ptfe tube fittings

-

PTFE Expanded O-ring Gasket Sheet

Ring Type Gasket Product Description

The PTFE o ring gasket seals we designed for shaft seals can withstand harsh environments, high temperatures, high pressures and long hours of work, which cannot be withstood by seals made of traditional elastic materials. Many of our PTFE compounds have been approved by the FDA.

Most of the polytetrafluoroethylene (PTFE) shaft seals produced by YOZONE are manufactured to meet the needs of various applications. PTFE tube are some standard sizes in the range of about 6 to 200 mm (0.250 to 8 inches) shaft diameter and about 16 to 230 mm (0.630 to 9 inches) inner diameter. For details of design and size, please contact YOZONE.

Main advantages of PTFE seals include:

- High chemical resistance

- Withstand speeds up to 30 m/s (5 900 ft/min)

- Wide operating temperature range, –70 to +250 °C (–95 to +480 °F)

- Withstand pressures up to 3,5 MPa (500 psi)

- Withstand dry running

Ring Type Gasket Product Specification

Place of Origin: China

Brand Name: YOZONE ptfe tube suppliers

Model Number: tsmcay-04

Pipe Material: 100% Virgin PTFE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: The same to drawing as client supplies

Color: White, transparent black, red, yellow and etc.

Density: 2.16 - 2.3g/cm³

Working Temperature: -180 - 240°C

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

Ring Type Gasket Supply Ability

10000 pieces per week Plastic PTFE seals and gasket

Ring Type Gasket Lead Time

Quantity(Kilograms)1 - 100 to >100

Est. Time(days) 7

To be negotiated

Ring Type Gasket Packaging & Delivery

Plastic PTFE extruded Lined Pipe Tube into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

-

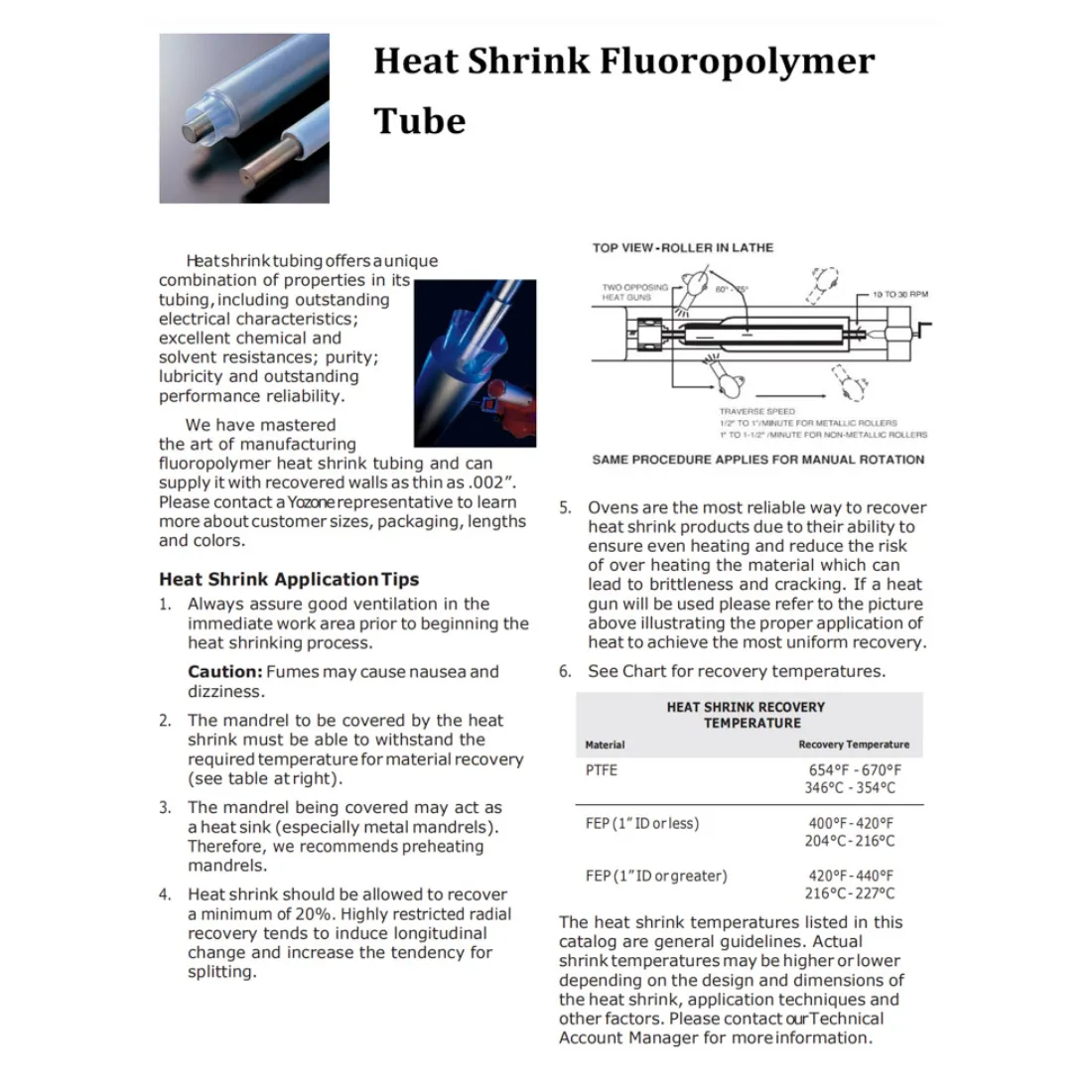

Customized PTFE Heat Shrink Tube Thin Wall Insulation Sleeve for Medical Catheter 4:1, 2:1 Ratio

PTFE Heat Shrink Tube Quick Details

Place of Origin: China

Brand Name: YOZONE

Pipe Material: 100% pure PTFE

Material brand: Daikin chemical, DuPont. Chemours, Dongyue(Domestic)

Specification: customized.

Length: Customized

Thickness: customized,

Shape: Round

Color: customized

Tolerance: ±0.05 mm

Tensile strength: 25Mpa (different specification are different)

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Heat shrink tubing manufacturers Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

PTFE Heat Shrink Tube Introduction

Yozonetech’s PTFE Heat Shrink Tubing is perfect for applications needing protection from harsh chemicals and extreme temperatures up to 260°C (500°F). Supplied in an expanded form, the high temp shrink tubing contracts to its original size when heated, creating a snug fit around the substrate. It's commonly used to safeguard sensors, rollers, and wire splicing, and is available in a range of standard custom heat shrink tubing sizes and configurations.

Highly resistant to aggressive chemicals

Highest use temperature of fluoropolymers: 260°C (500°F)

Melting Temperature: +320 °C

Excellent electrical insulation properties

Easily applied to a variety of substrates

Typical Applications

Automotive sensor protection

Wire insulation

Property ASTM Method Value Maximum Recommended Operating Temp. °C (°F) - +260 (500) Minimum Recommended Operating Temp. °C (°F) - -200 (-328) Shrink Temperature in °C (°F) - >320 (608) Hardness Shore D636 D50-D60 Tensile Strength in MPa (psi) D638 17-34 (2470-4930) Color - customized Ultimate elongation (%) D638 200-400 Specific Density g/cm³ D792 2,13 - 2,22 Water Vapor Transmission (g/m2.d.bar) D570 5 Dielectric Strength in kV/mm D149 15,7-19,7** Flammability UL94V0 Not flammable Thermal Conductivity at 25°C (77 °F) / C177 0.25 * Further colors on request.

** Thickness from 0,025 to 2,5 mm - value decreases with

increasing thickness.

Unless otherwise noted, all tests were conducted at room

temperature 23°C (73°F).

All values refer to special technical literature.

Additional sizes and colors are available upon request.

-

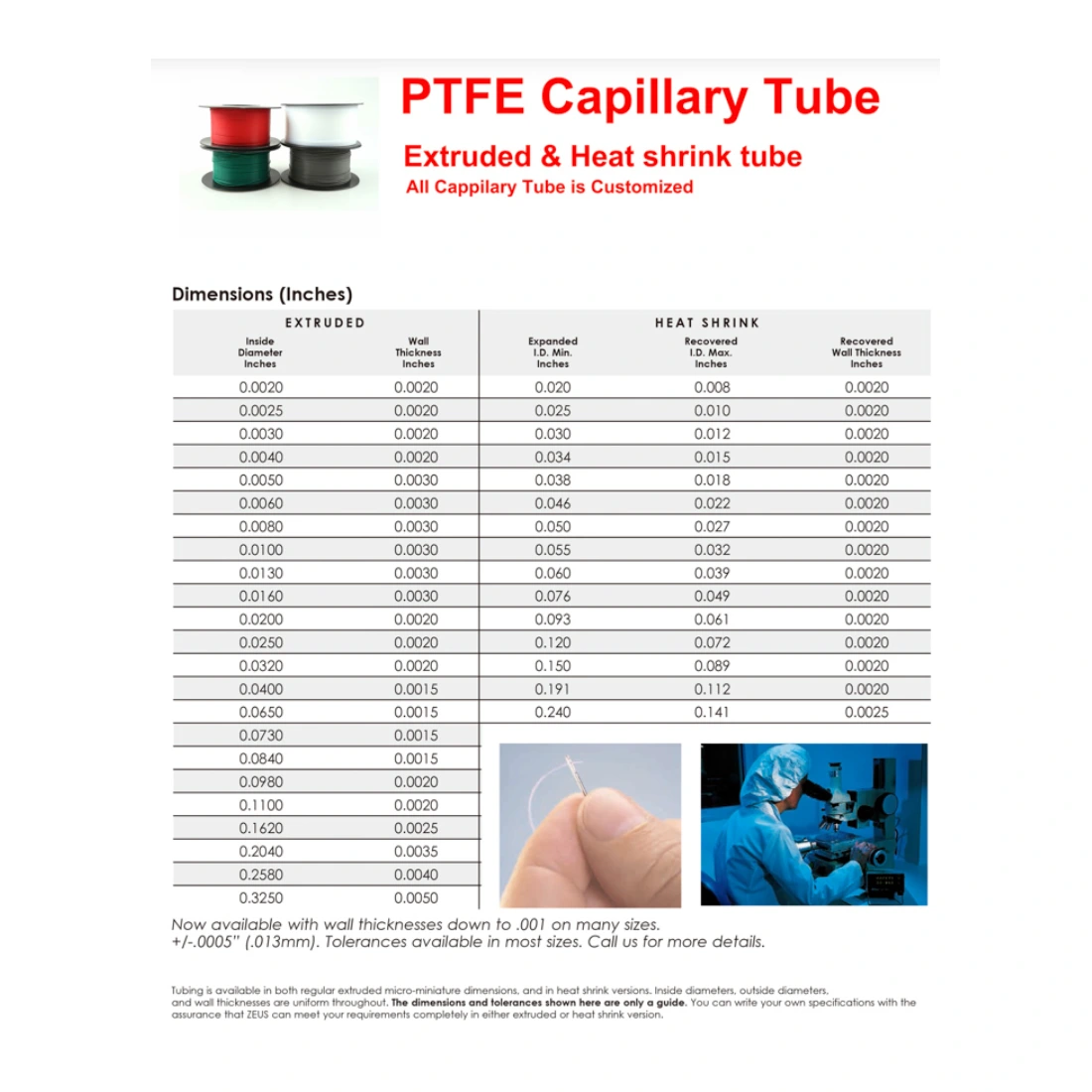

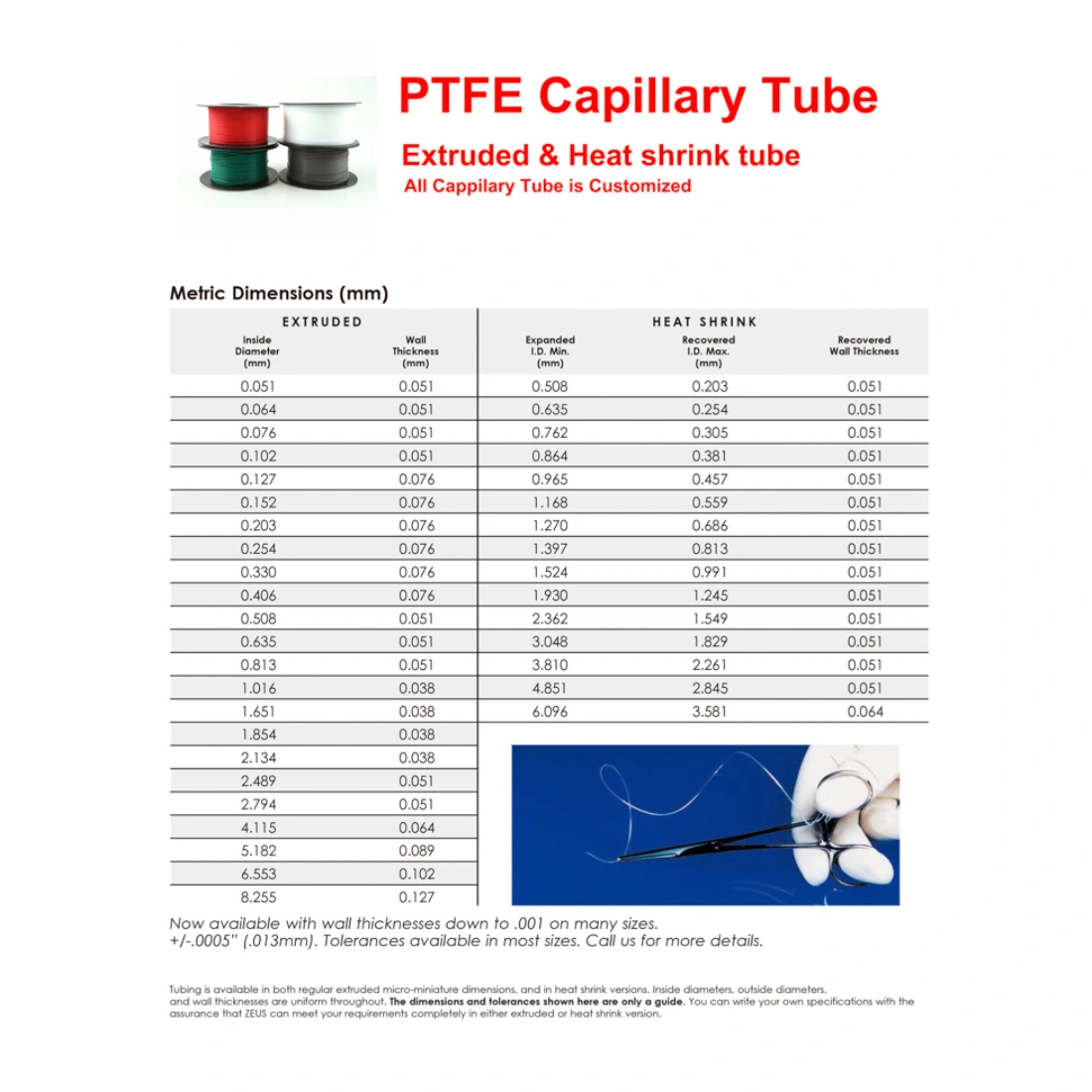

PTFE Capillary 0.05mm Thin-Wall Small Tubing OEM Manufacturer

Thin Wall PTFE Tubing Product Description

No.1 PTFE Capillary Molding Process

Polytetrafluoroethylene formaldehyde is a special tube made by mixing polytetrafluoroethylene dispersion resin with propellant, drying, sintering at high temperature, shaping, and bearing certain shearing force in a cone-angle die.

The capillaries of PTFE are extremely thin, and form a set of independent general specifications according to its use. Our minimum wall thickness can reach 0.02-0.05 mm. Of course, black, white, yellow, red and transparent baseballs can also be made according to different needs, generally in blue or black roll packaging.

No.2 The Main Features of PTFE Tube

1. Very low friction coefficient: The friction coefficient is generally only 0.04, which is a very good self-lubricating material, and the friction coefficient does not change with temperature.

2. High chemical stability: resistance to water, hydrofluoric acid, concentrated hydrochloric acid, nitric acid, fuming sulfuric acid, organic acid, strong alkali, strong oxidant, reducing agent, various organic solvents and other strong acids. Very suitable for high-purity chemical feeding.

3. Good anti-viscosity, the tube wall is not easy to block colloids and chemicals.

4. Excellent electrical insulation performance: PTFE is a highly non-polar material with good dielectric properties and high resistance. The dielectric constant is about 2.0, which is the smallest of all insulation products.

5. Flexible and collaborative.

6. Good resistance to viscosity, the tube wall is not easy to block colloids and chemicals.

7. Part of the tube is transparent for easy observation of the internal fluid state.

No.3 Use of PTFE Capillary

It is widely used in chemical industry, chlor-alkali industry, machinery, automobile, electric heating tube, pulp, steam, compressed gas, pipe, coating, textile, pharmaceutical, medicine, bicycle industry, coffee machine and other industries, mainly used in pipe.

In addition, you can also use polyperfluoroacetylene (polyvinyl formal and 6 f acrylonitrile) to complete the transparent wholesale ptfe tube extruder, which basically maintains the properties of PTFE, such as: excellent high temperature resistance and Low temperature, chemical stability, electrical insulation material, outstanding non-stick and high mechanical strength, only under the high temperature limit of 50 ℃ PTFE. But it is more flexible and transparent than PTFE, which makes it easier to see the internal situation when transporting liquids and gases.

Thin Wall PTFE Tubing Product Specification

Place of Origin: China

Brand Name: YOZONE

Model Number: tsmcay-02

Pipe Material: 100% Virgin PTFE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: customized.

Length: Customized

Thickness: Min. Wall Thickness 0.02 mm, customized,

Shape: Round

Color: White, transparent black, red, yellow and etc.

Density: 2.16 - 2.3g/cm³

Tolerance: ±0.05 mm

Tensile strength: 20Mpa (different specification are different)

Working Temperature: -60 - 240°C

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Extruded tube Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

Thin Wall PTFE Tubing Supply Ability

100000 Meters per Month Plastic PTFE Molded Lined Pipe Tube

Thin Wall PTFE Tubing Lead Time

Quantity(Kilograms) 1 - 10 11 - 50 51 - 100 >100 Est. Time(days) 3 5 7 To be negotiated

Thin Wall PTFE Tubing Packaging & Delivery

Plastic PTFE extruded Lined Pipe Tube into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

Yozonetech PTFE capillary has super-thin wall which is 0.025mm, and we can replace ZEUS INC to be your alternative supplier.

Yozonetech PTFE capillary tube will be packed on spool to protect.

Yozonetech PTFE capillary tube can be used in medical and food industry.

-

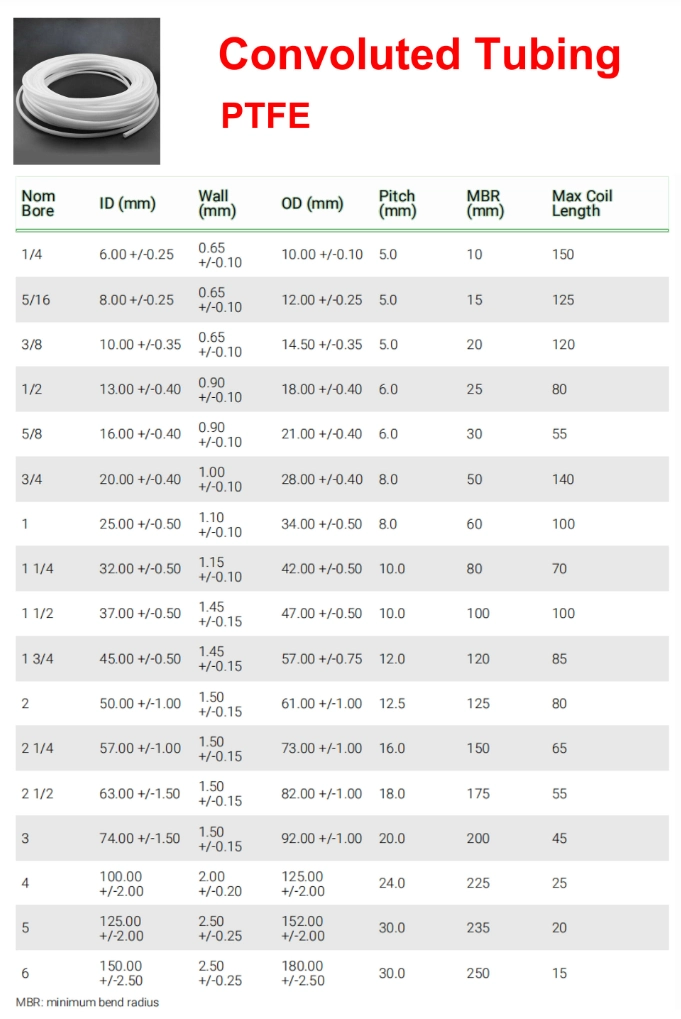

PTFE Flexible Extruded Convoluted Tubing OEM Manufacturer

PTFE Tubing Flexible Product Description:

1. Polytetrafluoroethylene (PTFE) convoluted tube is made of modified standard PTFE. Compared with most fluoropolymers, it has excellent bending life performance and greatly improves the resistance to stress cracking.

2. Compared with standard materials, the PTFE spiral tube has fewer pinholes and lower penetration, which makes it an excellent choice for the transmission of fine chemicals and highly searchable gases (such as chlorine) .

3. PTFE can be made into corrugated PTFE pipe, which has excellent flexibility. Anti-static design (black) or straight end (for connectors/accessories) are also available. In addition to PTFE, we also provide PFA, FEP and PVDF bellows.

We can also provide stainless steel braided corrugated PTFE tube, whose engineering strength will be greatly increased

Key properties of convoluted PTFE tubing:

• UV-resistant (does not age)

• Almost absolutely chemical inert

• FDA- approved (suitable for food industry)

• Applications from -50 up to 260°C

• No attachment (easily to clean)

• Vacuum lasting up to 90%

• Electric isolated (high dielectricity)

PTFE Tubing Flexible Product Specification:

Place of Origin: China

Brand Name: YOZONE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: DN6 - DN 150, customized.

Length: Customized

Shape: Round

Color: White, transparent black, red, yellow and etc.

Tolerance: ±0.05 mm

Tensile strength: 20Mpa (different specification are different)

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

PTFE Tubing Flexible Supply Ability:

2000 Meters per Month Plastic PTFE Convoluted Tube

PTFE Tubing Flexible Packaging & Delivery:

Plastic PTFE extruded Lined Pipe Tube into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

We are one of the professional manufacturers and ptfe tube supplier of custom tube in China, if you are interested in our custom 4mm ptfe tubing, custom 6mm ptfe tubing,custom ptfe extruded tube, high purity custom ptfe tubing made in China, please contact us immediately!

[embed]https://youtu.be/wFtLvm9Kzko[/embed]

Yozonetech PTFE convoluted and corrugated tube has excellent suppleness and its outer diameter can be larger or smaller than straight part.

-

PTFE Etching Tubing OEM Manufacturer for Medical

Medical Tubing Extrusion Product Description

PTFE often needs to be mixed with other materials, but due to its famous smooth surface, it is difficult to combine with other materials. The purpose of fluoropolymer etching is to change the surface characteristics of PTFE, after treatment, it can be combined with other materials, whether it is plastic, metal, composite material or ceramic.

The inherent bonding of fluoropolymers results in extremely low friction. In its unchanged state, the bonds of these polymers are so stable that it is difficult for them to bond with anything, even for a short period of time. When the etching process changes the carbon-fluorine bond of the PTFE bottom layer, the surface of the PTFE changes. After the PTFE is etched, its surface will have more friction, and it can be glued, molded or glued to other materials. It also allows the PTFE tube to be printed or engraved.

YOZONE-Technology provides the following key solutions for PTFE, FEP, PFA and PEEK products. So, today we will introduce you our quality Extruded Tube below:

PTFE tube supplier Extruded tubing is a versatile and widely used product in various industries. It is a continuous length of material that is formed by forcing it through a die, resulting in a hollow cylindrical shape.

-

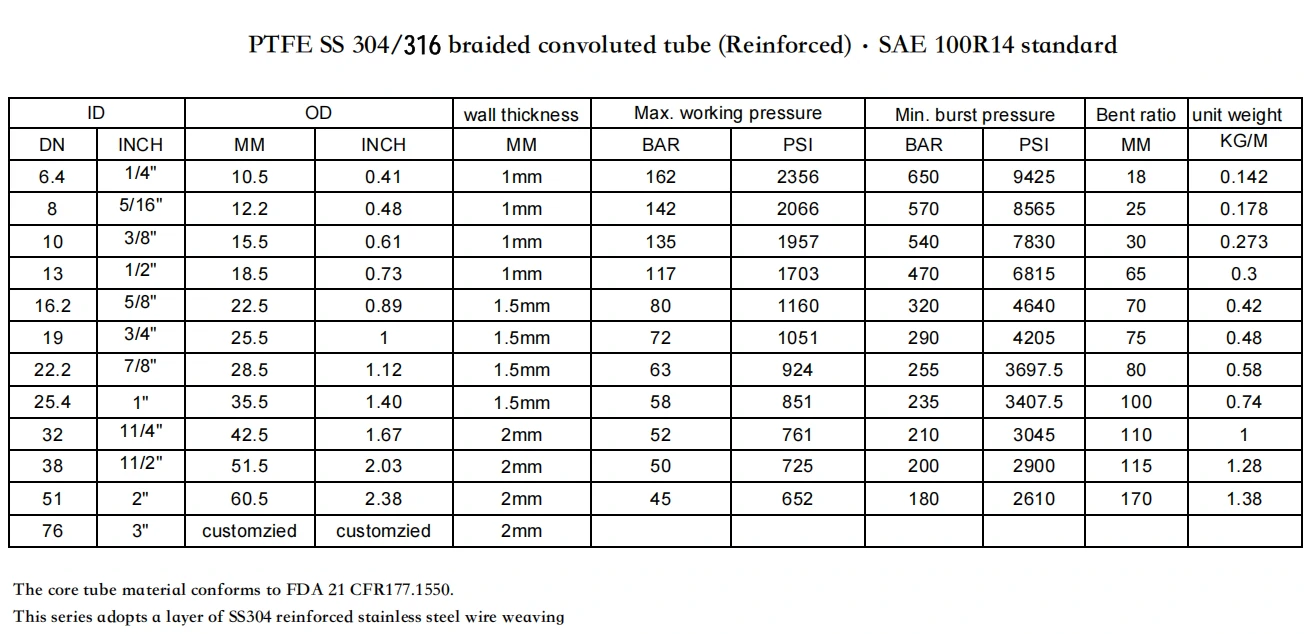

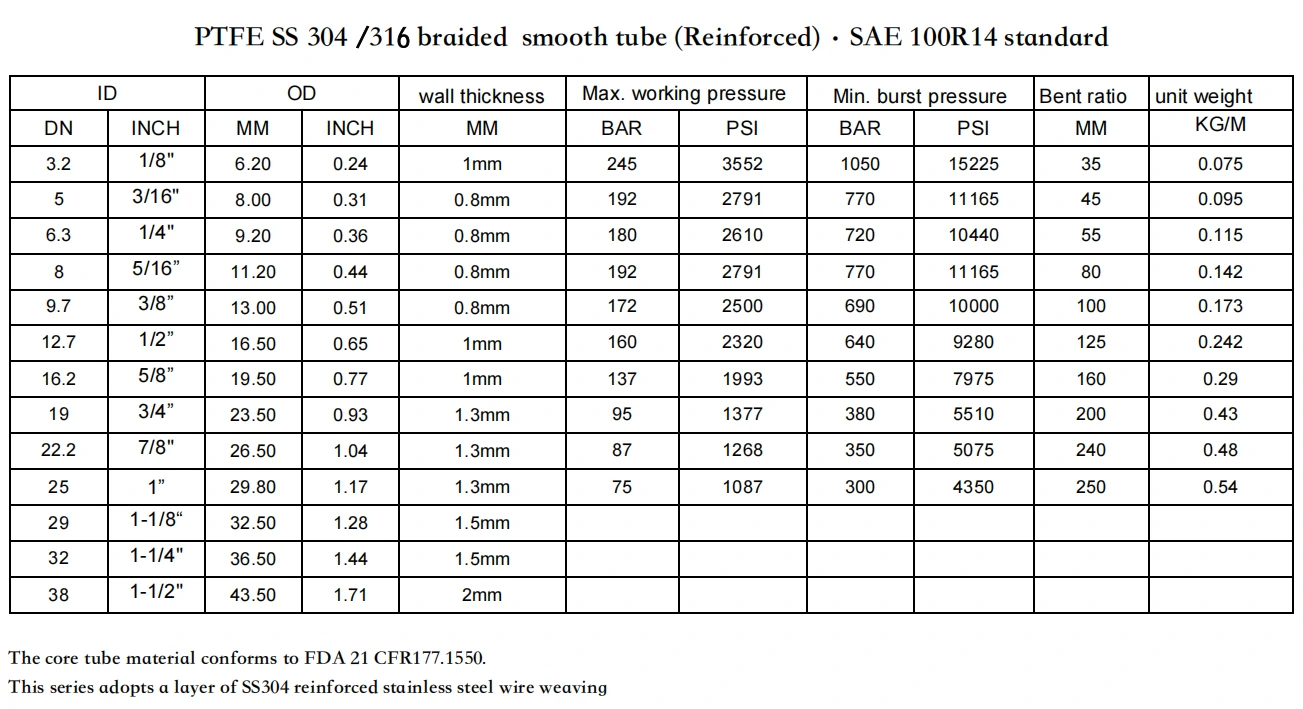

PTFE SS304/316 Braided Hose SAE100R14 for Industry and Food Grade

8mm PTFE tube Product Description:

1. Our 8mm PTFE tube product includes braided high-pressure tube, suitable for almost any demanding application. Because the stainless steel braided PTFE tube has super pressure resistance, extruded tube can be used in a variety of harsh working environments for a long time

2. The inner tube of this fluoroplastic high-pressure hose is made of modified PTFE, PTFE, ETFE or Zytel, and the outer layer is woven with stainless steel braids ranging from one to four layers. For applications requiring extreme working pressures, ptfe tube supplier can complete the hose with additional Kevlar coating.

3. The PTFE liner hose can provide straight or bellow design. Other fluoroplastic variants are available on request.

4. For protection or identification, our high-pressure PTFE tube are sometimes equipped with additional PVC shells or polyethylene/silicone.

Range of product:

• High pressure hose for oxygen

• High pressure hose for hydrogen-helium

• Super high pressure hose for gas applications

• High pressure hose for liquid including sulfuric acid and nitric acid

Product Specification:

Place of Origin: China

Brand Name: YOZONE

Model Number: tsmcay-07

Pipe Material: 100% Virgin PTFE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: customized.

Length: Customized

Shape: Round

Density: 2.16 - 2.3g/cm³

Tolerance: ±0.05 mm

Working Pressure: 127 KG

Burst Pressure: 382 KG

Working Temperature: -60 - 240°C

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

Supply Ability:

20 Tons per Month Plastic PTFE Stainless Steel Braided Tube

Lead Time:

Quantity(Kilograms)

1-10: 3 days

11-500: 7 days

501-1000: 15 days

1000+: negotiable

Packaging & Delivery

Plastic PTFE extruded Lined Pipe Tube into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn