News

-

7 Data-Backed Distinctions — HDPE vs. PTFE: Material Differences and Comparisons

Read moreAbstract This document provides a comprehensive analysis of High-Density Polyethylene (HDPE) and Polytetrafluoroethylene (PTFE), two polymers with profoundly different characteristics and applications. It explores the foundational distinctions stemming from their molecular structures—the simple hydrocarbon chains of HDPE versus the fluorine-sheathed carbon backbone of PTFE. This structural variance dictates their performance across several domains. The investigation […]

-

An Expert’s 3-Point Breakdown: PTFE vs Teflon – Is there any real difference between them?

Read moreAbstract The discourse surrounding polytetrafluoroethylene (PTFE) and Teflon often leads to confusion, with many perceiving them as distinct materials. This examination clarifies that Teflon is not a separate substance but a registered trademark, originally by DuPont and now owned by Chemours, for its brand of PTFE and other fluoropolymers. The fundamental identity of the material […]

-

HDPE vs. PTFE: Material Differences and Comparisons

Read moreHDPE vs. PTFE: Understanding the Fundamentals In the diverse world of high-performance polymers, High-Density Polyethylene (HDPE) and Polytetrafluoroethylene (PTFE) represent two of the most widely used materials, yet they serve vastly different industrial roles. To truly understand hdpe vs teflon, one must first acknowledge that they are both thermoplastics but exist at opposite ends of […]

-

What is better, PVC or PTFE? An Expert Breakdown for 5 Critical Applications in 2026

Read moreAbstract The selection between Polyvinyl Chloride (PVC) and Polytetrafluoroethylene (PTFE) for industrial and commercial applications represents a critical decision point for engineers, designers, and procurement specialists. This analysis examines the fundamental structural, chemical, thermal, and mechanical properties of both polymers to provide a comprehensive framework for determining their suitability across various contexts. PVC, a versatile […]

-

The Expert’s Answer: Is Teflon Tubing the Same as PTFE? A 2025 Guide to 3 Key Fluoropolymers

Read moreAbstract This document examines the relationship between Teflon and Polytetrafluoroethylene (PTFE), clarifying that Teflon is the registered trademark for PTFE, a synthetic fluoropolymer of tetrafluoroethylene. The analysis extends beyond this initial clarification to provide a detailed comparative study of PTFE against other key fluoropolymers, namely Fluorinated Ethylene Propylene (FEP) and Perfluoroalkoxy Alkane (PFA). It investigates […]

-

Expert Guide 2025: What Does PTFE Stand For & 7 Critical Industrial Applications

Read moreAbstract Polytetrafluoroethylene, commonly abbreviated as PTFE, is a synthetic fluoropolymer of tetrafluoroethylene. Its discovery and subsequent commercialization represent a significant milestone in materials science, offering a substance with an extraordinary combination of properties not found in other materials. This high-performance polymer is characterized by its profound chemical inertness, rendering it resistant to a vast array […]

-

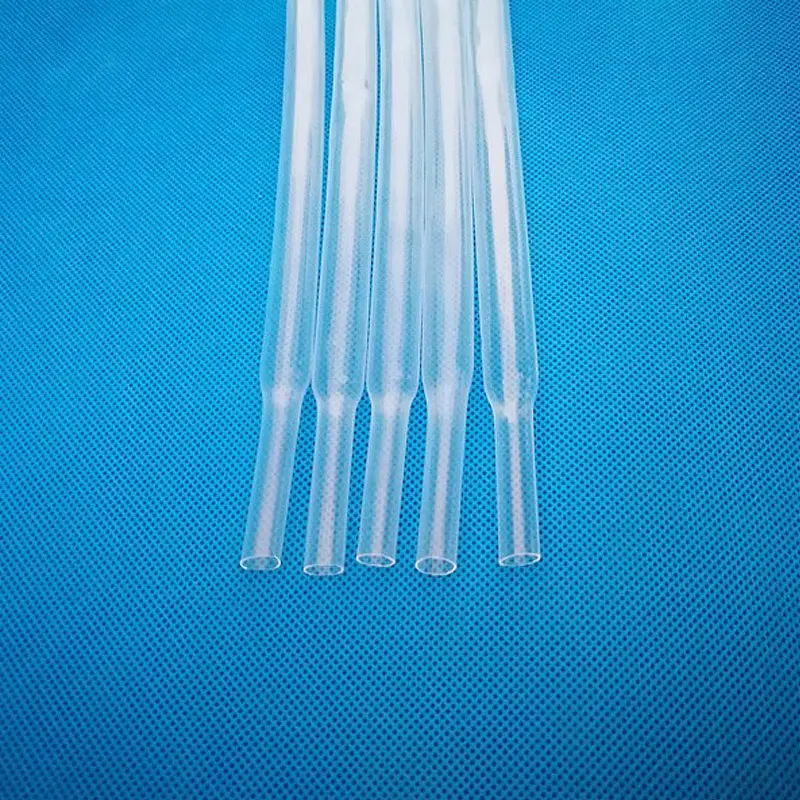

What Is FEP Heat Shrink Tubing? Properties, Manufacturing Process, and Industrial Applications

Read moreFEP heat shrink tubing has become one of the most important protective materials across electronics, medical devices, and industrial equipment. But many buyers still ask: What exactly is FEP heat shrink tubing, and how does it work? If you are new to this product, heat shrink tubing suppliers guide gives you a complete and technical explanation—from its […]

-

How to Choose the Right FEP Heat Shrink Tubing: Engineering Parameters That Actually Matter

Read moreFEP heat shrink tubing is widely used in semiconductor equipment, medical devices, analytical instruments, automotive sensors, and high-purity fluid handling systems. Yet many engineers and procurement teams struggle to choose the correct tubing specifications because the shrink behavior, tolerance, and thermal stability of FEP differ greatly from other fluoropolymers. Selecting the wrong shrink ratio or […]

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn