plastic extrusion tube

-

ETFE Extruded OEM Customized Tubing Manufacturer

ETFE Tubing Product Description:

ETFE tubing is very suitable for high-pressure applications, and its approach is very similar to PEEK tubing.

The high-sensitivity instruments used in the field of life sciences for precise gas and liquid analysis are the application of ETFE tubing which has a wide range of chemical resistance and regulatory characteristics.

Industrial chemical treatment of fluoroplastic tube pipelines enables ETFE (ethylene tetrafluoroethylene) to maintain impressive mechanical properties and corrosion resistance at the highest operating temperature.

Its robust and durable wear resistance is fully utilized.

Key Features of ETFE Tubing:

1. Easily thermoformed

2. Good chemical resistance

3. UL 94 V-O flammability rating

4. Superb stress crack resistance

5. Excellent crush & kink resistance

6. Excellent weathering performance

7. Ideal for high pressure applications

8. FDA conforming & USP Class VI compliant

9. Serviceable from -100°C (-150°F) to 150°C (302°F)

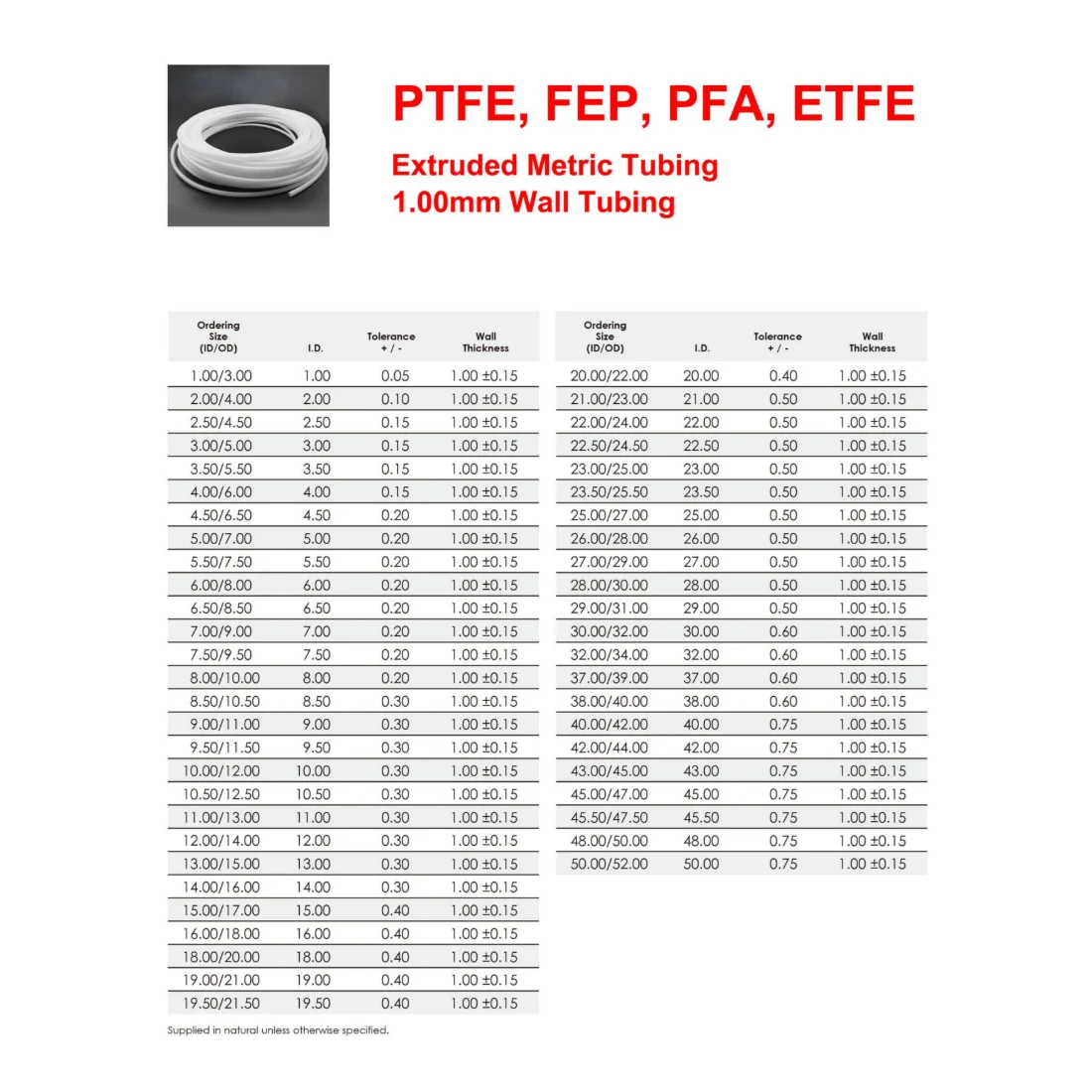

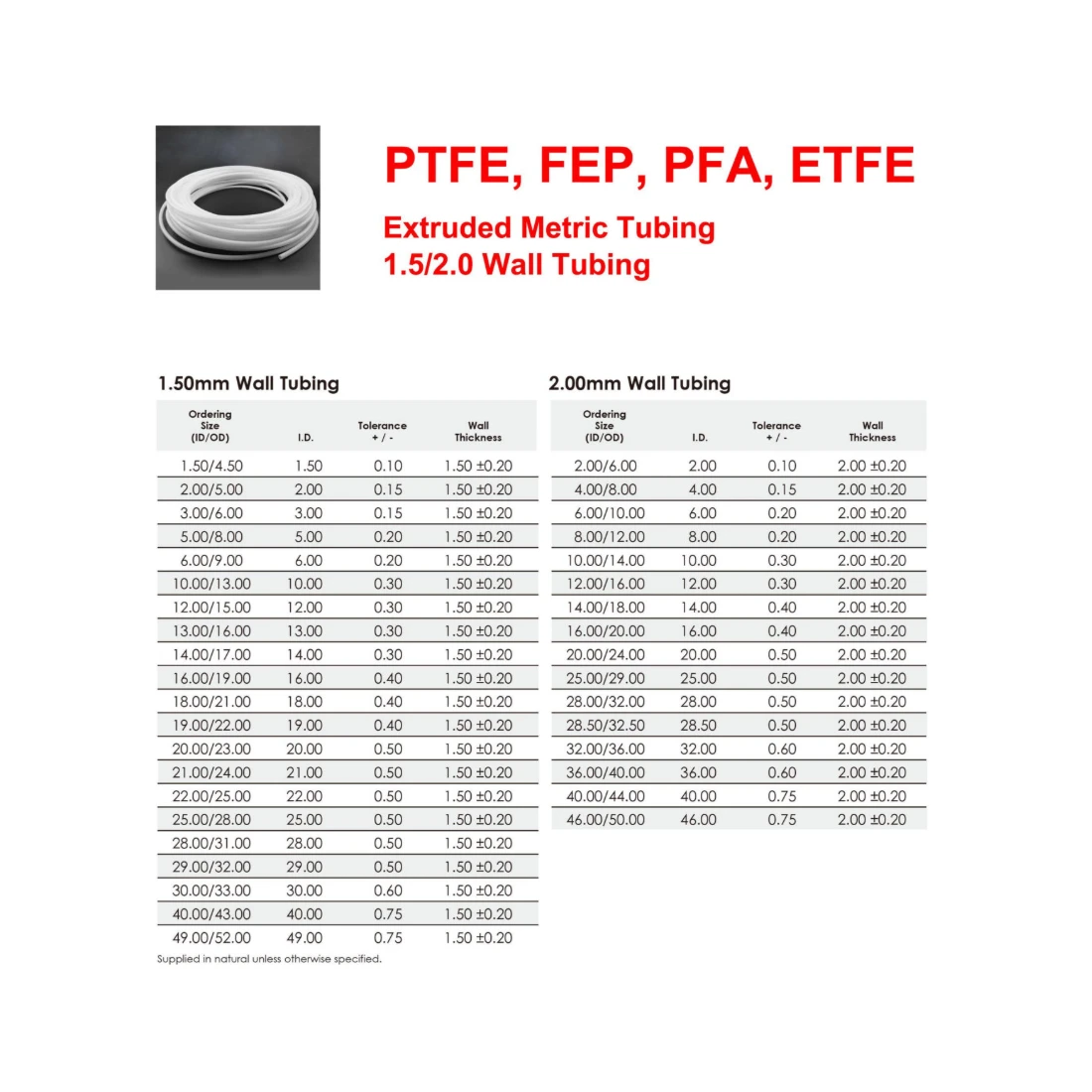

ETFE Tubing Product Specification:

Place of Origin: China

Model Number: tsmcay-20

Pipe Material: 100% Virgin ETFE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: Customized.

Thickness: customized,

Color: White, customized.

Working temperature: -200°C - +150°C

Tolerance: ±0.05 mm

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Test: SGS passed

Sample: Free

Payment: T/T

Extruded tube Service Life: Depends on environment, please kindly consult our engineers.

Extruded Plastic Tube Application: Petroleum transportation, food procession, electrical and etc.

ETFE Tubing Supply Ability:

100000 Meter/Meters per Month ETFE Tube

ETFE Tubing Lead Time:

Quantity(Kilograms) 1 - 10 11 - 50 51 - 100 >100 Est. Time(days) 3 5 7 To be negotiated

ETFE Tubing Packaging & Delivery

ETFE Tube into Carton and Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

-

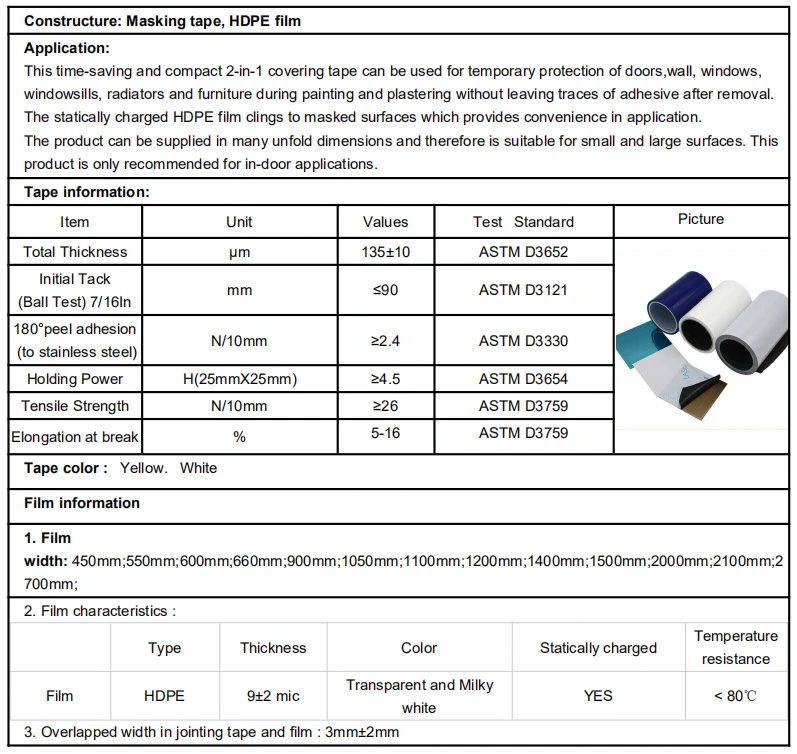

PE 100% Virgin Customized Extruded OEM Tubing Manufacturer

Extruded PE Tube Product Description

Our transparent unreinforced PVC pipe is made of a flexible PVC compound. The compound contains additives that have been approved for food. As there is no reinforcement, it is not recommended to use fluoroplastic tube for pressure treatment. Used with low pressure solids, liquids and gases. Can also be used in food contact applications.

Extruded PE Tube Key Features

- Temperature: -15°C up to +60°C.

- Good flexibility.

- FDA approved for food contact applications.

- Suitable for low pressure solids, liquids and gases.

Availability

Also available: Clear unreinforced PVC tubing is also available in red, orange, yellow, green, blue and black (subject to minimum quantities). 6701S - Soft Grade PVC Tubing is also available.

Extruded PE Tube Product Specification

Place of Origin: China

Brand Name: YOZONE

Model Number: tsmcay-28

Pipe Material: 100% Virgin PE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: Customized.

Length: Customized

Thickness: customized,

Shape: Round

Color: Customized.

Working temperature: -60 to +60°C

Tolerance: ±0.05 mm

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Extruded tube Service Life: Depends on environment, please kindly consult our engineers.

Extruded Plastic Tube Application: Petroleum transportation, food procession, electrical and etc.

Extruded PE Tube Supply Ability:

100000 Meter/Meters per Month PE Film

Extruded PE Tube Lead Time:

Quantity(Kilograms) 1 - 10 11 - 50 51 - 100 >100 Est. Time(days) 3 5 7 To be negotiated

Extruded PE Tube Packaging & Delivery:

PE Film into Carton and Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

-

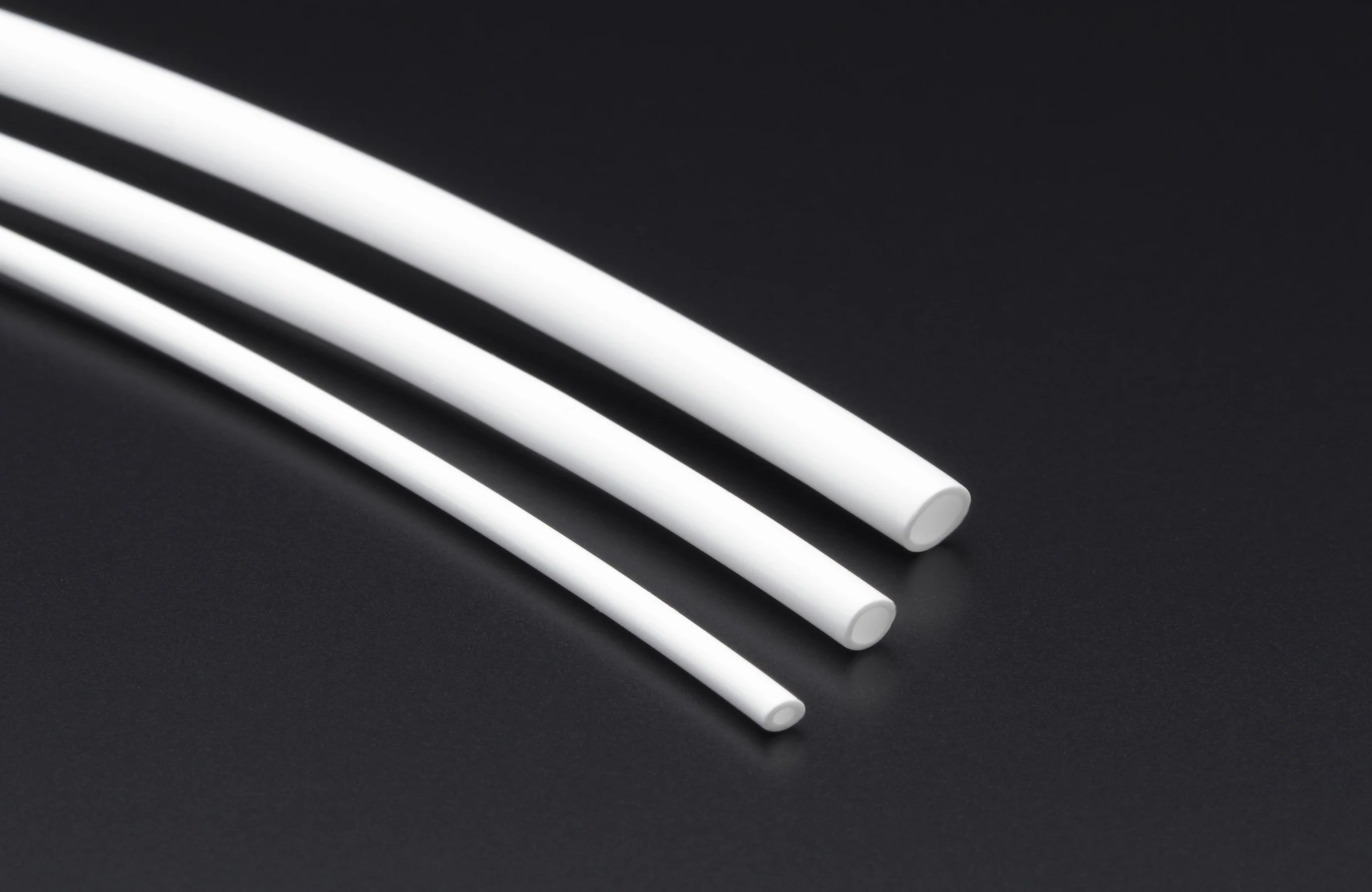

ePTFE 100% Virgin Customized Tubing OEM Manufacturer

ePTFE 100% Virgin Customized Tubing Product Description:

Extruded PTFE (ePTFE) tubes are manufactured through a complex process that involves blending PTFE fine powder resin with an extrusion aid, followed by extrusion through a die to define its profile. The extruded material is then stretched under heat to achieve a soft, marshmallow-like texture. The stretching parameters play a crucial role in determining the final characteristics of the ePTFE, including texture and porosity.

Applications of plastic extruded tubing are diverse due to their unique properties. The texture is favored for gasket materials, while porosity is utilized in membranes and filter applications. The porosity allows gases and vapors to pass through while blocking liquids, making ePTFE ideal for venting and high-end filtration applications. It ensures leak-proof systems while allowing excess gases to escape and prevents water from entering electronic enclosures while evacuating accidental moisture buildup.

Advantages of fluoroplastic tube include the combination of texture and porosity, making them highly flexible and resistant to kinking, unlike regular PTFE tubes. They are suitable for systems requiring liquid passage and vapor expulsion. extruded plastic tube find applications in chemical and medical fields, including surgical grafts and stents, in addition to automotive uses.

Despite the challenges in manufacturing Extruded tubes, overcoming these difficulties results in a versatile and highly effective product with a wide range of applications.

Product Specification

Place of Origin: China

Standard: Medical and industry

Application: Chemical water and gas filtration, automobile oxygen sensor for sealing, other application need pore duffusion of gas.

Tensile Strength: excellent

Color: black, white, red, yellow, blue, green, transparent; other colors available for customization.

Certification: ROHS

Feature: Excellent Electrical Insulation

Size: Customized Size

Spec: From OD1.5mm to OD13mm, one piece continuous length can be made to several meters without knots, special specifications can be customized according to requirements.

Sample: Free Sample Avaliable

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn