hot fluids, gases, or steam. It also maintains its flexibility and elasticity in extreme heat conditions.

Chemical resistance: Silicone tubing exhibits excellent resistance to a wide range of chemicals, including acids, bases, solvents, and oils. This resistance ensures that the tubing remains durable and reliable in various industrial environments.

Versatility: Extruded silicone tubing finds applications in industries such as medical, pharmaceutical, food and beverage, and automotive, where its flexibility, heat resistance, and chemical compatibility are essential.

Custom extruded plastic tubing provides a tailored solution for specific industrial needs, offering versatility and adaptability. Here are some key aspects of custom plastic tubing:

Custom shapes and sizes: Extrusion processes allow for the creation of plastic tubing in custom shapes, including rectangular profiles, to meet precise application requirements.

Material options: Custom plastic tubing can be extruded from various materials, such as PVC (polyvinyl chloride), polyethylene, polypropylene, or nylon. This ensures compatibility with specific industrial processes and applications.

Applications: Custom plastic tubing finds applications in industries such as electrical, automotive, packaging, and plumbing, where its customizability and material options make it highly advantageous.

Rectangular extruded aluminum tubing offers a unique shape that provides strength, aesthetics, and versatility in industrial applications. Here are some notable features and benefits of rectangular extruded aluminum tubing:

Strength and stability: Rectangular extruded aluminum tubing offers increased strength and stability compared to other shapes. This makes it suitable for applications that require load-bearing capabilities or structural support.

Aesthetics and design: The clean and sleek lines of rectangular tubing make it a popular choice for architectural and decorative applications. It adds an aesthetic appeal while maintaining structural integrity.

Customizability: Rectangular extruded aluminum tubing can be produced in various sizes and wall thicknesses, allowing for customization to fit specific industrial requirements.

Applications: Rectangular extruded aluminum tubing finds applications in industries such as construction, furniture, transportation, and infrastructure, where its strength, aesthetics, and versatility are highly valued.