Практическое руководство покупателя: 7 ключевых фактов о том, что такое трубки PFA для 2025 года

Сентябрь 16, 2025

Аннотация

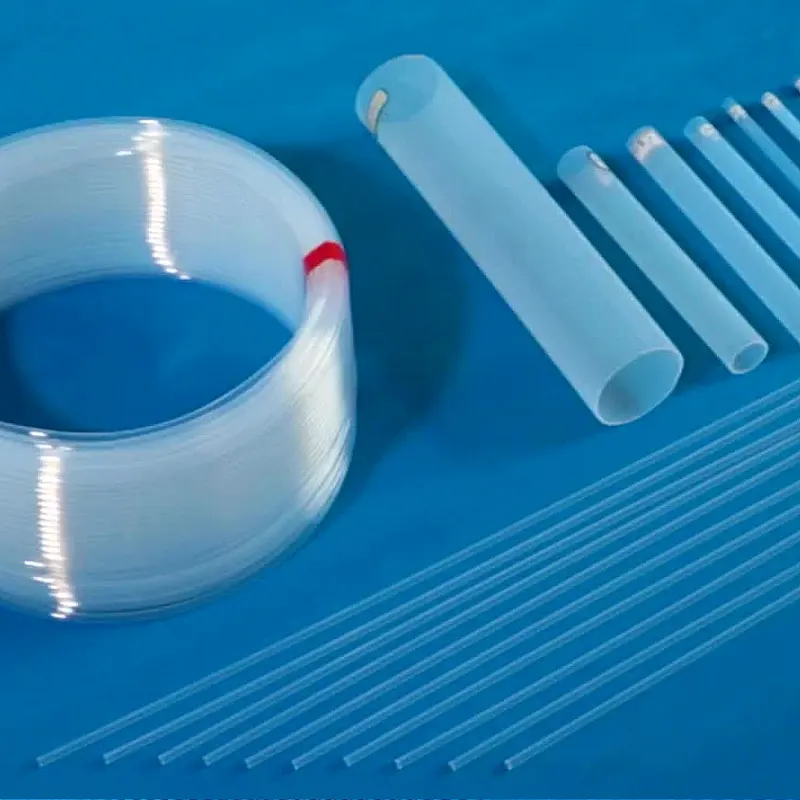

Perfluoroalkoxy alkanes, commonly known as PFA, represent a category of fluoropolymers with a unique combination of properties that distinguish them from other materials in their class, such as polytetrafluoroethylene (PTFE) and fluorinated ethylene propylene (FEP). An examination of PFA tubing reveals its fundamental value in applications demanding extreme chemical inertness, high thermal stability, and exceptional purity. This material is characterized by its fully fluorinated carbon backbone, which is modified by the inclusion of a perfluoroalkoxy side chain. This structural modification allows PFA to be melt-processed using conventional thermoplastic techniques like extrusion and injection molding, a significant advantage over the non-melt-processable PTFE. Consequently, PFA tubing can be manufactured into complex shapes with smooth surfaces and superior clarity. Its continuous service temperature of up to 260°C (500°F), combined with near-universal chemical resistance and low extractable levels, makes it indispensable in industries such as semiconductor manufacturing, pharmaceuticals, and aggressive chemical processing. The material’s robust mechanical properties, including better creep resistance than PTFE, further solidify its position as a premium performance polymer.

Основные выводы

- PFA offers a high continuous service temperature of 260°C, exceeding many other fluoropolymers.

- The material exhibits near-universal chemical resistance, making it ideal for harsh environments.

- Unlike PTFE, PFA is fully melt-processable, allowing for intricate designs and smoother finishes.

- Understanding what is PFA tubing helps in sourcing for high-purity semiconductor and medical uses.

- PFA possesses superior creep resistance and mechanical strength compared to PTFE at elevated temperatures.

- Its low coefficient of friction and non-stick properties prevent contamination and ensure fluid flow.

- PFA features excellent dielectric properties, making it a top choice for electrical insulation.

Оглавление

- Fact 1: Deconstructing the Molecular Architecture of PFA

- Fact 2: The Apex of Chemical Inertness and Purity

- Fact 3: Enduring Extreme Thermal Conditions

- Fact 4: The Transformative Advantage of Melt Processability

- Fact 5: Unseen Excellence in Electrical and Optical Domains

- Fact 6: A Profile of Mechanical Strength and Longevity

- Fact 7: A Practical Framework for Selecting and Applying PFA Tubing

- Frequently Asked Questions About PFA Tubing

- Заключение

- Ссылки

Fact 1: Deconstructing the Molecular Architecture of PFA

To truly grasp the capabilities and limitations of any material, one must begin not with its catalogue of specifications but with its most fundamental identity: its molecular structure. The properties we observe on a macroscopic scale—flexibility, resistance to heat, or inertness to chemicals—are all expressions of the atomic arrangement and the bonds that hold the material together. PFA, or perfluoroalkoxy alkane, is a compelling character in the story of modern polymers, and its tale begins at this molecular level. It belongs to the fluoropolymer family, a group of materials renowned for their extraordinary performance, but it possesses a unique structural feature that sets it apart and defines its specific role in advanced engineering applications.

The Genesis of Fluoropolymers: A Brief History

The journey into the world of fluoropolymers began serendipitously in 1938. A chemist at DuPont, Dr. Roy J. Plunkett, was working with tetrafluoroethylene (TFE) gas for refrigerant development. He discovered that a pressurized cylinder of the gas had seemingly vanished, leaving behind a waxy white powder in its place. Curiosity led him to investigate this mysterious substance. He found it was remarkably slippery and inert to nearly every chemical he tested. The gas had polymerized under pressure, creating polytetrafluoroethylene, or PTFE, which was later commercialized under the famous trade name Teflon.

This discovery opened a new frontier in materials science. PTFE’s properties were revolutionary, but it had one significant drawback: it could not be processed like conventional plastics. It has an extremely high melt viscosity, meaning it does not truly flow when heated. Instead, it had to be processed using techniques more akin to powder metallurgy—compression and sintering—which are costly and limit the complexity of shapes that can be formed. This limitation created a powerful incentive for chemical companies to develop a material that retained PTFE’s remarkable properties but could be more easily fabricated. This quest led to the development of other fluoropolymers, including FEP (fluorinated ethylene propylene) in the 1960s and, crucially, PFA in the early 1970s.

Deconstructing the PFA Molecule: Carbon, Fluorine, and the Ether Linkage

The name “perfluoroalkoxy alkane” itself provides a map to its chemical structure. Let’s break it down. The backbone of the PFA polymer chain, like that of PTFE, is composed of carbon atoms. In a “perfluorinated” polymer, every available bonding site on this carbon backbone that is not used to link to another carbon atom is occupied by a fluorine atom. The bond between carbon and fluorine is the cornerstone of fluoropolymer performance. It is one of the strongest single bonds in organic chemistry, with a bond energy of approximately 485 kJ/mol.

Think of the carbon backbone as a central spine. In PTFE, this spine is sheathed entirely by a dense layer of fluorine atoms. These fluorine atoms are larger than hydrogen atoms and are highly electronegative, meaning they pull electron density toward themselves. This creates a tight, stable, and chemically non-reactive helical sheath around the carbon backbone, effectively protecting it from chemical attack.

Now, how does PFA differ? PFA maintains this fully fluorinated backbone, which is the source of its PTFE-like chemical resistance and thermal stability. The innovation lies in the introduction of a flexible “side chain.” Periodically along the main polymer chain, a bulkier group is attached. This group is a perfluoroalkoxy group, which can be visualized as an oxygen atom (forming an ether linkage, -O-) connected to another short chain of perfluorinated carbon atoms (a perfluoroalkyl group, like -CF3, -C2F5, etc.).

Imagine two long, rigid rods lying next to each other. They pack together very tightly. This is analogous to the chains of PTFE, which allows them to form highly crystalline structures that are difficult to melt and make flow. Now, imagine attaching occasional, flexible side arms to these rods. When you try to pack them together, these side arms get in the way. They disrupt the perfect packing, lowering the crystallinity and creating more space between the main chains. This is precisely what the perfluoroalkoxy side group does in the PFA structure. It acts as a molecular spacer, interrupting the crystalline regularity of the polymer chains. This disruption is the key that unlocks melt processability. It lowers the melt viscosity enough for the material to flow when heated, without significantly compromising the integrity of the powerful C-F bonds that give the material its strength.

How Molecular Structure Dictates Macroscopic Properties

The consequences of this subtle architectural change are profound. The ability to melt and flow means PFA can be extruded into continuous lengths of tubing with very smooth internal and external surfaces. This smoothness is not merely an aesthetic quality; for high-purity fluid handling, a smooth surface minimizes sites for bacterial adhesion and particle entrapment, ensuring the fluid remains uncontaminated.

Furthermore, the slightly lower crystallinity compared to PTFE results in improved optical clarity. While PTFE is generally opaque and white, PFA tubing can be manufactured to be transparent. This allows for visual inspection of the fluid flow within the tube, a valuable feature for monitoring processes and diagnosing issues like blockages or air bubbles.

The ether linkage (-O-) in the side chain also imparts a small degree of flexibility to the polymer structure. While the C-F bonds are rigid, the C-O-C ether bond can rotate. This contributes to PFA having slightly better flexibility and stress-crack resistance than FEP at elevated temperatures. Perhaps most importantly, the melt-processable nature of PFA allows for the fusion welding of tubes and fittings, creating monolithic, leak-proof systems without the need for mechanical seals that can fail or introduce contaminants.

PFA’s Place in the Fluoropolymer Family

To contextualize PFA, it is helpful to see it as occupying a specific niche within the broader fluoropolymer family.

- PTFE (политетрафторэтилен): The original. It has the highest service temperature and the best chemical resistance in most cases. Its major limitation is its lack of melt processability.

- FEP (фторированный этилен-пропилен): A copolymer of TFE and hexafluoropropylene. It was the first melt-processable alternative to PTFE. It offers similar chemical resistance but has a lower service temperature (around 200°C) and is more susceptible to stress cracking under certain conditions.

- ПФА (перфторалкоксиалкан): Designed to bridge the gap. It combines the melt processability of FEP with a service temperature and chemical resistance that are very close to those of PTFE. It also boasts better mechanical properties at high temperatures, such as creep resistance, than both PTFE and FEP.

- ETFE (Ethylene Tetrafluoroethylene): A copolymer of ethylene and TFE. It is not fully fluorinated, as it contains C-H bonds. This makes it mechanically tougher and more abrasion-resistant than PFA or FEP, but it comes at the cost of a lower service temperature and reduced chemical resistance.

In essence, PFA was engineered to be the “best of both worlds”: retaining the superlative performance of PTFE while offering the fabrication ease of a conventional thermoplastic. This molecular design choice makes PFA tubing not just another plastic tube, but a highly engineered solution for problems that other materials simply cannot solve.

Fact 2: The Apex of Chemical Inertness and Purity

When we speak of a material’s utility in demanding environments, particularly those involving aggressive chemicals or requiring absolute cleanliness, two properties rise above all others: chemical inertness and purity. For PFA tubing, these are not merely features; they are its defining characteristics, the very reason for its existence and its adoption in the world’s most advanced industries. This exceptional performance is not a matter of chance but a direct consequence of the material’s fundamental molecular structure, which creates a nearly impenetrable fortress against chemical attack and contamination.

The Strength of the Carbon-Fluorine Bond

At the heart of PFA’s chemical resistance is the carbon-fluorine (C-F) bond. As mentioned before, this covalent bond is exceptionally strong and stable. To put this into perspective, the energy required to break a C-F bond is significantly higher than that for a carbon-hydrogen (C-H) bond found in common plastics like polyethylene, or a carbon-chlorine (C-Cl) bond found in PVC. Chemicals typically react by breaking and forming bonds. Since the C-F bond is so difficult to break, most chemicals lack the energy to initiate a reaction with the polymer chain.

Moreover, the fluorine atoms are relatively large and highly electronegative. They form a dense, helical sheath around the carbon backbone of the polymer. This sheath serves two purposes. First, it physically shields the more vulnerable carbon backbone from being reached by reactive molecules. Imagine a castle wall so thick and well-guarded that attackers cannot even get close to the inner keep. Second, the high electronegativity of the fluorine atoms pulls electron density away from the carbon backbone, making it less susceptible to attack by electron-seeking reagents (electrophiles) or electron-donating reagents (nucleophiles). This combination of bond strength and steric shielding makes the PFA molecule exceptionally stable and non-reactive.

Resistance Across the Chemical Spectrum: Acids, Bases, and Solvents

The practical result of this molecular stability is that PFA tubing exhibits near-universal chemical resistance. It remains unaffected by the most aggressive substances that would readily destroy lesser materials. This includes:

- Strong Acids: Concentrated sulfuric, nitric, hydrochloric, and even hydrofluoric acid (one of the most corrosive acids known) have virtually no effect on PFA at typical operating temperatures.

- Strong Bases: Solutions of sodium hydroxide, potassium hydroxide, and other caustic substances do not cause swelling, degradation, or chemical change.

- Aggressive Solvents: A wide range of organic solvents, from hydrocarbons and alcohols to chlorinated solvents, ketones, and esters, can be transported through PFA tubing without risk of the tubing dissolving, swelling, or leaching impurities.

- Oxidizing Agents: Powerful oxidizers like halogens (chlorine, bromine), peroxides, and ozone do not degrade the polymer.

There are only a few, very specific exceptions to this rule, and they are typically encountered only in extreme laboratory or industrial conditions. These include molten alkali metals (like sodium), certain complex halogenated compounds at very high temperatures and pressures, and elemental fluorine gas itself. For over 99% of industrial and laboratory applications, PFA is considered effectively inert.

This inertness ensures the long-term integrity of the fluid handling system. The tubing will not soften, become brittle, or fail prematurely due to chemical exposure, guaranteeing operational safety and reliability.

| Характеристика | ПФА (перфторалкокси) | PTFE (политетрафторэтилен) | FEP (фторированный этилен-пропилен) |

|---|---|---|---|

| Химическая стойкость | Excellent; resistant to nearly all chemicals, acids, bases, and solvents. | Excellent; considered the most chemically inert polymer. | Excellent; very similar to PFA and PTFE, with few exceptions. |

| Purity (Extractables) | Very High; extremely low levels of ionic and organic extractables. | High; low extractables but surface can be porous, trapping particles. | High; low extractables, smoother surface than sintered PTFE. |

| Surface Smoothness | Excellent; melt extrusion creates a very smooth, non-porous surface. | Fair to Good; sintering process can result in a more porous surface texture. | Very Good; melt extrusion produces a smooth surface. |

| Biocompatibility | Excellent; meets USP Class VI and ISO 10993 standards. | Excellent; meets USP Class VI and ISO 10993 standards. | Excellent; meets USP Class VI and ISO 10993 standards. |

| Primary Application | High-purity semiconductor, pharmaceutical, and aggressive chemical handling. | General chemical processing, seals, liners where melt processing isn’t needed. | Chemical processing, labware, wire insulation where temperatures are below 200°C. |

Purity in Practice: The Semiconductor Industry’s Demands

Beyond simply resisting chemical attack, PFA tubing is prized for what it doesn’t do: it does not contaminate the fluid it carries. This concept of purity is paramount in industries like semiconductor manufacturing. A modern microprocessor is built on a silicon wafer through hundreds of steps involving ultra-pure chemicals, deionized water, and reactive gases. Even minuscule contamination can ruin a chip. A single stray metallic ion, for example, can alter the electrical properties of a transistor, leading to a defect. A microscopic particle can block the light used in photolithography, ruining an entire circuit.

This is where the purity of PFA tubing becomes indispensable. High-purity grades of PFA are manufactured in cleanroom environments using carefully selected raw materials. The resulting tubing has exceptionally low levels of “extractables”—trace substances that can leach out of the polymer and into the fluid. These extractables can include metallic ions (like sodium, iron, or calcium), anions (like fluoride or chloride), and total organic carbon (TOC). In high-purity PFA, the concentration of these contaminants is measured in parts per billion (ppb) or even parts per trillion (ppt).

The smooth, melt-processed inner surface of PFA tubing further enhances its purity. Unlike sintered PTFE, which can have a microporous surface that traps particles and microorganisms, the glass-like finish of PFA tubing minimizes adhesion and allows for complete flushing and cleaning. This is why PFA is the material of choice for “wet bench” equipment in semiconductor fabs, used to transport everything from hydrofluoric acid for etching to ultra-pure deionized water for rinsing. Using a material like virgin transparent extruded tubing for semiconductors ensures that the only thing touching the silicon wafer is the intended chemical, in its purest form.

Biocompatibility and Its Role in Medical and Pharmaceutical Fields

The same combination of chemical inertness and high purity makes PFA tubing an excellent choice for medical and pharmaceutical applications. “Biocompatibility” is the property of a material being compatible with living tissue; it does not provoke an adverse response, such as an immune reaction or toxic effect. PFA, being chemically inert, does not react with bodily fluids or sensitive drug formulations.

Many grades of PFA are tested and certified to meet stringent regulatory standards like USP Class VI and ISO 10993. These tests ensure the material is non-toxic, non-hemolytic (does not damage red blood cells), and non-pyrogenic (does not cause fever). This makes it suitable for a range of applications:

- Pharmaceutical Manufacturing: Transporting active pharmaceutical ingredients (APIs), cell culture media, and high-purity water (Water-for-Injection or WFI). Its non-stick surface prevents costly product from adhering to the tube walls, improving yield.

- Медицинские приборы: Use in fluid paths for diagnostic equipment, surgical devices, and certain short-term implantable components where inertness is paramount.

- Analytical Laboratories: Handling sensitive samples for chromatography (like HPLC) or spectroscopy, where any leached impurity from the tubing would interfere with the measurement and invalidate the results.

In these fields, the integrity of the product or the safety of the patient is non-negotiable. The steadfast, non-reactive nature of PFA provides a level of assurance that few other materials can match. It acts as a silent, invisible guardian, ensuring that the fluid within remains exactly as it is intended to be—pure and unadulterated.

Fact 3: Enduring Extreme Thermal Conditions

A material’s response to temperature is a critical determinant of its utility. For many polymers, heat is an adversary, causing them to soften, melt, degrade, or lose their structural integrity. Fluoropolymers, and PFA in particular, are defined by their remarkable ability to not just survive but to function effectively at temperatures that would be catastrophic for most other plastics. This high-temperature performance is not an incidental benefit; it is a core feature that enables PFA tubing to be used in demanding applications like chemical reactors, heat exchangers, and steam lines.

Defining Thermal Stability: What “High Temperature” Means for Polymers

When we discuss a polymer’s performance at “high temperature,” we are referring to several distinct but related concepts. The most common metric is the continuous service temperature. This is the maximum temperature at which the material can operate continuously for its expected service life without significant degradation of its key properties (like tensile strength or chemical resistance).

Beyond this, we might also consider the short-term peak temperature, which the material can withstand for brief periods. Another important factor is the heat deflection temperature (HDT), which measures the temperature at which a standard test bar of the material deforms under a specific load. Finally, we must understand how a material’s mechanical properties, such as its strength and stiffness, change as the temperature increases. A material might not melt, but it could become too soft to perform its function.

For PFA, its exceptional thermal stability is, once again, rooted in the strength of the carbon-fluorine bond. A great deal of thermal energy is required to vibrate these bonds to the point of breaking. This inherent stability of the polymer chain itself is what allows PFA to maintain its chemical identity and structure at elevated temperatures.

Continuous Service Temperature of PFA Tubing

The widely accepted continuous service temperature for PFA is 260°C (500°F). This is a remarkable figure for a thermoplastic polymer. To provide some context:

- Polyethylene (PE), used in common plastic bags and bottles, begins to soften significantly above 80°C (176°F).

- Polyvinyl Chloride (PVC), used for household pipes, is generally limited to around 60°C (140°F).

- Polycarbonate (PC), a tougher engineering plastic, has a continuous service limit of about 120°C (248°F).

- Nylon (PA), used in mechanical parts, can typically handle up to 85-150°C (185-302°F) depending on the grade and conditions.

PFA’s ability to operate continuously at 260°C places it in an elite class of polymers. This means it can be used for applications involving high-temperature chemical synthesis, steam-in-place (SIP) sterilization cycles common in the pharmaceutical industry (typically at 121-134°C), or for transporting hot, corrosive fluids in industrial plants. This high-temperature capability, combined with its chemical inertness, creates a synergy that solves many engineering challenges at once.

Comparing Thermal Limits: PFA vs. FEP and PTFE

Understanding PFA’s thermal performance is best done by comparing it to its closest relatives in the fluoropolymer family. This comparison illuminates the specific trade-offs and advantages that guide material selection.

| Недвижимость | ПФА (перфторалкокси) | PTFE (политетрафторэтилен) | FEP (фторированный этилен-пропилен) |

|---|---|---|---|

| Continuous Service Temp. | 260°C (500°F) | 260°C (500°F) | 200°C (392°F) |

| Melt Point (Approx.) | ~305°C (581°F) | ~327°C (621°F) | ~260°C (500°F) |

| Melt Processability | Yes (Extrusion, Injection Molding) | No (Sintering, Ram Extrusion) | Yes (Extrusion, Injection Molding) |

| Creep Resistance | Good (Better than PTFE) | Fair (Prone to cold flow) | Fair to Good (Less than PFA) |

| Tensile Strength @ 250°C | ~4 MPa | ~2 MPa | Not Recommended for Use |

| Optical Clarity | Good to Excellent (Transparent) | Poor (Opaque) | Excellent (Transparent) |

As the table shows, both PFA and PTFE share the same nominal continuous service temperature of 260°C. They are the top performers in this regard. FEP, while still a high-performance material, has a significantly lower limit of 200°C. This 60°C difference is substantial and often makes PFA the necessary choice for applications that operate in the 200-260°C range. You might ask, if PFA and PTFE have the same temperature rating, why choose PFA? The answer lies in the interplay between temperature and other properties.

The Impact of Temperature on Mechanical Properties (Creep and Strength)

A material’s temperature rating is not the full story. We must also consider how its mechanical strength behaves at that temperature. While PTFE does not chemically degrade at 260°C, it becomes significantly softer and is much more prone to a phenomenon called creep (or “cold flow”). Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress.

PFA, due to its slightly different molecular structure and chain entanglement, exhibits significantly better creep resistance and retains a higher proportion of its room-temperature strength at elevated temperatures compared to PTFE. For example, at 250°C, PFA has roughly double the tensile strength of PTFE.

Let’s imagine a practical scenario: a tube carrying a fluid under pressure at 240°C. A PTFE tube, while not melting, might slowly expand or deform over time at a fitting, eventually leading to a leak. A PFA tube under the same conditions would maintain its shape and dimensional stability far more effectively. This superior mechanical performance at high temperatures is a primary reason why engineers often specify PFA over PTFE, even when the temperature is within PTFE’s rated limit. They are choosing PFA not just for its thermal stability, but for its thermo-mechanical stability. The availability of diverse high-performance FEP and PFA tubing options allows engineers to select the optimal balance of thermal performance and processability for their specific needs.

In essence, PFA offers a robust and reliable solution for hot, demanding environments. It provides the thermal ceiling of PTFE while delivering superior mechanical integrity under load, ensuring that fluid handling systems remain secure and functional when the heat is on.

Fact 4: The Transformative Advantage of Melt Processability

In the world of polymer engineering, how a material is formed into a useful object is just as important as the intrinsic properties of the material itself. The most remarkable substance is of little practical value if it cannot be shaped efficiently and reliably. This is the central challenge that PFA was designed to overcome within the fluoropolymer family. While PTFE set the benchmark for performance, its resistance to conventional processing methods was a significant hurdle. PFA’s ability to be melt-processed represents a fundamental leap forward, transforming it from a high-performance powder into a versatile and manufacturable engineering material.

The Processing Challenge of PTFE (Sintering)

To appreciate the innovation of PFA, one must first understand the difficulty of working with PTFE. When you heat most common plastics (thermoplastics), they reach a melting point where they transform from a solid into a viscous liquid. In this liquid state, they can be pushed through a die to form a tube (extrusion), forced into a mold to create a complex part (injection molding), or even welded together.

PTFE defies this behavior. It has an exceptionally high melt viscosity—so high that even well above its crystalline melting point of ~327°C, it does not flow like a liquid. It behaves more like a very soft, gelatinous solid. It cannot be processed using conventional thermoplastic equipment. Instead, PTFE fabrication relies on a multi-step process:

- Compression: Fine PTFE powder is compressed into a desired pre-form shape (like a solid billet or a thick-walled tube) under high pressure at room temperature.

- Sintering: This pre-form is then heated in an oven to a temperature above its melting point. The individual polymer particles fuse together during this step, but the material does not flow. This is analogous to how ceramic parts are fired in a kiln.

- Cooling: The sintered part is then cooled under controlled conditions to achieve the desired final properties.

For tubing, a specialized variant called paste extrusion or ram extrusion is used, where a lubricant is mixed with the PTFE powder, extruded into a shape, and then heated to remove the lubricant and sinter the polymer. These processes are slower, more energy-intensive, and less versatile than standard melt-processing. They make it difficult to produce very long, continuous lengths of tubing, to achieve very thin walls, or to create complex internal or external profiles. The resulting surface finish is also inherently more porous than that of a melt-extruded part.

PFA’s Solution: A True Thermoplastic

PFA was meticulously engineered to solve this problem. As discussed earlier, the introduction of the bulky perfluoroalkoxy side groups along the polymer chain disrupts the tight packing of the main chains. This modification has a critical effect: it dramatically lowers the melt viscosity of the polymer. While still more viscous than many common plastics, PFA’s melt viscosity is low enough—by several orders of magnitude compared to PTFE—to allow it to be processed on standard thermoplastic machinery.

When heated above its melting point of around 305°C, PFA transforms into a genuine, albeit thick, fluid. This means it behaves as a true thermoplastic. This single characteristic opens up a world of manufacturing possibilities that are closed to PTFE. It fundamentally changes the economics and design freedom associated with high-performance fluoropolymers.

Extrusion, Injection Molding, and Welding of PFA

The melt-processable nature of PFA enables a range of efficient, high-precision fabrication techniques:

- Melt Extrusion: This is the primary method for producing PFA tubing. PFA resin pellets are fed into a heated barrel containing a rotating screw. The screw melts, mixes, and conveys the polymer forward, forcing it through a circular die. The extruded tube then passes through a cooling bath to solidify it before being coiled onto a spool. This is a continuous process that can produce thousands of feet of seamless tubing with excellent dimensional control and a very smooth surface finish. It allows for the production of tubing with much tighter tolerances and thinner walls than is possible with PTFE.

- Injection Molding: For complex, three-dimensional parts like fittings, valve bodies, or pump components, injection molding is used. Molten PFA is injected under high pressure into a precisely machined mold cavity. This allows for the creation of intricate shapes with integrated features, reducing the need for subsequent machining or assembly.

- Welding: Perhaps one of the most significant advantages is the ability to weld PFA. Using specialized tools that employ heat (such as infrared or hot gas welders), two pieces of PFA—like a tube and a fitting—can be fused together. The material at the interface is melted and allowed to intermingle and re-solidify, creating a permanent, monolithic bond. This fusion weld is as strong and chemically resistant as the parent material itself. It eliminates the need for mechanical joints that use threads or compression ferrules, which can be potential leak points or sources of contamination. This is especially valuable in high-purity semiconductor and pharmaceutical systems where system integrity is non-negotiable.

Implications for Complex Geometries and Leak-Free Systems

The practical consequences of PFA’s melt processability are far-reaching. Engineers are no longer constrained by the limitations of sintering. They can design and build systems that are more complex, more reliable, and often more cost-effective in the long run.

- Design Freedom: PFA can be molded into custom components tailored to a specific application. This could be a multi-port valve block that consolidates several connections into one piece, or a sensor housing with intricate internal passages.

- System Integrity: The ability to fusion-weld components creates a seamless fluid path. In an ultra-high-purity chemical delivery system, every mechanical joint is a risk. It’s a place where particles can be generated from friction, where microbes can colonize in tiny crevices, and where leaks can occur due to vibration or thermal cycling. A fully welded PFA system mitigates these risks, providing the highest possible level of cleanliness and safety.

- Surface Quality: Melt extrusion produces an exceptionally smooth, mirror-like internal surface. This “Ra” (Roughness average) value can be significantly lower than that of sintered PTFE. A smoother surface is easier to clean, drains more completely, and reduces the potential for particle shedding and contamination.

In summary, while PFA’s chemical and thermal properties are what make it a high-performance material, its melt processability is what makes it a practical and versatile engineering solution. It democratized the performance of top-tier fluoropolymers, allowing them to be shaped and assembled with the same ease and precision as more conventional plastics, thereby enabling the creation of the sophisticated, high-purity systems that underpin modern technology.

Fact 5: Unseen Excellence in Electrical and Optical Domains

While PFA tubing is most famous for its performance in fluid handling, its portfolio of properties extends into other physical domains, particularly electricity and optics. These characteristics may be “unseen” in a typical chemical transport application, but they are of paramount importance in fields like electronics, telecommunications, and sensor technology. PFA’s unique molecular structure, which makes it so chemically inert, also endows it with exceptional electrical insulating properties and useful optical characteristics, making it a multi-talented material for advanced engineering designs.

Low Dielectric Constant and Dissipation Factor

To understand PFA’s electrical prowess, we must first touch upon two key concepts: dielectric constant and dissipation factor.

The dielectric constant (or relative permittivity) is a measure of a material’s ability to store electrical energy when it is placed in an electric field. A low dielectric constant means the material does not store much energy and, more importantly, does not significantly interfere with a high-frequency electrical signal passing through or near it. For high-speed data transmission, a low dielectric constant is highly desirable because it allows signals to travel faster and with less distortion.

The dissipation factor (or loss tangent) measures the inefficiency of an insulating material. It quantifies how much of the electromagnetic energy is absorbed by the material and lost as heat. A low dissipation factor means the material is a very efficient insulator, wasting very little energy. This is especially critical in high-frequency applications, where a high dissipation factor would lead to excessive heat buildup and signal loss.

PFA excels in both of these areas. Its electrical properties are a direct result of its molecular structure. The C-F bonds are very strong and not easily polarized (distorted) by an electric field. The symmetry of the fluorinated polymer chain results in a very low overall polarity. Consequently, PFA has one of the lowest dielectric constants (around 2.1) and one of the lowest dissipation factors of any solid material. These values are also remarkably stable across a wide range of frequencies (from DC up to the gigahertz range) and temperatures.

High Dielectric Strength: PFA as an Insulator

Another critical electrical property is dielectric strength. This measures the maximum electric field an insulating material can withstand without “breaking down” and starting to conduct electricity. A material with high dielectric strength is a robust insulator, capable of preventing electrical arcing even at very high voltages.

PFA possesses a very high dielectric strength. The same strong, stable C-F bonds that provide chemical resistance also make it very difficult for electrons to be stripped away or to move through the material. This makes PFA tubing an excellent choice for insulating high-voltage wires, especially in environments where chemical or thermal resistance is also required. For instance, it can be used as a protective sleeve for wiring inside a chemical processing plant or as the primary insulation for specialized, high-performance cables.

Optical Clarity and UV Resistance

While PTFE is opaque, PFA’s melt-processable nature and lower crystallinity allow it to be manufactured with excellent optical clarity. PFA tubing can be made highly transparent, particularly in the visible and ultraviolet (UV) spectra. This transparency is not just for visual inspection of fluid flow. It enables a range of specialized applications:

- UV Sterilization: In pharmaceutical or water treatment systems, UV light is often used to sterilize fluids. PFA tubing is transparent to the germicidal wavelengths of UV light (around 254 nm), allowing the fluid to be irradiated as it flows through the tube. Many other plastics would either block the UV light or be rapidly degraded by it.

- Photochemical Reactors: For chemical reactions that are initiated by light, clear PFA tubing can be coiled around a light source to create an efficient photoreactor. Its chemical inertness ensures it will not react with the precursors or products.

- Sensor Housings: PFA can be used to protect optical sensors that need to be immersed in corrosive fluids. The PFA acts as a transparent, protective window.

Furthermore, PFA exhibits excellent resistance to degradation from long-term UV exposure. The high energy of UV radiation can break the chemical bonds in many polymers, causing them to become brittle, discolored, and weak. The immense strength of the C-F bond, however, is greater than the energy carried by UV photons. As a result, PFA tubing can be used in outdoor applications or in processes with intense UV light sources without significant loss of its mechanical or optical properties over time.

Applications in Electronics and Advanced Cabling

The combination of these properties makes PFA a material of choice in the electronics and telecommunications industries.

- High-Frequency Coaxial Cables: In cables designed to carry high-frequency signals (like those for radar, satellite communications, or 5G infrastructure), the insulator separating the center conductor from the outer shield is critical. PFA’s low dielectric constant and low dissipation factor minimize signal loss and distortion, ensuring signal integrity over long distances.

- Plenum-Rated Cabling: “Plenum” refers to the air-handling space in buildings (e.g., above a dropped ceiling). Cables installed in this space must meet strict fire safety codes. They must not propagate a flame and must produce very little smoke when exposed to fire. PFA has excellent flame retardancy (a Limiting Oxygen Index of >95%) and produces very little smoke, allowing it to be used for the insulation of plenum-rated data and communication cables.

- Semiconductor Equipment Wiring: Inside the complex machinery used to manufacture microchips, wiring is often exposed to corrosive chemical vapors and high temperatures. PFA-insulated wires provide the necessary electrical performance along with the chemical and thermal resilience to survive in this harsh environment.

In these contexts, PFA tubing and insulation are not merely passive components; they are active enablers of high performance. They ensure that signals remain clean, power is delivered safely, and processes function reliably, demonstrating a versatility that goes far beyond simple fluid transport.

Fact 6: A Profile of Mechanical Strength and Longevity

A material’s ability to resist chemical attack and high temperatures is of little use if it cannot physically withstand the stresses and strains of its intended application. The mechanical properties of a material—its strength, flexibility, and durability over time—determine its structural integrity. PFA tubing exhibits a robust mechanical profile that complements its chemical and thermal excellence. It is not as rigid as metal, nor as tough as some engineering plastics like PEEK, but it offers a unique combination of strength, creep resistance, and surface properties that ensure its reliability and longevity in demanding service.

Tensile Strength and Elongation at Break

Two of the most fundamental mechanical properties are tensile strength and elongation. Прочность на разрыв is the maximum stress a material can withstand while being pulled or stretched before it breaks. Удлинение при разрыве is the measure of how much the material can stretch as a percentage of its original length before failing. Together, these properties tell us about a material’s strength and ductility.

At room temperature, PFA has a respectable tensile strength, typically in the range of 28-31 MPa (4000-4500 psi). This is sufficient for most fluid handling applications where the tubing is properly supported. Its elongation at break is also high, usually around 300%. This high elongation indicates that PFA is not a brittle material; it can deform significantly before it fractures. This is a valuable safety feature, as it means a tube under excessive stress is more likely to stretch and deform, providing a visual warning of impending failure, rather than shattering suddenly.

What is particularly noteworthy, as mentioned previously, is PFA’s retention of these properties at elevated temperatures. While all polymers get weaker as they get hotter, PFA maintains a greater proportion of its strength at high temperatures compared to FEP and, crucially, exhibits much better structural integrity than PTFE under load.

Creep Resistance Under Load and Temperature

Perhaps the most significant mechanical advantage of PFA over PTFE is its superior resistance to creep. Creep, sometimes called cold flow, is the slow, continuous deformation of a material under a constant load. It is a major concern in applications involving sealing, gaskets, and tubing connections.

Imagine a PFA tube connected to a valve using a compression fitting. The fitting works by squeezing a ferrule onto the outside of the tube, creating a seal. This creates a constant compressive stress on the tubing. A material with poor creep resistance, like PTFE, will slowly flow or deform away from this pressure point over time. This can cause the fitting to loosen, leading to a leak. This process is accelerated significantly at higher temperatures.

PFA’s molecular structure, with its entangled chains and side groups, is more resistant to this slow deformation. Under the same conditions of pressure and temperature, a PFA tube will maintain its shape and the integrity of the seal for much longer than a PTFE tube. This makes PFA the preferred choice for any application where long-term, leak-free connections are critical, especially when thermal cycling (repeated heating and cooling) is involved. Thermal cycling can exacerbate creep-related failures, as the material expands and contracts, and PFA’s stability provides a much more reliable seal.

Low Coefficient of Friction and Non-Stick Surface

Like all fluoropolymers, PFA has an exceptionally low coefficient of friction. Its surface is incredibly slippery, second only to PTFE. The coefficient of friction of PFA against polished steel is very low, typically around 0.2. This property has several practical benefits:

- Low Flow Resistance: Fluids flow through PFA tubing with minimal frictional losses, which can be an advantage in low-pressure or gravity-fed systems.

- Non-Stick Properties: The low surface energy of PFA means that very few substances will stick to it. This is invaluable in many applications. In pharmaceutical manufacturing, it prevents expensive drug products from adhering to the tube walls, maximizing product yield. In food processing, it prevents buildup of food residues and facilitates easy cleaning. In paint or adhesive dispensing, it prevents the material from clogging the lines.

- Self-Lubricating: For applications where tubing might be routed through a guide or be subject to abrasion, its low friction surface reduces wear and tear.

This non-stick, or hydrophobic/oleophobic, character is another manifestation of its stable, low-energy fluorinated surface.

Weatherability and Long-Term Environmental Exposure

Durability is not just about resisting an immediate load; it is about resisting degradation over years of service. PFA demonstrates outstanding long-term durability, often referred to as “weatherability.” As discussed in the context of its optical properties, PFA is virtually immune to degradation from UV radiation. This means it can be used outdoors without becoming brittle or discolored like many other plastics.

Furthermore, it does not absorb water. Many polymers, like nylon, will absorb moisture from the atmosphere, which can cause them to swell and change their dimensions and mechanical properties. PFA is completely hydrophobic; its properties remain consistent regardless of the ambient humidity. This dimensional stability is crucial for maintaining tight tolerances in precision equipment.

This combination of UV resistance and non-hygroscopic behavior means that a PFA component will have virtually the same properties on the day it is retired from service as it did on the day it was installed, even after years of exposure to sunlight, rain, and humidity. This long-term stability reduces maintenance costs and ensures predictable, reliable performance throughout the life of the system. In essence, PFA’s mechanical profile is one of endurance and reliability, providing the physical backbone needed to support its extraordinary chemical and thermal capabilities.

Fact 7: A Practical Framework for Selecting and Applying PFA Tubing

Knowing the theoretical properties of PFA is one thing; successfully applying it in a real-world system is another. The final step in understanding what is PFA tubing involves moving from the “what” to the “how.” The selection and implementation of PFA tubing require careful consideration of the application’s specific demands, an awareness of potential failure modes, and adherence to best practices for installation. This practical framework helps bridge the gap between material science and sound engineering, ensuring that the remarkable potential of PFA is fully realized.

Identifying the Right Grade of PFA for Your Application

Not all PFA is created equal. Manufacturers produce different grades of PFA resin tailored for specific performance characteristics. Choosing the right grade is the first and most critical decision.

- Standard Industrial Grade: This is a general-purpose grade suitable for a wide range of chemical processing applications where high chemical resistance and thermal stability are the primary requirements. It offers a good balance of performance and cost.

- High-Purity (HP) and Ultra-High-Purity (UHP) Grades: These are the grades specified for the semiconductor, pharmaceutical, and biotechnology industries. They are produced from select resins and manufactured in cleanroom environments to minimize contamination. These grades come with certifications detailing the extremely low levels of metallic and organic extractables. The cost is higher, but it is non-negotiable for applications where purity is paramount.

- High Flex Life Grades: Some applications involve repeated flexing or bending, such as in robotic equipment or peristaltic pumps. Specialized PFA grades are available that are modified to have enhanced flexural endurance, resisting stress cracking under cyclic loading.

- Weldable Grades: While most PFA is weldable, some grades are specifically optimized for certain welding techniques (like infrared welding) to ensure the strongest and most consistent bonds.

The selection process should begin with a thorough analysis of your system’s requirements. What is the most aggressive chemical it will see? What is the maximum operating temperature and pressure? Is purity a concern? Is the tubing subject to mechanical flexing? Answering these questions will guide you to the appropriate grade.

Common Failure Modes and How to Prevent Them

Even a high-performance material like PFA can fail if misapplied. Understanding the common failure modes is key to designing a robust system.

- Kinking: PFA tubing, like all semi-rigid tubing, has a minimum bend radius. If it is bent too sharply, it can kink. A kink creates a stress concentration point that is prone to fracture, and it severely restricts flow. Prevention is simple: always respect the manufacturer’s specified minimum bend radius. If tight turns are necessary, use pre-formed elbows or fittings designed for 90-degree transitions.

- Creep-Related Leakage at Fittings: As discussed, even though PFA has good creep resistance, it is not zero. In high-temperature applications under constant pressure, fittings can loosen over time. Prevention involves using the correct type of fitting (flare fittings are often preferred over compression fittings for high-purity and high-temperature work), proper installation torque, and periodic inspection and re-tightening as part of a preventative maintenance schedule.

- Abrasion: While PFA is durable, its surface is relatively soft compared to metals. If it is routed in a way that allows it to rub against a sharp or abrasive surface, it can wear through over time. Prevention involves proper routing and clamping of the tubing. In areas of high vibration, using protective sleeves or grommets can prevent abrasive wear.

- Exceeding Pressure/Temperature Limits: Every tube has a pressure rating that decreases as temperature increases. Manufacturers provide charts detailing the maximum working pressure at various temperatures. It is imperative to operate within these limits, including a suitable safety factor. A pressure surge or temperature spike beyond the material’s rating can lead to bursting.

Installation Best Practices: Fittings, Bending, and Support

Proper installation is the final piece of the puzzle. A multi-million dollar system can be compromised by a single poorly made connection.

- Резка: Always use a specialized tube cutter designed for plastic tubing. This ensures a clean, square cut that is perpendicular to the tube’s length. A jagged or angled cut, often made with a knife, will not seal properly in a fitting.

- Фурнитура: For PFA, several types of fittings are common.

- Compression Fittings: These are common and easy to use but can be a point of creep-related failure at high temperatures. They work by compressing a ferrule onto the tube’s outer diameter.

- Flare Fittings: These are generally considered superior for high-purity and secure applications. The end of the tube is heated and formed into a 45-degree flare using a special tool. This flared surface then seals against a matching surface in the fitting. This creates a seal with a large surface area and minimizes stress on the tube.

- Fusion Welding: As mentioned, this provides the ultimate in leak-proof, high-purity connections by creating a seamless, monolithic system. It requires specialized equipment and trained technicians but offers unparalleled reliability.

- Support: PFA tubing is not self-supporting like metal pipe. It must be properly supported along its length with clamps or in a tray to prevent sagging. Sagging can create low points where fluid can collect and can put undue stress on fittings. The support spacing depends on the tube diameter and operating temperature, with closer spacing required for larger tubes and higher temperatures.

Cost-Benefit Analysis: When to Choose PFA Over Other Materials

PFA tubing is a premium product with a corresponding price tag. It is significantly more expensive than PVC, polyethylene, or even stainless steel in many cases. Therefore, its use must be justified through a cost-benefit analysis. The initial purchase price is only one part of the total cost of ownership.

One should choose PFA when the cost of failure is unacceptably high.

- In a semiconductor fab, a single contamination event can ruin a batch of wafers worth hundreds of thousands of dollars. The incremental cost of UHP PFA tubing is negligible in comparison.

- In a pharmaceutical plant, product contamination can lead to batch rejection, regulatory fines, and patient safety issues. The reliability of PFA is a form of insurance.

- In an aggressive chemical plant, a leak can cause a safety hazard, environmental damage, and costly downtime for repairs. The longevity of PFA in corrosive environments reduces maintenance costs and improves safety.

In these scenarios, PFA is not an expensive luxury; it is the most cost-effective solution when viewed over the entire lifecycle of the system. The decision to use PFA is a decision to prioritize purity, safety, and long-term reliability over short-term material cost savings.

Frequently Asked Questions About PFA Tubing

What is the main difference between PFA and PTFE tubing? The primary difference is melt processability. PFA is a true thermoplastic that can be melt-extruded and injection molded, resulting in smoother surfaces and the ability to create more complex shapes. PTFE is not melt-processable and must be formed through a sintering process. While both share a high service temperature of 260°C and excellent chemical resistance, PFA has superior mechanical properties at high temperatures, particularly better creep resistance.

Can PFA tubing be sterilized? Yes, PFA tubing is excellently suited for sterilization. It can be repeatedly sterilized using all common methods, including autoclaving (steam sterilization), ethylene oxide (EtO), gamma radiation, and E-beam. Its high service temperature of 260°C means it easily withstands typical autoclave cycles of 121-134°C without any degradation. Its chemical inertness also makes it compatible with chemical sterilants like hydrogen peroxide.

Is PFA tubing resistant to UV light? Yes, PFA tubing has outstanding resistance to ultraviolet (UV) radiation. Unlike many other plastics that become brittle and degrade with UV exposure, the strong carbon-fluorine bonds in PFA are not broken by UV energy. This makes it suitable for outdoor applications and for use in processes involving UV light, such as UV water purification systems or photochemical reactors.

What is the maximum operating pressure for PFA tubing? The maximum operating pressure of PFA tubing is dependent on three factors: the tube’s diameter, its wall thickness, and the operating temperature. Pressure ratings decrease significantly as temperature increases. For example, a 1/4 inch OD tube with a 0.040 inch wall might be rated for over 500 psi at room temperature, but that rating could drop to around 150 psi at 200°C. Always consult the manufacturer’s specific pressure-temperature charts for the exact tubing dimensions you are using.

How do you connect PFA tubing? PFA tubing can be connected using several methods. The most common are compression fittings, which use ferrules to grip the outside of the tube, and flare fittings, which provide a more secure seal by flaring the end of the tube. For the highest level of purity and leak integrity, PFA can be fusion welded using techniques like infrared (IR) or hot gas welding to create a permanent, seamless bond between the tube and a fitting.

Is PFA tubing safe for food contact? Yes, many grades of PFA tubing comply with food contact regulations, such as FDA 21 CFR 177.1550. Its chemical inertness and non-stick properties mean it will not impart any taste or odor to the food product, and its smooth surface is easy to clean. It is often used in food and beverage processing for transporting everything from viscous sauces to high-purity water and cleaning solutions.

Заключение

The inquiry into the nature of PFA tubing leads us through a fascinating intersection of molecular chemistry, materials science, and practical engineering. It is not merely a plastic tube but a highly specialized solution born from a specific need: to capture the extraordinary performance of PTFE in a form that is versatile and manufacturable. Its identity is defined by a subtle yet profound architectural choice at the molecular level—the introduction of a perfluoroalkoxy side chain—that unlocks the world of thermoplastic processing without making significant compromises on chemical inertness or thermal stability.

This allows PFA to serve in environments where lesser materials would falter. It provides a pure and unreactive conduit for the aggressive chemicals and sensitive biologics that drive our most advanced industries, from semiconductors to pharmaceuticals. It withstands temperatures that would melt or decompose other polymers, all while maintaining its mechanical integrity. It offers the design freedom to create complex, leak-proof systems that are fundamental to safety and reliability. While it represents a significant investment compared to commodity materials, its value is not measured in its initial cost, but in the cost of failure it prevents—the cost of a contaminated product, a failed process, or a hazardous leak. PFA tubing stands as a testament to the power of deliberate material design, providing a robust and elegant solution to some of modern engineering’s most demanding challenges.

Ссылки

Entegris. (2025). FluoroLine® industrial grade PFA tubing. Retrieved from https://www.entegris.com/shop/en/JPY/products/fluid-management/fluid-handling/tubing-and-pipe/FluoroLine-Industrial-Grade-PFA-Tubing/p/FluoroLineIndustrialGradePFATubing

Fluorostore. (2025). PTFE, FEP, PFA, ETFE, ECTFE, PCTFE, and PVDF fluoropolymer material properties. Retrieved from

Gendian. (2025). Fluoropolymer tubing. Retrieved from https://www.gendianmaterials.com/extruded-tube/feppfa-tubing/

Gendian. (2025). FEP industrial fluoropolymer tubing. Retrieved from https://www.gendianmaterials.com/extruded-tube/fep-industrial-fluoropolymer-tubing/

Imbalzano, J. F., Kerbow, D. L., & Wheland, R. C. (1994). The art of fluoropolymer processing. Advanced Materials & Processes, 145(1), 27.

Quanda Plastic. (2022). PFA tube supplier | Specification chart, applications. Retrieved from

Scheirs, J. (Ed.). (2000). Modern fluoropolymers: High performance polymers for diverse applications. John Wiley & Sons.

Teng, H. (2012). Overview of the development of the fluoropolymer industry. Applied Sciences, 2(2), 496-512. https://doi.org/10.3390/app2020496

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn