heat shrink plastic tubing

-

FEP Peelable Heat Shrink Medical Grade Tube with Bio-Compatibility Certification

Medical heat shrink tubing Performance and usage:

Polyper fluoroethylene propylene FEP medical peelable heat shrink tubing has excellent electrical insulation properties and high temperature resistance, and is used in

Components that need to be exposed to high temperature environments and have high insulation requirements during the process. Has excellent resistance to liquids and

Corrosive, physiologically inert, can be in direct contact with human skin, mainly used in surgical medical instruments and medical components and equipment.

Medical heat shrink tubing Features:

Shrink ratio: 1.3:1

Working temperature: -55℃~200℃

Initial shrinkage temperature: ≥150℃

good transparency

Excellent electrical insulation properties and physiological inertness

Meets ethylene oxide (ETO), gamma sterilization

Heat shrink tubing manufacturers Compliant with ISO 10993-1

Custom heat shrink tubing Environmental standards: no heavy metals, ROHS compliant

Standard color: transparent

Medical heat shrink tubing Specification

No.

Size

ID before shrinking(mm)

ID after shrinking(mm)

Wall after shrinking(mm)

1

XMC-FEP φ1.2mm

>1.20

<0.70

0.20±0.05

2

XMC-FEP φ2.5mm

>2.50

<1.80

0.20±0.05

3

XMC-FEP φ2.8mm

>2.80

<2.10

0.25±0.05

4

XMC-FEP φ3.1mm

>3.10

<2.20

0.25±0.05

5

XMC-FEP φ4.7mm

>4.70

<2.90

0.25±0.05

Medical heat shrink tubing Technical indicators

Item

Test method

Typical data

Tensile strength(Mpa)

ASTM D 638

≥13.8Mpa

Elongation at break

ASTM D 638

≥300%

Axial shrinkage change rate

ASTM D 2671

±10%

Dielectric strength (kV/mm)

ASTM D 2671

≥19.70

Insulation withstand voltage

ASTM D 149

4000V, no breakdown in 60s

Volume resistivity

UL 224

≥101*Ω.cm

Low temperature flexibility

AMS-DTL-23053

65℃/4 hours, no cracks

Copper corrosion

AMS-DTL-23053

No dents or blackening

clarity stability

AMS-DTL-23053

pass

Flame retardancy

ASTM D 2671C法

Self-extinguishing within 15s

-

PTFE/FEP Dual Wall Heat Shrink Tubing Customized OEM Manufacturer

Thick wall heat shrink tubing Product Description

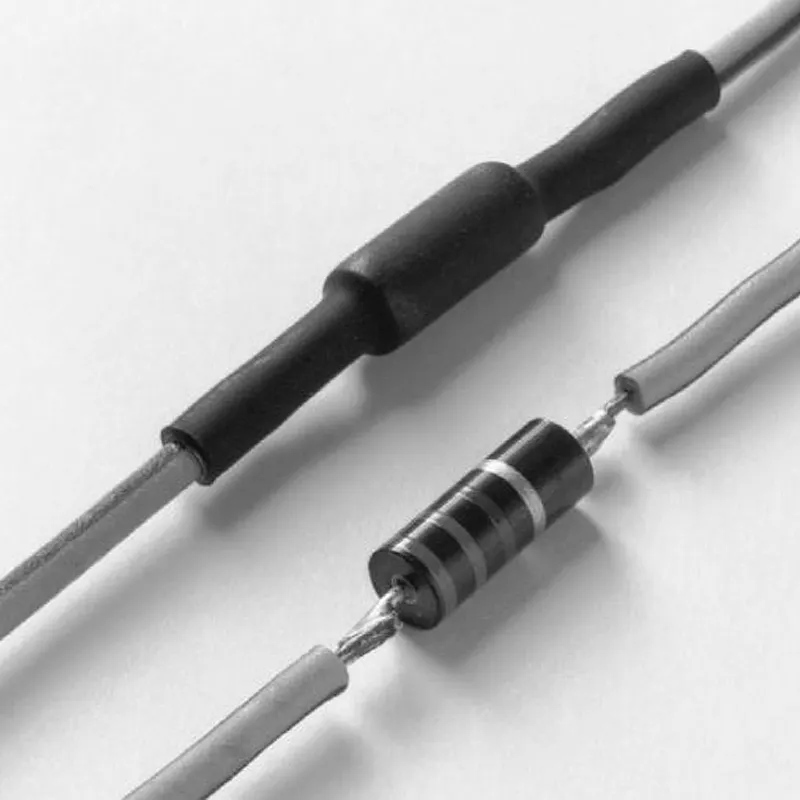

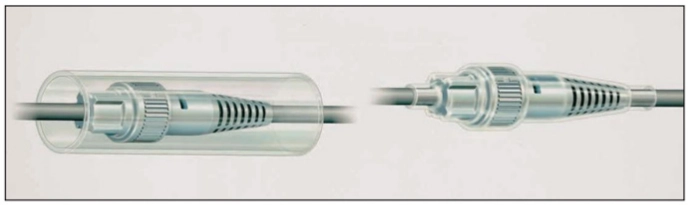

The double-wall heat shrinkable tube is mainly used to protect the components from corrosive gas and liquid from outside. The double-wall heat shrinkable design includes an outer layer of PTFE tube, and then a fusible FEP tube lining. The melting point of FEP is much lower than the shrinking temperature of PTFE, so when heated, FEP will melt and cover the components first, and then the PTFE tube will shrink and wrap the FEP. After cooling treatment, FEP solidifies and tightly combines with PTFE and components to form a tight protective layer to seal the entrance. The maximum operating temperature of the packaged components is approximately 210°C (410°F).

[embed]https://youtu.be/-hgILz2qbT4[/embed]

[embed]https://youtu.be/Z_qx0oQW3R8[/embed]

Thick wall heat shrink tubing Application

The application range of double-wall heat shrinkable tubing includes wire and cable harnesses, connectors, joints and any electrical terminals that may need to be protected from damage by moisture or corrosive liquids.

Thick wall heat shrink tubing Product Specification

Place of Origin: China

Brand Name: YOZONE

Model Number: tsmcay-11

Pipe Material: 100% Virgin PTFE & FEP

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: customized.

Length: Customized

Thickness: customized,

Shape: Round

Color: Transparent or Black (Designed for hiding the detail of product)

Tolerance: ±0.05 mm

Tensile strength: 10.4Mpa (different specification are different)

Working Temperature: -200 - 205°C

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

Thick wall heat shrink tubing Supply Ability

20000 Rolls per Month Plastic PTFE Dual Wall heat shrinking tube

Thick wall heat shrink tubing Lead Time

Quantity(Kilograms) 1 - 10 11 - 50 51 - 100 >100 Est. Time(days) 3 5 7 To be negotiated

Thick wall heat shrink tubing Packaging & Delivery

Plastic PTFE Dual Wall Heat Shrink Tube into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

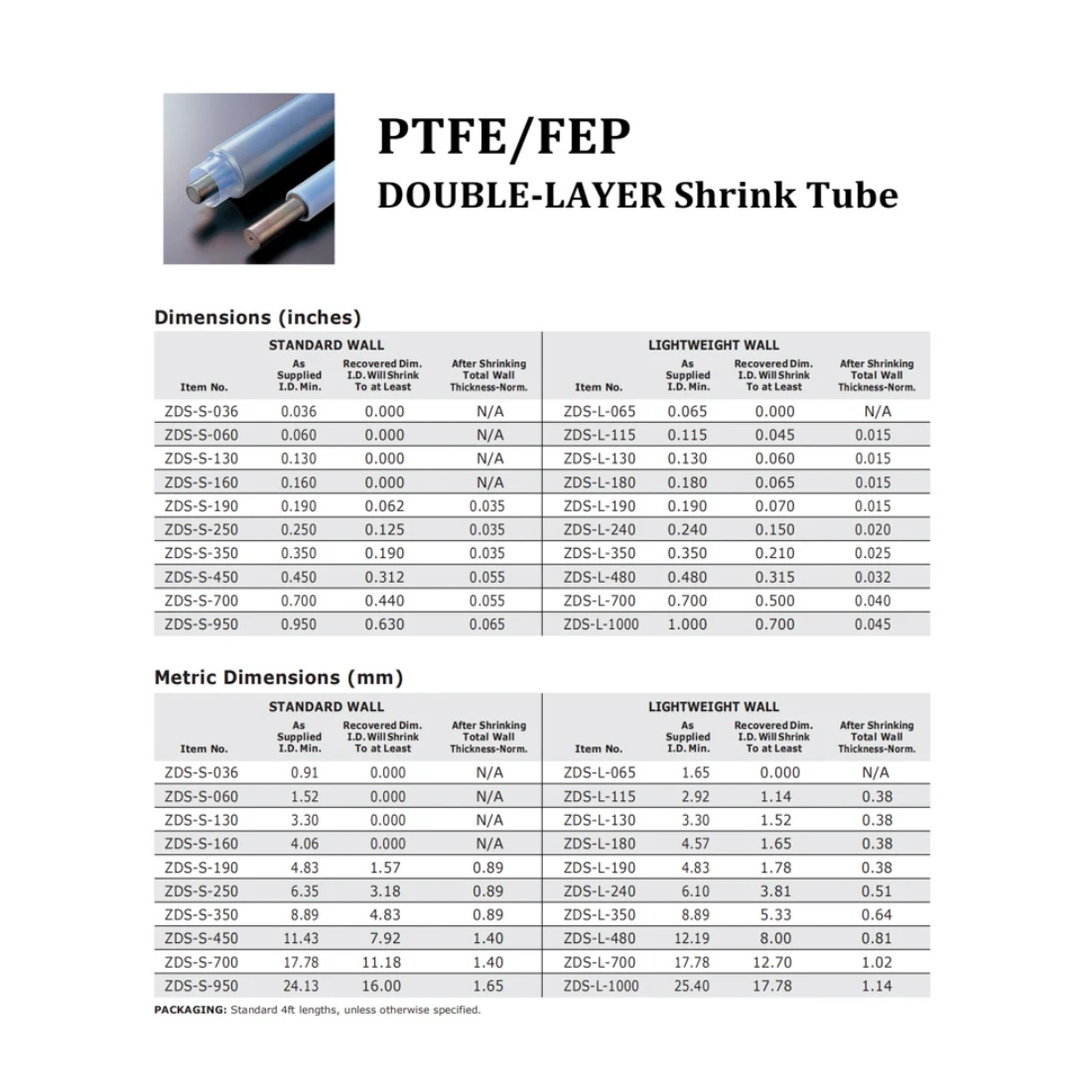

PTFE/FEP DOUBLE-LAYER Shrink Tube:

Heat Shrink Tubing Offering a Tight,

Moisture-Resistant, Wear-Proof Encapsulation

Outer tubing of PTFE shrinks for tight fit when heat is applied.

Inner layer of FEP melts and flows to encapsulate parts.

PTFE/FEP heat shrink tube is constructed with an exterior of heat shrink PTFE and an inner layer of FEP. It is easy to apply, and is designed to provide a tight, moisture-proof bond over wires, cables, connectors, splices, terminals, etc.

The PTFE shrinks tightly over inserted parts when the covered section is heated, while the FEP melts and flows into a solid or near-solid encapsulation with a fit so tight that it can withstand the most severe stresses involving pull or vibration. We provides all the outstanding electrical, chemical, and mechanical properties of PTFE including a service temperature up to 450°F/232°C. Custom specifications and tolerances quoted upon request.

We are one of the professional heat shrink tubing suppliers and manufacturers of fep heat shrink tubing in China, if you are interested in our fep tubing, chemfluor fep tubing, fep corrugated tubing, high purity pfa tubing made in China, please contact us immediately!

-

PTFE Heat Shrinking Tube

YOZONE can provide you PTFE precise machined part customized OEM, PTFE film customized OEM, PTFE molded sheet Plate and PTFE molded tube.

PTFE heat shrink tube is a type of tube that shrinks when heated. It is made from a fluoropolymer known for its non-stick properties and resistance to chemicals, heat, and electrical insulation.

What are the main uses of PTFE heat shrink tube?

PTFE heat shrink tubing is commonly used in:

1.Electrical insulation

2.Wire bundling

3.Chemical resistance applications

4.High-temperature environments

5.Aerospace and automotive industries

6.Medical devices

What is the difference between PTFE heat shrink tube and other types like PVC or polyolefin?

Feature PTFE Heat Shrink tube PVC Heat Shrink tube Polyolefin Heat Shrink tube Temperature Range Up to 260°C Up to 85°C Up to 125°C Chemical Resistance Excellent Moderate Good Electrical Insulation Excellent Good Good Flexibility Moderate High High Cost Higher Lower Moderate What is the temperature range of PTFE heat shrink tube?

PTFE heat shrink tube can withstand temperatures ranging from -200°C to +260°C.

How stable is PTFE heat shrink tube chemically?

PTFE heat shrink tube exhibits excellent chemical stability, being resistant to a wide range of acids, bases, and organic solvents. It does not react with most chemicals.

In which industries is PTFE heat shrink tube used?

PTFE heat shrink tube is utilized in various industries, including:

1.Aerospace

2.Automotive

3.Electronics

4.Medical

5.Chemical processing

6.Telecommunications

What are the specifications and size selection standards for PTFE heat shrink tube?

When selecting PTFE heat shrink tube, consider the following specifications:

1.Diameter: Choose based on the size of the wire or component it will cover.

2.Shrink Ratio: Common shrink ratios are 2:1 or 4:1.

3.Wall Thickness: Thicker walls offer better insulation and protection.

4.Length: Available in various lengths depending on application needs.

Example Table for Specifications

Specification Standard Options Diameter 1mm - 50mm Shrink Ratio 2:1, 4:1 Wall Thickness 0.1mm - 0.5mm Length 1m, 5m, 10m Why Choose us

At YOZONE, heat shrinkable tubing manufacturer take pride in our commitment to excellence and strive to exceed customer expectations. As a well-known dual wall heat shrink tubing suppliers factory, we are dedicated to providing reliable and durable products that meet the diverse needs of our valued customers. Trust YOZONE for all your rubber tube requirements.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn