PTFE Customized Flexible Extruded Smooth Bore Tubing OEM Manufacturer

Ptfe Flexible Tubing Product Description:

1. Polytetrafluoroethylene was first discovered in the 1930s by Dr. Roy Plunkett, a scientist at DuPont, and was first used in the top-secret Manhattan Project during World War II.

2. In the late 1940s, DuPont commercialized polytetrafluoroethylene (PTFE) under the name of PTFE. Extrudable grades of PTFE were later commercialized.

3 .As the polymer of choice for many advanced applications, polytetrafluoroethylene has many unique properties. Polytetrafluoroethylene has the lowest coefficient of friction of all polymers and a very wide operating temperature range, so it can be applied to various products from advanced medical equipment to high-temperature industrial equipment. Due to its incomparable chemical inertness, PTFE has become the plastic of choice in the chemical and analytical science industries.

4 .Our PTFE plastic can be made into various sizes of PTFE pipes (and modified PTFE). Smooth or curved (spiral or parallel), metric, imperial and AWG sizes. PTFE pipes can be made into straight pipes and packaged in coils or spools, and the cutting length can be customized. The natural color of PTFE tubing is milky white until slightly transparent. Other colors and pads are also available (in stock).

Ptfe Flexible TubingProduct Paramter

| Property | ASTM test | Value | |

| Physical properties |

Specific gravity | D792 | 2.15 |

| Water absorption ( % ) | D570 / 24 hrs 1/3" t | < 0.00 | |

| Mold shrinkage ( cm / cm ) | 0.02 - 0.05 | ||

| Contact angle ( degree ) | Angle to level | 110 | |

| Thermal properties |

Thermal conductivity | C177 | 6 x 10 - 4 (o /cm ) |

| thermal expansion Coefficient | D696 / 23 - 60oC | 10 x 10 - 5 (1/oC) | |

| Melting point (oC ) | 327 | ||

| Melt viscosity ( poise ) | 1011 - 1013 | ||

| Melt viscosity ( poise ) | (340 -380oC) | ||

| Max continues temperature | 260 / 500 (oC/F ) | ||

| Mechanical properties |

Tensile strength ( kgf / cm2 ) | D638 / 23oC | 140 - 350 |

| Elongation ( % ) | D638 / 23oC | 200 - 400 | |

| Compression strength | D695 / 1 % deformation, 25oC | 50 - 60( kgf / cm2) | |

| Tensile modulus ( kgf / cm2 ) | D638 / 23oC | 4,000 | |

| Flexural modulus ( kgf / cm2 ) | D790 / 23oC | 5,000 - 6,000 | |

| Impact strength ( ft - lb / in ) | D256 / 23oC, Izod | 3 | |

| Hardness (Shore) | Durometer | D50 - D65 | |

| Deformation under load ( % ) | D621 / 100oC , 70 kgf / cm2, 24 hrs | 5 | |

| D621 / 25oC , 140 kgf / cm2, 24 hrs | 7 | ||

| Static friction coefficient | Coated - steel surface | 0.02 | |

| Electrical properties |

Dielectric constant | D150 / 103Hz | 2.1 |

| D150 / 106 Hz | 2.1 | ||

| Dielectric dissipation factor | D150 / 103 Hz | < 1 x 10 - 5 | |

| Dielectric break down strength | D149 / Short time,1/ 8 in | 480 ( V / mil ) | |

| Volume resistivity( ohm - cm ) | D257 | > 1018 | |

| Chemical resistance | Excellent | ||

| Weather ability | Excellent | ||

| Combustibility ( % ) | D2863 / Oxygen concentration index | > 95 | |

PTFE Tubing Key Features

- Heat-resistant (-200°C to +260°C)

- Chemically inert (resists acids/alkalis)

- Non-stick & low friction

- Electrically insulating

- Flexible & crack-resistant

- Precision sizes (0.3-100mm)

- High Purity: No leaching, compliant with medical and food-grade standards (FDA/USP Class VI, UL, RoHS, REACH, CE, Biocompatibility, ISO9001 certified)

Full Process Quality Control System

Air pressure detection

Our ptfe tube manufacturers uses fully automatic imported sensor air pressure testing equipment. All PTFE tubes are tested with 8 kg air pressure inside and the pressure is maintained for 60 seconds to prevent all gas leaks.

Strong light impurity detection

The detection light source is composed of various monochromatic light sources and composite light sources to check various impurities such as black impurities and paraffin that are not easy to find in the production process of PTFE inner tubes.

Laser diameter controller

It can continuously and accurately control the inner and outer diameters and tolerances throughout the PTFE tube production process

High temperature pulse test bench

Wholesale ptfe tube company is the first medium high temperature (+260°) pulse test bench in the industry, which can test the pulse frequency of polytetrafluoroethylene tubes at different medium temperatures.

Electrical breakdown test (SAE J30)

Test the insulation of PTFE tube

Sparkle test

Sparkle testing can more accurately detect the small leaks of PTFE tube

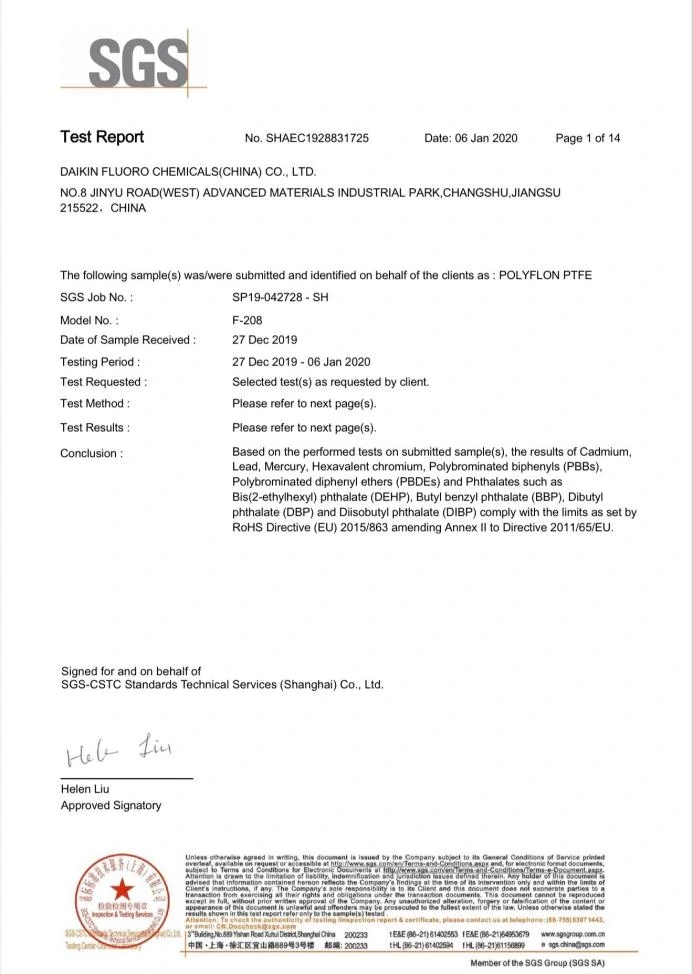

Certifications

PTFE tube FDA certificate

PTFE tube MSDS certificate

PTFE tube RoHS certificate

PTFE tube specifications

| size | ID(mm) | OD(mm) | Wall thickness(mm) |

Tolerance(mm) |

| 2*4 | 2 | 4 | 1 | ±0.1 |

| 4*6 | 4 | 6 | 1 | ±0.15 |

| 6*8 | 6 | 8 | 1 | ±0.15 |

| 8*10 | 8 | 10 | 1 | ±0.2 |

| 10*12 | 10 | 12 | 1 | ±0.2 |

| 12*14 | 12 | 14 | 1 | ±0.2 |

| 13*15 | 13 | 15 | 1 | ±0.2 |

| 14*16 | 14 | 16 | 1 | ±0.25 |

| 15*17 | 15 | 17 | 1 | ±0.2 |

| 16*18 | 16 | 18 | 1 | ±0.2 |

| 16*19 | 16 | 19 | 2 | ±0.3 |

| 18*20 | 18 | 20 | 1 | ±0.3 |

| 19*21 | 19 | 21 | 1 | ±0.3 |

| 19*22 | 19 | 22 | 2 | ±0.3 |

| 20*22 | 20 | 22 | 1 | ±0.3 |

| 22*24 | 22 | 24 | 1 | ±0.3 |

| 22*25 | 22 | 25 | 2 | ±0.3 |

| 23*25 | 23 | 25 | 1 | ±0.3 |

| 25*28 | 25 | 28 | 2 | ±0.3 |

| 25*29 | 25 | 29 | 2 | ±0.3 |

| 32*36 | 32 | 36 | 2 | ±0.5 |

| 38*42 | 38 | 42 | 2 | ±0.5 |

| 44*48 | 44 | 48 | 2 | ±0.5 |

| 47*51 | 47 | 51 | 2 | ±0.5 |

| 50*54 | 50 | 54 | 2 | ±0.5 |

| 51*55 | 51 | 55 | 2 | ±0.5 |

| 56*60 | 56 | 60 | 2 | ±0.5 |

| 74*82 | 74 | 82 | 4 | ±1.1 |

| 150*160 | 150 | 160 | 5 | ±2.1 |

PTFE capillary tube specifications

| AWG | ID | OD | PACKING | ||||

| Min | Normal | Max | S Model | T Model | L Model | ||

| 30 | 0.25 | 0.30 | 0.38 | 0.76 | 0.76 | 0.60 | 305 |

| 28 | 0.33 | 0.38 | 0.46 | 0.84 | 0.84 | 0.68 | 305 |

| 26 | 0.41 | 0.46 | 0.53 | 0.92 | 0.92 | 0.76 | 305 |

| 24 | 0.51 | 0.56 | 0.66 | 1.16 | 1.06 | 0.86 | 305 |

| 23 | 0.58 | 0.66 | 0.74 | 1.26 | 1.16 | 0.96 | 305 |

| 22 | 0.66 | 0.71 | 0.81 | 1.31 | 1.21 | 1.01 | 305 |

| 21 | 0.74 | 0.81 | 0.89 | 1.41 | 1.31 | 1.11 | 305 |

| 20 | 0.81 | 0.86 | 0.97 | 1.66 | 1.46 | 1.16 | 305 |

| 19 | 0.91 | 0.96 | 1.07 | 1.76 | 1.56 | 1.26 | 305 |

| 18 | 1.01 | 1.07 | 1.17 | 1.87 | 1.67 | 1.37 | 305 |

| 17 | 1.14 | 1.19 | 1.32 | 1.99 | 1.79 | 1.49 | 305 |

| 16 | 1.29 | 1.34 | 1.47 | 2.14 | 1.94 | 1.64 | 305 |

| 15 | 1.45 | 1.50 | 1.65 | 2.30 | 2.10 | 1.80 | 153 |

| 14 | 1.62 | 1.68 | 1.83 | 2.48 | 2.28 | 2.08 | 153 |

| 13 | 1.83 | 1.93 | 2.05 | 2.73 | 2.53 | 2.33 | 153 |

| 12 | 2.05 | 2.16 | 2.31 | 2.96 | 2.77 | 2.56 | 153 |

| 11 | 2.31 | 2.41 | 2.57 | 3.21 | 3.01 | 2.81 | 153 |

| 10 | 2.59 | 2.69 | 2.84 | 3.49 | 3.29 | 3.09 | 100 |

| 9 | 2.90 | 3.00 | 3.15 | 4.00 | 3.76 | 3.40 | 100 |

| 8 | 3.28 | 3.38 | 3.53 | 4.38 | 4.14 | 3.78 | 100 |

| 7 | 3.65 | 3.76 | 3.94 | 4.76 | 4.52 | 4.16 | 100 |

| 6 | 4.11 | 4.22 | 4.41 | 5.22 | 4.98 | 4.72 | 100 |

| 5 | 4.62 | 4.72 | 4.95 | 5.72 | 5.48 | 5.22 | 100 |

| 4 | 5.18 | 5.28 | 5.53 | 6.28 | 6.04 | 5.78 | 100 |

| 3 | 5.81 | 5.94 | 6.20 | 6.94 | 6.70 | 6.44 | 100 |

| 2 | 6.55 | 6.68 | 6.93 | 7.68 | 7.44 | 7.18 | 100 |

| 1 | 7.34 | 7.46 | 7.75 | 8.48 | 6.22 | 7.96 | 100 |

| 0 | 8.26 | 8.38 | 8.69 | 9.38 | 9.14 | 8.88 | 100 |

Why choose us

- Manufacturing Excellence

We are a direct manufacturer with over 50 production lines and a dedicated R&D team, ensuring precise control over quality and cost. Our OEM/ODM services allow full customization to meet your unique requirements. - Superior Material Options

We offer high-performance PTFE materials, including:

* Domestic brands (e.g., Dongyue) for cost-effective solutions.

* International brands (e.g., Daikin, Chemours) for demanding applications.

Our tubes withstand -200°C to +260°C and resist strong acids, alkalis, and solvents (e.g., sulfuric acid).3. Customization Flexibility

* Tailored inner/outer diameters, wall thickness, and lengths.

* Color options (white standard; black/transparent available with MOQ).4. Rapid Delivery & Stock Availability

* 3-5 working days for standard orders (most sizes in stock).

* Bulk/custom orders delivered with clear lead time communication.5. Quality Assurance

* Traceable raw materials and pre-shipment inspections (pressure tests, dimensional checks).

* Third-party reports (e.g., SGS) available upon request.6. Comprehensive Support

* Free samples (shipping costs may apply).

* Full customs clearance assistance with documents like COA, MSDS, and commercial invoices.7. Reliable After-Sales Service

* 24-hour response for quality issues, with replacements/refunds facilitated.8. Industry-Leading Properties

Our convoluted tubes excel in:

* Flexibility: Ideal for tight spaces and constant bending.

* Chemical/thermal resistance: Perfect for aerospace, chemical, and medical industries.

* Low friction: Reduces wear in dynamic applications.Choose us for unmatched expertise, quality, and service in PTFE convoluted tubing solutions. Contact our team today to discuss your project!

FAQ

Q: Are you a manufacturer?

A: Yes, we have our own R&D department and more than 50 production lines, and we provide OEM and ODM service.

Q: Do you offer free samples?

A: Yes, we provide free samples for testing. The quantity depends on specifications, but shipping costs may apply (or be paid upon delivery). Contact our sales team for sample availability.

Q: What is the delivery time?

A: We have most of sizes in stock and can them immediately, standard orders are delivered within 3-5 working days (from order confirmation). Custom sizes or bulk orders may require longer lead times, which we will communicate in advance.

Q: What material options are available?

A: We offer multiple PTFE material choices, including:

• Domestic high-quality brands: Such as Dongyue, cost-effective and compliant with local standards.

• International brands: Such as Daikin and Chemours, known for superior performance in demanding applications.

We can recommend the best material based on your needs.

Q: Do you assist with import customs clearance? What documents are provided?

A: Yes, we provide full customs clearance support, including:

- Certificate of Origin (C/O)

• Certificate of Analysis (COA)

• Material Safety Data Sheet (MSDS)

• Commercial invoice & packing list

• Customs declaration (if required)

Additional documents can be arranged upon request.

Q: What are the temperature and chemical resistance properties?

A: PTFE tubes can operate in -200°C to +260°C and resist strong acids, alkalis, and organic solvents (e.g., sulfuric acid,

hydrofluoric acid), making them ideal for chemical, semiconductor, and harsh environments.

Q: Can you customize sizes and colors?

A: Yes! We customize inner/outer diameters, wall thickness, and length. Standard color is white; other colors (e.g., black,

transparent) require a minimum order quantity (MOQ).

Q: How do you ensure product quality?

A: We guarantee quality through:

• Traceable raw materials.

• Pre-shipment inspections (dimensions, pressure tests, etc.).

• Third-party test reports (e.g., SGS) upon request.

Q: What payment methods are accepted?

A: We accept T/T (Bank Transfer), L/C (Letter of Credit), Alipay/WeChat Pay (for small orders) and other terms.

Terms are confirmed in the contract.

Q: What if there are issues after delivery?

A: For quality concerns, please keep the original packaging and provide photos/videos. We will respond within 24 hours to

arrange returns, replacements, or compensation.

----------------------------------------------------------------------------------------------------------------------------------

For further inquiries, contact our sales team!

Tel/WhatsApp/Wechat: +86 13752771911

Email: ptfetube@yozonetech.cn

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn