rubber injection mold

-

Rubber Injection Molding Part

Rubber Injection Molding Product Specification

Place of Origin: China

Pipe Material: 100% pure Rubber

Length: Customized

Shape: customized according to drawing given by customers

Color: White, transparent black, red, yellow and etc.

Certification: UL, CE, FDA, RoHS, REACH, USP Class VI

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

Product Description

Molded rubber finds widespread applications across industries globally, serving essential roles in vibration isolation, rubber molding, extruded rubber, and rubber-to-metal bonding. The success or failure of standard operations often hinges on the performance of these small but critical rubber products, which are indispensable for vehicles and machinery.

Various specifications dictate the suitable molding process for different applications, ensuring cost-effective solutions and customized rubber products to meet specific needs. Key factors for determining the right fit include size, geometry, weight, material, and volume of parts required.

There are three main categories of rubber molding and application. First, let's examine these categories:

1. Rubber Transfer Molding: Ideal for parts with complex designs or multiple cavities, requiring a closed mold for rubber bonding to metal parts. This process is particularly important for air-free mold cavities.

2. Rubber Compression Molding: An original process utilized for low to medium production volumes, commonly used for seals, O-rings, gaskets, and bulkier parts. It works best for applications with specific production quantity and strong materials, though it may involve lengthy curing times and specific mold requirements.

3. Injection Molding: The most popular and versatile process, involving the use of nozzles and sprues to inject uncured rubber into molds. Different variations of injection molding are available, including organic rubber injection, liquid injection molding (LSR), and thermoplastic rubber injection (TPR).

These molding processes have diverse applications and provide standard solutions for many industries. However, when requirements go beyond standard applications, custom rubber injection molding offers made-to-order solutions that precisely meet unique specifications.

Custom Rubber Injection Molding provides a solution for businesses and manufacturers with unique part needs, allowing them to achieve cost-efficient and highly effective innovations. RPM Industrial Rubber Parts is a trusted company with over 50 years of experience, offering comprehensive A-Z service for custom rubber parts, silicone rubber components, extrusion, and bonding. With a focus on optimal solutions, RPM Industrial Rubber Parts can help design and create custom engineer plastic products that perfectly match the specific needs of clients. The injection molding supplier ensures a seamless 3-step process, from defining the required part and design to prototyping, production, and prompt shipping, providing clients with top-quality custom rubber parts and exceptional service.

-

Viton Injection Molding Part

Viton Injection Molding Product Description

The application of Viton materials under extreme conditions may be difficult to develop due to high costs. It has low toughness and limited tear strength unless some compounding steps are taken to improve it. But he has good impact resistance. In addition, Viton injection molding has excellent heat resistance and oil resistance, so it can be used for thermal grease in engines and compressors, and with its excellent corrosion resistance, engineer plastic products has strong applicability in a variety of concentrated acids.

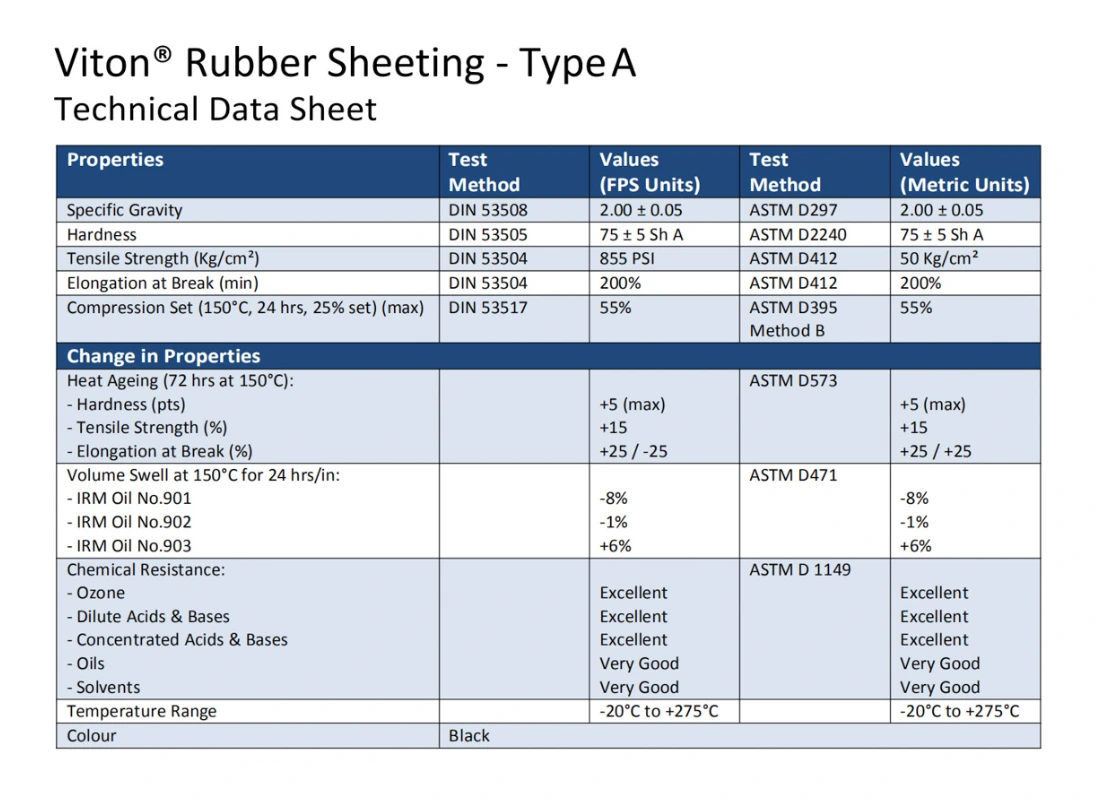

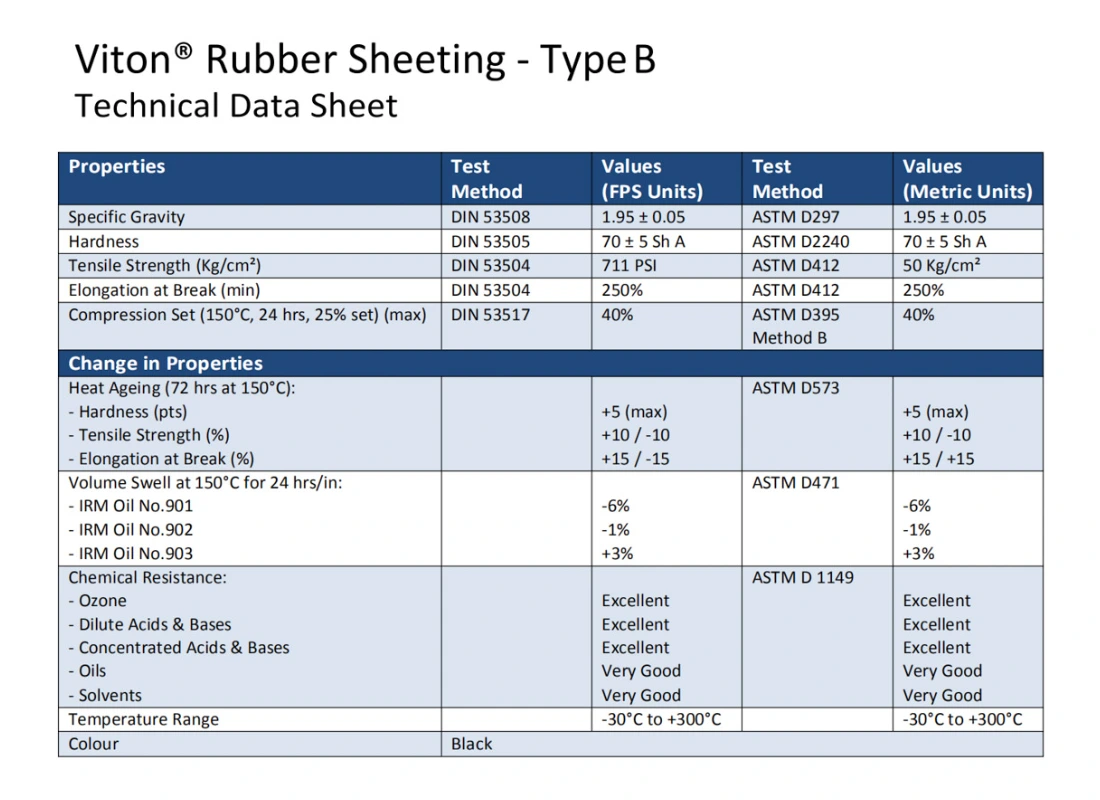

Viton Injection Molding Product Specification

Polymer: Hexaflouropropylene Vinylidene Flouride

ISO/ASTM Desgination: FKM

Durometer Rating (hardness): 75 (Shore A)

Temperature Range: -18°F to +400°F

Elongation: 200%

Tensile Strength: 1000 PSI

Finish: Plate, Fabric, Smooth Paper

Width: 36"

Gauge (thickness): 1/32", 1/16", 3/32", 1/8", 3/16", 1/4"

Pressure Sensitive Adhesive (PSA): Yes

Grades: Commercial, Viton A, Viton B, Viton F, Viton Extreme

Additional Viton Gasket Material Available: Yes

Place of Origin: China

Brand Name: YOZONE rubber injection molding manufacturer

Model Number: tsmcay-34

Pipe Material: 100% Virgin Viton

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: Customized.

Length: Customized

Thickness: customized,

Shape: Round

Color: Black, customized

Working Temperature: -26-232°C (275°C in short time)

Tolerance: ±0.05 mm

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Aerospace and electrical

Viton Injection Molding Supply Ability:

100000 Pcs per Month Viton Seals and Gaskets

Viton Injection Molding Lead Time:

Quantity(Kilograms) 1 - 10 11 - 50 51 - 100 >100 Est. Time(days) 3 5 7 To be negotiated

Viton Injection Molding Packaging & Delivery

Viton Seals and Gaskets into Carton and Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

-

Nitrile (NBR) Injection Molding Part

Injection molding nitrile rubber Product Description

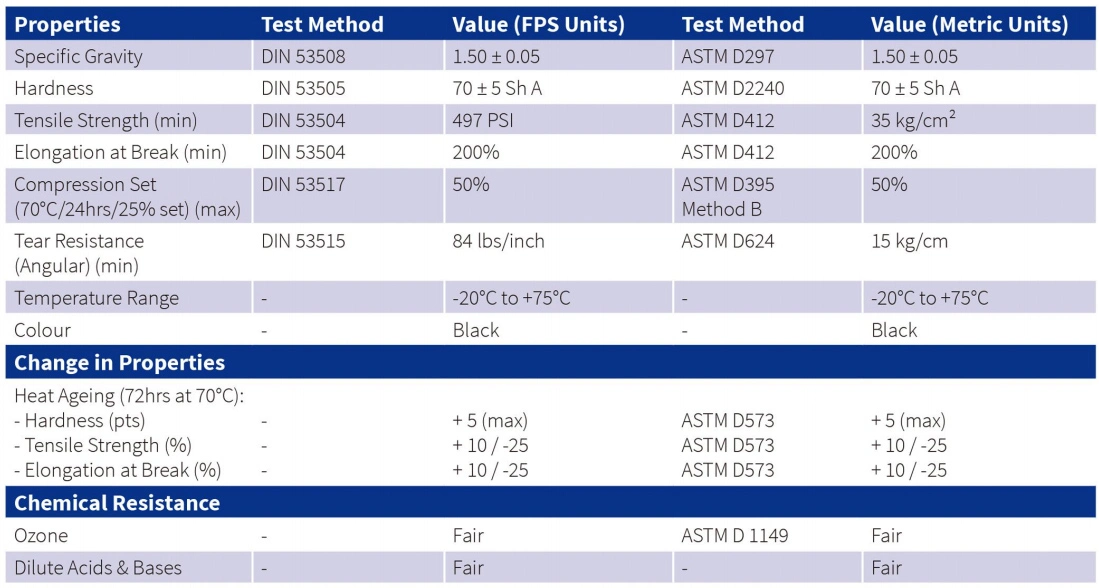

Nitrile rubber sheet (NBR) is a synthetic material that has been used in a wide range of applications for its corrosion resistance to most petroleum-based liquids, oils and greases. Nitrile has moderate mechanical properties and has good resistance to the corrosiveness of aromatic hydrocarbons, but it is not suitable for ketones. If improvement or special material properties are needed, we provide BS 2751, blue food quality, white food quality and blue metal detectable nitrile grades, which meet the requirements of the United Kingdom and the United States.

The nitrile injection molding can be made into gaskets by CNC machinery, cut to suit your requirements, provided by rollers, or made into sleeves. Nitrile rubber is also called nitrile rubber, nitrile rubber and nitrile rubber.

Injection molding nitrile rubber Key Features

Shore Hardness: 70° ± 5°.

Temperature: -20°C up to +75°C.

Good resistance to petroleum, oils and greases.

Commonly used in the automotive sector.

Offers good abrasion resistance and tensile strength.

Injection molding nitrile rubber Product Specification

Place of Origin: China

Brand Name: YOZONE rubber injection molding suppliers

Model Number: tsmcay-37

Pipe Material: 100% Virgin Nitrile (NBR) engineer plastic products

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: Customized.

Length: Customized

Thickness: customized,

Shape: Round

Color: Black, customized

Working Temperature: -55 to +12°C

Tolerance: ±0.05 mm

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Aerospace and electrical

Injection molding nitrile rubber Supply Ability:

100000 Pcs per Month Nitrile butadiene rubber (NBR) Seals and Gasket

Injection molding nitrile rubber Lead Time:

Quantity(Kilograms) 1 - 10 11 - 50 51 - 100 >100 Est. Time(days) 3 5 7 To be negotiated

Injection molding nitrile rubber Packaging & Delivery

Nitrile butadiene rubber (NBR) Seals and Gasket into Carton and Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn