Химическая стойкость труб пвдф

-

PVDF термоусадочная трубка OEM производитель

Термоусадочная трубка из ПВДФ Технические характеристики продукта:

Место происхождения: Китай

Фирменное наименование: Yozonetech

Тип: Изолятор

Материал: PVDF

Применение: Высокая температура

Номинальное напряжение: 1kv

Прочность на разрыв: 30 МПА мин

Название продукта: Термоусадочные трубки PVDF Термоусадочные трубки Kynar

Прочность на разрыв: 30 МПа мин

Рабочая температура:-55 ~ +150 °C

Удлинение при разрыве:150% мин

Удлинение при разрыве после старения: 100% мин

Воспламеняемость: легковоспламеняющийся

коэффициент усадки: 2:1

Способность поставки: 10000 метров/метров в день

Поливинилиденфторид (PVDF) - это тонкостенная термоусаживаемая трубка, изготовленная из радиационно-модифицированного поливинилиденфторида. Она прозрачна, огнестойка, устойчива к высоким температурам, большинству масел и химикатов, а также прочна и устойчива к порезам. Широко используется для защиты мест сварки, клемм и соединительных кабелей, подвергающихся воздействию высоких температур, промышленных топлив, растворителей и химических веществ.

Термоусадочная трубка из ПВДФ Особенности продукта:

Коэффициент усадки: 2:1

Минимальная температура усадки: ≥+135℃

Рабочая температура: от -55℃ до +150℃

Гибкий, коррозионностойкий, устойчивый к истиранию и порезам Экологический стандарт: RoHS

Стандартные цвета: Прозрачный, черный.

Производительность Производительность Индекс Метод испытания Физическая работоспособность Размер На заказ ASTM D 2671 Продольное изменение длины -10%~+5% ASTM D 2671 Прочность на разрыв ≥24,1 МПа ASTM D 2671 Удлинение при разрыве ≥300% ASTM D 2671 Коэффициент усадки ≤40% AMS-DTL-23053 Модуль тангенса ≥172 МПа ASTM D 2671 Плотность ≤1,9 г/см3 ASTM D 2671 Гибкость при низких температурах Без трещин AMS-DTL-23053(-55℃×4h) Термический шок Не капает, не течет, не трескается ASTM D 2671 (250℃×4 часа) Прочность на разрыв после термического старения ≥19,1 МПа ASTM D 2671 (225℃×168h) Удлинение при разрыве после термического старения ≥200% ASTM D 2671 (225℃×168h) Прозрачность СтабильностьИдентификация Маркировка остается четкой AMS-DTL-23053(200℃×24h) Характеристики электрической изоляции Диэлектрическая прочность ≥15,7 кВ/мм ASTM D 2671 Объемное сопротивление ≥1012Ω -см ASTM D 2671 Химические характеристики Коррозия меди Отсутствие коррозии ASTM D 2671 (160℃×16h) Огнестойкий Самозатухание в течение 60 секунд, степень горения бумажного флага UL224 VW-1

ASTM D 2671 C法Поглощение воды ≤0,5% ISO 846 B法, 23℃×24h Прочность на разрыв и устойчивость к грибкам ≥24,1 МПа ASTM D 2671 Удлинение при разрыве после устойчивости к грибку ≥300% ASTM D 2671 Диэлектрическая прочность и устойчивость к грибкам ≥15,7 кВ/мм ASTM D 2671 Прочность на разрыв после химической стойкости ≥13,8 МПа ASTM D 2671 Удлинение при разрыве после химической стойкости ≥200% ASTM D 2671 Диэлектрическая прочность после химической стойкости ≥15,7 кВ/мм ASTM D 2671

Размер ID продукта (мм) Размер после усадки (мм) Форма Упаковка м/рулон Дюйм мм ID Толщина стенки 1/32 Φ0.8 ≥0.8 ≤0.5 0.30±0. 10 Круглый 200 3/64 Φ1.2 ≥ 1.2 ≤0.6 0.33±0. 10 Круглый 200 1/ 16 Φ1.6 ≥ 1.6 ≤0.8 0.33±0. 10 Круглый 200 3/32 Φ2.4 ≥2.4 ≤ 1.2 0.33±0. 10 Круглый 200 1/8 Φ3.2 ≥3.2 ≤ 1.6 0.35±0. 10 Круглый 100 3/ 16 Φ4.8 ≥4.8 ≤2.4 0.35±0. 10 Круглый 100 1/4 Φ6.4 ≥6.4 ≤3.2 0.35±0. 10 Плоский 100 3/8 Φ9.5 ≥9.5 ≤4.8 0.38±0. 10 Плоский 50 1/2 Φ12.7 ≥ 12.7 ≤6.4 0.38±0. 10 Плоский 50 5/8 Φ15.0 ≥ 15.0 ≤7.5 0.40±0. 10 Плоский 50 3/4 Φ19. 1 ≥ 19. 1 ≤9.5 0.42±0. 10 Плоский 50 1 Φ25.4 ≥25.4 ≤ 12.7 0.42±0. 10 Плоский 50 1- 1/2 Φ38. 1 ≥38. 1 ≤ 19. 1 0.48±0. 10 Плоский 50

175ºC Термоусадочная трубка из ПВДФ

Введение продукта: Поливинилиденфторид 175℃ Термоусадочная трубка Изготавливается из радиационно-модифицированного поливинилиденфторида, обеспечивающего прозрачность, огнестойкость, устойчивость к высоким температурам, воздействию большинства масел и химических веществ, а также долговечность и стойкость к порезам. Термоусадочные трубки на заказ Находит широкое применение для защиты точек сварки, клемм и соединительных кабелей, которые Производители термоусадочных трубок подвергаются воздействию высоких температур, промышленных топлив, растворителей и химических веществ.

Термоусадочная трубка из ПВДФ Особенности продукта:

Коэффициент усадки: 2:1 Минимальная усадка

Температура: ≥+175℃

Рабочая температура: от -55℃ до +175℃

Гибкий, коррозионностойкий, устойчивый к истиранию и порезам

Экологический стандарт: RoHS

Стандартные цвета: Прозрачный, черный.

Производительность Индекс производительности Метод испытания Плотность 1,78 г/см³ ASTM D791 Прочность на разрыв ≥30 МПа ASTM D2671 Удлинение при разрыве ≥ 150% ASTM D2671 Удлинение при разрыве после старения ≥ 100% 250C×168h Объемное сопротивление ≥ 1014 Ω-см IEC 60093 Огнестойкий VW- 1 UL224 Гибкость при холодном изгибе Без трещин -55C×4h Термический шок Без трещин 250C×4h Коррозия меди Нет коррозии 180C×168h Стабилизация меди Стабилизация меди 180C×168h

Размер Размер изделия (мм) Размер после усадки (мм) Форма Упаковка м/рулон Дюйм мм ID Толщина стенки 3/64 Φ1.2 ≥ 1.2 ≤ 0.6 0.33±0. 10 Круглый 200 1/ 16 Φ1.6 ≥ 1.6 ≤ 0.8 0.33±0. 10 Круглый 200 3/32 Φ2.4 ≥ 2.4 ≤ 1.2 0.33±0. 10 Круглый 200 1/8 Φ3.2 ≥ 3.2 ≤ 1.6 0.35±0. 10 Круглый 100 3/ 16 Φ4.8 ≥ 4.8 ≤ 2.4 0.35±0. 10 Круглый 100 1/4 Φ6.4 ≥ 6.4 ≤ 3.2 0.35±0. 10 Плоский 100 3/8 Φ9.5 ≥ 9.5 ≤ 4.8 0.38±0. 10 Плоский 50 1/2 Φ12.7 ≥ 12.7 ≤ 6.4 0.38±0. 10 Плоский 50 5/8 Φ15.0 ≥ 15.0 ≤ 7.5 0.40±0. 10 Плоский 50 3/4 Φ19.1 ≥ 19.1 ≤ 9.5 0.42±0. 10 Плоский 50 1 Φ25.4 ≥ 25.4 ≤ 12.7 0.42±0. 10 Плоский 50 1- 1/2 Φ38.1 ≥ 38.1 ≤ 19.1 0.48±0. 10 Плоский 50 -

PVDF большого диаметра подгонянные трубки OEM производитель

Описание продукта: Трубка PVDF

1. Мы используем ПВДФ трубки (поливинилиденфторид) как идеальный материал для транспортировки сверхчистых жидкостей в фармацевтической и полупроводниковой промышленности благодаря присущей ему высокой чистоте, гладкой внутренней поверхности и чрезвычайно низкой проницаемости жидкости через его стенки.

2. Трубка PVDF широко используется в системах чистой воды и городской водоподготовки, преимуществами которой также являются устойчивость к сильным дезинфицирующим растворам и отсутствие добавок и вредных ионов металлов "экстрактивных".

3. Иногда инженерные приложения требуют фторопластовая трубка с отличной химической стойкостью, высокой чистотой и очень хорошими механическими свойствами, поэтому инженеры разработали ПВДФ. ПВДФ играет очень важную роль в химической футеровке или защитных барьерах.

4. ПВДФ превосходит другие фторполимеры по сопротивлению ползучести.

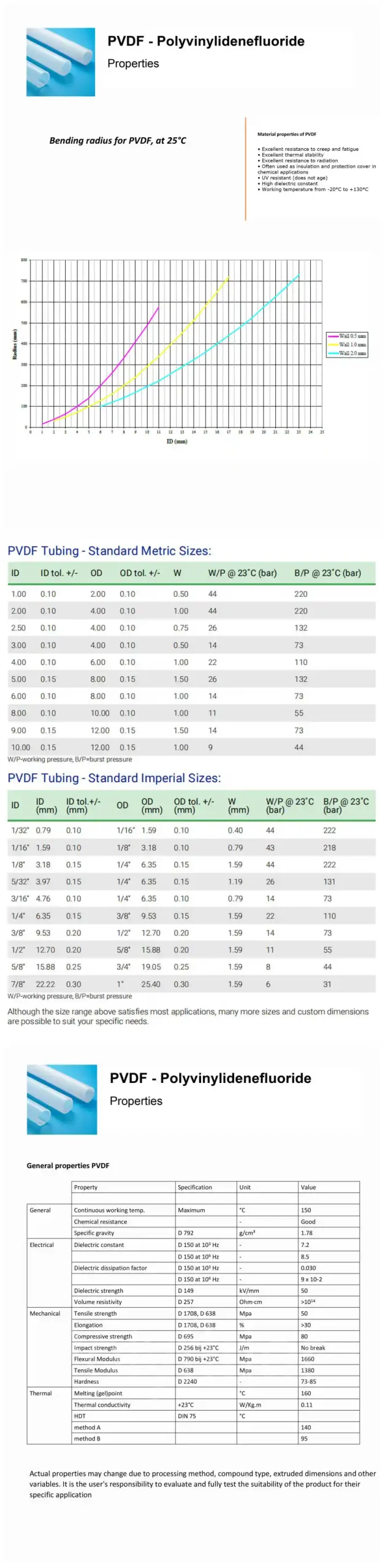

Трубки из ПВДФ Свойства материала

- Высокая диэлектрическая проницаемость

- Отличная термическая стабильность

- Устойчивость к ультрафиолетовому излучению (не стареет)

- Отличная устойчивость к радиации

- Отличная устойчивость к ползучести и усталости

- Рабочая температура от -20°C до +130°C

- Часто используется в качестве изоляции и защитного покрытия в химической промышленности

Трубки из ПВДФ Спецификация продукта:

Место происхождения: Китай

Фирменное наименование: YOZONE

Марка материала: Daikin chemical, DuPont. Dongyue & Chenguang (отечественные)

Длина: Подгонянный

Форма: Круглый

Цвет: черный, под заказ.

Рабочая температура: -20°C - +130°C

Допуск: ±0,05 мм

Химическая стойкость: стабилен в большинстве сред.

Электрические свойства: Устойчивость к изоляции

Сертификация: UL, CE, FDA, RoHS, REACH.

Стандарт: ISO9001:2008.

Испытание: SGS прошел

Образец: Бесплатно

Оплата: T/T

Экструдированная труба Срок службы: Зависит от окружающей среды, пожалуйста, проконсультируйтесь с нашими инженерами.

Экструдированная пластиковая трубка Применение: Нефтеперевозки, пищевая промышленность, электротехническая промышленность и т.д.

Трубки из ПВДФ Возможность поставки:

100000 метров в месяц Трубка PVDF

Трубки из ПВДФ Время выполнения:

Количество (килограммы) 1 - 10 11 - 50 51 - 100 >100 Оценка. Время (дни) 3 5 7 Предстоит согласовать

Трубки из ПВДФ Упаковка и доставка

Трубка PVDF в картонной коробке и деревянном поддоне

Порт: Тяньцзинь, Шанхай, Шэньчжэнь, Циндао.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn