ptfe injection molding process

-

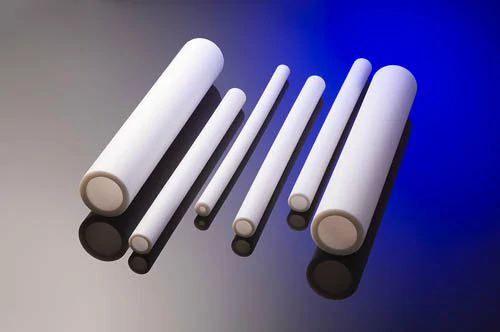

PTFE Molded Tube

PTFE Molded Part Product Specificatin:

Place of Origin: China

Brand Name: YOZONE injection molding supplier

Pipe Material: 100% pure PTFE resin

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: ID 30mm - 600mm, length 10mm - 300mm, customized.

Color: White, transparent black, red, yellow and etc.

Density: 2.16 - 2.3g/cm³

Tolerance: ±0.05 mm

Working Temperature: -180 - 240°C

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

PTFE Molded Part Product Description

As the premier supplier of PTFE molded tubes, our manufacturing process is thoughtfully designed to optimize production costs without compromising on quality. Customers highly appreciate and favor our PTFE tubing for its outstanding performance. Being an ideal raw material among all plastics, it encompasses all the remarkable characteristics of PTFE.

The internally smooth structure of our PTFE tubes contributes to their exceptional strength and flexibility. They possess anti-friction, anti-breakage, and anti-blockage properties, ensuring reliable and smooth operation. Additionally, our PTFE tubes exhibit exceptional resistance to corrosive chemicals, making them suitable for demanding environments. With good dielectric strength and impressive tensile strength, our PTFE tube offer unmatched reliability and durability for a wide range of applications.

Mechanical working allows Yozonetech Molded PTFE Tubes to be shaped into non-standard parts, while also serving as excellent non-sticking materials. Their remarkable temperature tolerance of -180°C to +260°C makes them suitable for various applications. Notably, these tubes boast the lowest frictional factor and the most superior anti-corrosive properties compared to other known plastic materials.

We offer a range of Molded PTFE Tubes with outer diameters (OD) ranging from 30mm to 600mm and lengths varying between 10mm to 300mm per piece. Our selection includes various types of molded PTFE tubes, such as virgin molded PTFE tube, filled molded PTFE tube, fiber glass molded PTFE tube, graphite-filled molded PTFE tube, and bronze-filled molded PTFE tube. Each custom injection mold type serves specific purposes and applications to meet your diverse needs.

PTFE Molded Part Data Sheet

Property Value Unites Method Mechanical Properties Tensile Strength, 23°C 17-23 Mpa - Elongation at break, 23°C 200-500 % - Flexural strength, 23°C No break at flexure D 790 Impact Strength No break - - Yield Strength at 23°C 1450 Psi - Density 2.12-2.17 gm/cu.cm - Thermal Properties Coefficient of Linear Expansion 20-100°C 12 x 10-5 K-1 D 696 Melting Point 327 °C - Thermal Conductivity 0.25 W/m/deg K - Serevice Temperature 260 °C - Processing Temperature 370-395 °C - Electrical Properties Dielectric Strength, short time, 2mm 18 Volts/mum - Surface Arc-Resistance >300 (does not track) sec D 495 Volum Resistivity, dry, @ 50% RH >1018 ohm-cm D 257 Dielectric Constant, 60 to 2 x 109 cps 2.1 ε D 150-81 Other Properties Flame Rating+ VE-0 - UL-94 Resistance to Weathering Excellent - - Specific Gravity 2.12-2.17 - D 792-66 (1979) Coefficient of friction 0.27-0.67 - D 1894

PTFE Molded PartAdvantages

• High strength against pressure

• High temperature resistant

• High dielectric strength

• Non-contaminating

• Smooth inner surface

• Abrasion resistance

• Anti-corrosive

• Anti-friction

• Flexible.

PTFE Molded Part Application:

• Fluid Transfer Devices and Water Processing Systems

• Chemical & Pharmaceutical Manufacturing

• Aerospace &Transportation Technology

• Components & Insulators

• Environmental Science

• Air Sampling

• Electronics

-

PTFE Molded Sheet Plate

PTFE Molded Sheet Product Description

The PTFE sheet is easy to compress and is made of 100% pure PTFE. It is a nationally recognized product that can be used in food processing. Excellent chemical resistance makes it a popular sealing material in the food, beverage and pharmaceutical industries.

This ptfe tube material is usually converted into a washer, which is an easily damaged part because it does not bear the load of the bolt. But it has strong resistance to pressure and can withstand pressures of more than 40,000 psi without losing any sealing ability.

PTFE Molded Sheet Key Features

- Temperature: -240°C to +270 °C (briefly up to +315°C).

- Very soft, extremely compressible and has excellent resistance to many chemicals.

- It is also unaffected by ozone, UV and corona and does not become brittle with age.

PTFE Molded Sheet Product Specification

Place of Origin: China

Brand Name: YOZONE injection molding supplier

Model Number: tsmcay-09

Pipe Material: 100% Virgin PTFE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: customized.

Length: Customized

Shape: Square

Skived Sheet Size: 0.1 - 3 mm

Molded Sheet Size3 - 100 mm

Density: 2.16 - 2.3g/cm³

Tensile strength: 25 MPa

Tolerance: ±0.05 mm

Working Temperature: -60 - 240°C

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Custom injection mold Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

PTFE Molded Sheet Supply Ability

20 Tons per Month Plastic PTFE Extruded Rod

PTFE Molded Sheet Lead Time

Quantity(Kilograms)

1-10: 3 days

11-500: 7 days

501-1000: 15 days

1000+: negotiable

PTFE Molded Sheet Packaging & Delivery

Plastic PTFE Extruded Rod into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

-

PTFE Precise Machined Part Customized OEM Manufacturer

PTFE Injection Molding Product Description

We provide customized machined components, materials including PTFE, PVDF, PCTFE and PEEK. injection molding supplier machined products are very precise in size and have very smooth surfaces. These advantages are of great significance in the pharmaceutical, biotechnology, semiconductor and laboratory equipment markets. The high-quality manufacturing capabilities of these components make high reliability and long-term use possible. At the same time, material selection considerations in the pre-engineering stage are also very important.

PTFE Injection Molding Product Specification

Place of Origin: China

Brand Name: YOZONE ptfe tube

Model Number: tsmcay-04

Pipe Material: 100% Virgin PTFE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: The same to drawing as client supplies

Color: White, transparent black, red, yellow and etc.

Density: 2.16 - 2.3g/cm³

Working Temperature: -180 - 240°C

Custom Injection Mold Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

PTFE Injection Molding Supply Ability

10000 pieces per week Plastic PTFE seals and gasket

PTFE Injection Molding Lead Time

Quantity(Kilograms) 1 - 10 11 - 50 51 - 100 >100 Est. Time(days) 3 5 7 To be negotiated

PTFE Injection Molding Packaging & Delivery

Plastic PTFE extruded Lined Pipe Tube into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

[embed]https://youtu.be/dWMP2I6BEFg[/embed]

[embed]https://youtu.be/wRRsMEd0TJY[/embed]

[embed]https://youtu.be/EO4K4Hk5Qes[/embed]

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn