литьё резины под давлением

-

Резиновая деталь для литья под давлением

Rubber Injection Molding Спецификация продукта

Место происхождения: Китай

Pipe Material: 100% pure Rubber

Длина: Подгонянный

Shape: customized according to drawing given by customers

Цвет: белый, прозрачный черный, красный, желтый и т.д.

Сертификация: UL, CE, FDA, RoHS, REACH, USP Class VI

Стандарт: ISO9001:2008.

Испытание: SGS прошел

Образец: Бесплатно

Оплата: T/T

Срок службы: Зависит от окружающей среды, пожалуйста, проконсультируйтесь с нашими инженерами.

Применение: Нефтеперевозки, пищевая промышленность, электротехническая промышленность и т.д.

Описание товара

Molded rubber finds widespread applications across industries globally, serving essential roles in vibration isolation, rubber molding, extruded rubber, and rubber-to-metal bonding. The success or failure of standard operations often hinges on the performance of these small but critical rubber products, which are indispensable for vehicles and machinery.

Various specifications dictate the suitable molding process for different applications, ensuring cost-effective solutions and customized rubber products to meet specific needs. Key factors for determining the right fit include size, geometry, weight, material, and volume of parts required.

There are three main categories of rubber molding and application. First, let's examine these categories:

1. Rubber Transfer Molding: Ideal for parts with complex designs or multiple cavities, requiring a closed mold for rubber bonding to metal parts. This process is particularly important for air-free mold cavities.

2. Rubber Compression Molding: An original process utilized for low to medium production volumes, commonly used for seals, O-rings, gaskets, and bulkier parts. It works best for applications with specific production quantity and strong materials, though it may involve lengthy curing times and specific mold requirements.

3. Injection Molding: The most popular and versatile process, involving the use of nozzles and sprues to inject uncured rubber into molds. Different variations of injection molding are available, including organic rubber injection, liquid injection molding (LSR), and thermoplastic rubber injection (TPR).

These molding processes have diverse applications and provide standard solutions for many industries. However, when requirements go beyond standard applications, custom rubber injection molding offers made-to-order solutions that precisely meet unique specifications.

Custom Rubber Литье под давлением provides a solution for businesses and manufacturers with unique part needs, allowing them to achieve cost-efficient and highly effective innovations. RPM Industrial Rubber Parts is a trusted company with over 50 years of experience, offering comprehensive A-Z service for custom rubber parts, silicone rubber components, extrusion, and bonding. With a focus on optimal solutions, RPM Industrial Rubber Parts can help design and create custom engineer plastic products that perfectly match the specific needs of clients. The injection molding supplier ensures a seamless 3-step process, from defining the required part and design to prototyping, production, and prompt shipping, providing clients with top-quality custom rubber parts and exceptional service.

-

Деталь для литья под давлением из витона

Литье под давлением из витона Описание товара

Применение материалов Viton в экстремальных условиях может быть затруднено из-за высокой стоимости. Он обладает низкой вязкостью и ограниченной прочностью на разрыв, если не предпринять некоторые меры по улучшению его свойств. Однако он обладает хорошей ударопрочностью. Кроме того, витон литьё под давлением Обладает отличной термостойкостью и маслостойкостью, поэтому может использоваться для термической смазки в двигателях и компрессорах, а также обладает отличной коррозионной стойкостью, инженерные пластиковые изделия имеет широкие возможности применения в различных концентрированных кислотах.

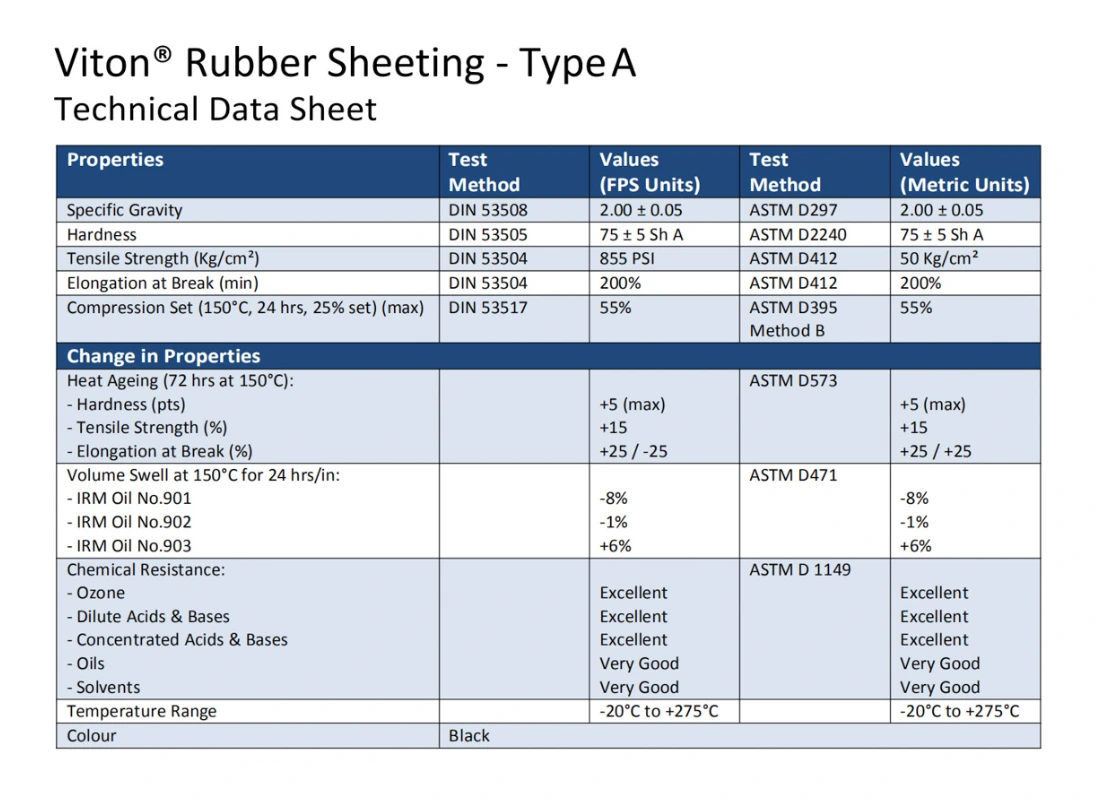

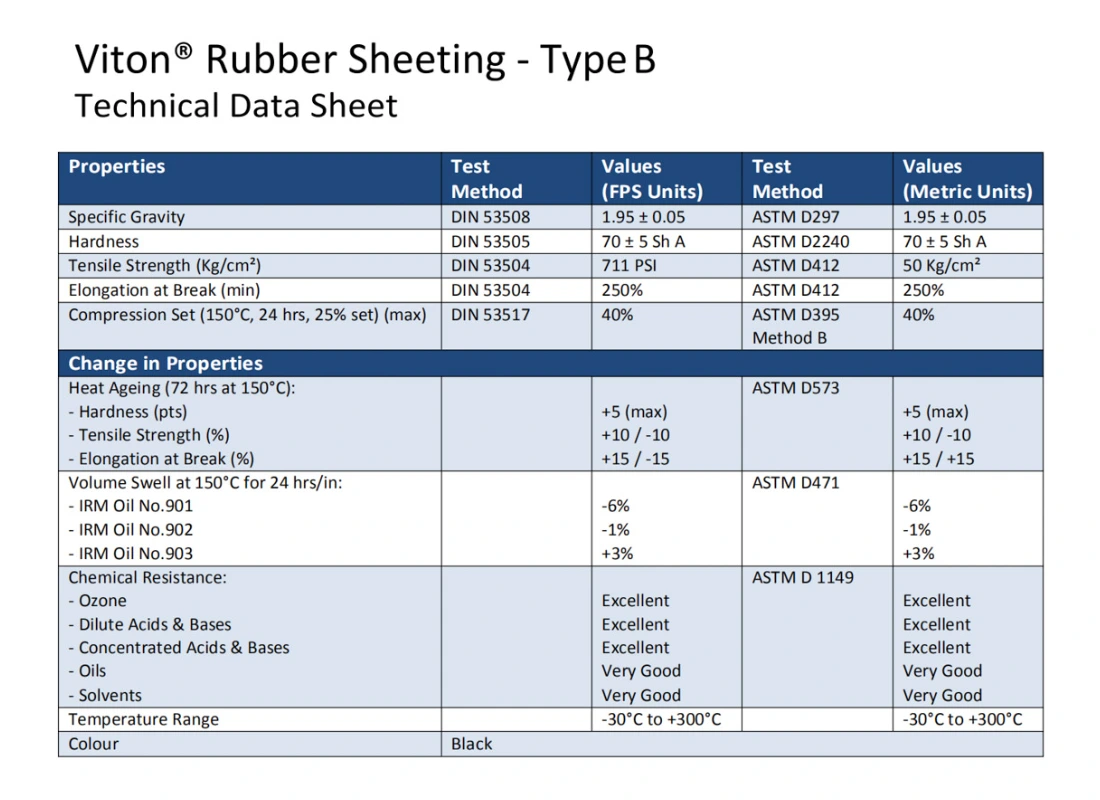

Литье под давлением из витона Спецификация продукта

Полимер: Гексафлуропропилен винилиденфлурид

ISO/ASTM Обозначение: FKM

Рейтинг дюрометра (твердость): 75 (по Шору A)

Диапазон температур: от -18°F до +400°F

Удлинение: 200%

Прочность на разрыв: 1000 PSI

Отделка: Плита, ткань, гладкая бумага

Ширина: 36"

Калибр (толщина): 1/32", 1/16", 3/32", 1/8", 3/16", 1/4"

Чувствительный к давлению клей (PSA): да

Степени: Коммерческий, Viton A, Viton B, Viton F, Viton Extreme

Доступен дополнительный материал прокладки Viton: Да

Место происхождения: Китай

Фирменное наименование: YOZONE производитель резинового литья под давлением

Номер модели: tsmcay-34

Материал трубы: 100% Virgin Viton

Марка материала: Daikin chemical, DuPont. Dongyue & Chenguang (отечественные)

Спецификация: Подгонянный.

Длина: Подгонянный

Толщина: настраивается,

Форма: Круглый

Цвет: черный, индивидуальный

Рабочая температура: -26-232°C (275°C в течение короткого времени)

Допуск: ±0,05 мм

Электрические свойства: Устойчивость к изоляции

Сертификация: UL, CE, FDA, RoHS, REACH.

Стандарт: ISO9001:2008.

Испытание: SGS прошел

Образец: Бесплатно

Оплата: T/T

Срок службы: Зависит от окружающей среды, пожалуйста, проконсультируйтесь с нашими инженерами.

Применение: Аэрокосмическая и электротехническая промышленность

Литье под давлением из витона Возможность поставки:

100000 шт. в месяц Уплотнения и прокладки из витона

Литье под давлением из витона Время выполнения:

Количество (килограммы) 1 - 10 11 - 50 51 - 100 >100 Оценка. Время (дни) 3 5 7 Предстоит согласовать

Литье под давлением из витона Упаковка и доставка

Уплотнения и прокладки из витона в картонной коробке и деревянном поддоне

Порт: Тяньцзинь, Шанхай, Шэньчжэнь, Циндао.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn