injection plastic molding

-

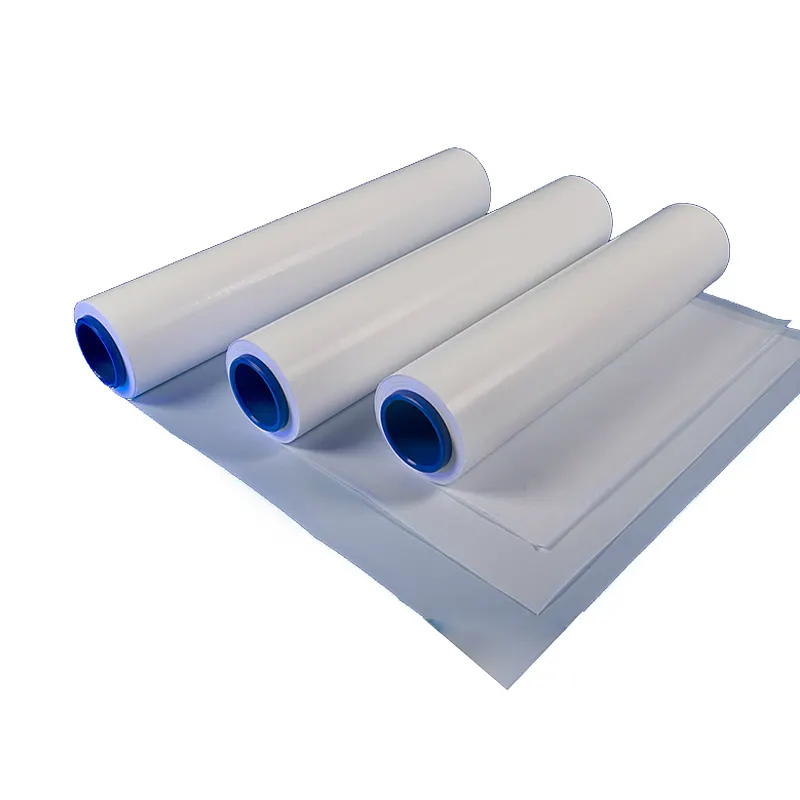

PTFE Film Customized OEM Manufacturer

PTFE Film Product Description

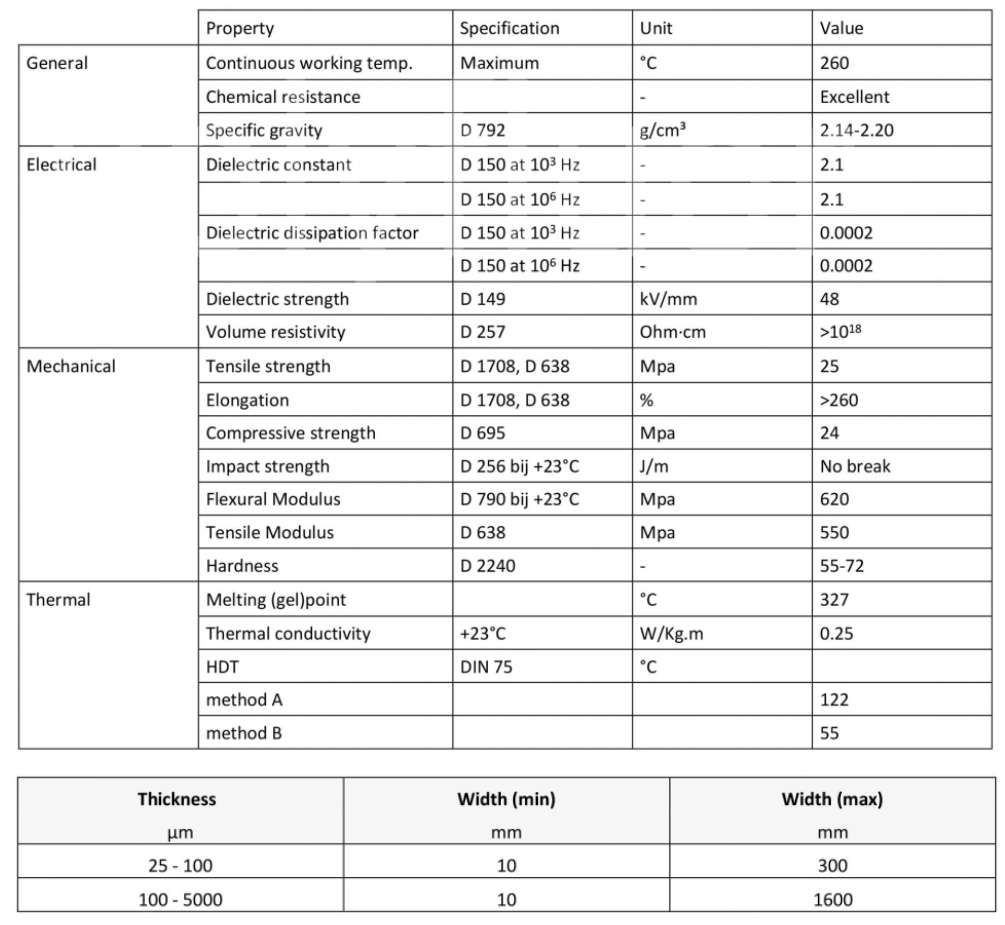

PTFE film is a single-layer and multi-layer film produced by the casting method. Due to this unique process, PTFE film (polytetrafluoroethylene) has many high-performance characteristics superior to leaky tape or extruded film. PTFE tube material structure is uniform, has excellent chemical, physical and electrical properties, and its thickness is strictly controlled (+/-10%). Oxygen sensors and similar devices in biomedicine and other instruments use the ability of their semi-permeable membranes. PTFE provides semi-finished cast PTFE films on standard rolls, or converted into custom injection mold shaped finished stamping components, ready to be assembled on your equipment at any time. .

PTFE Film Product Specification

Place of Origin: China

Brand Name: YOZONE injection molding supplier

Model Number: tsmcay-11

Pipe Material: 100% Virgin PTFE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: customized.

Length: Customized

Thickness: Min. 0.03 mm, customized.

Shape: Round

Weight: Very heavy

Density: 2.16 - 2.3g/cm³

Color: White (customized)

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: parts in steam environments.

PTFE Film Supply Ability

Lead Time

Quantity(Kilograms) 1 - 10 11 - 100 >100 Est. Time(days) 5 8 To be negotiated

PTFE Film Packaging & Delivery

Plastic PTFE Film into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

We are one of the professional manufacturers and suppliers of ptfe convoluted tubing in China, if you are interested in our ptfe tubing,custom ptfe convoluted tubing,high purity ptfe convoluted tubing made in China, please contact us immediately!

[embed]https://youtu.be/4UbfEJhhOVM[/embed]

-

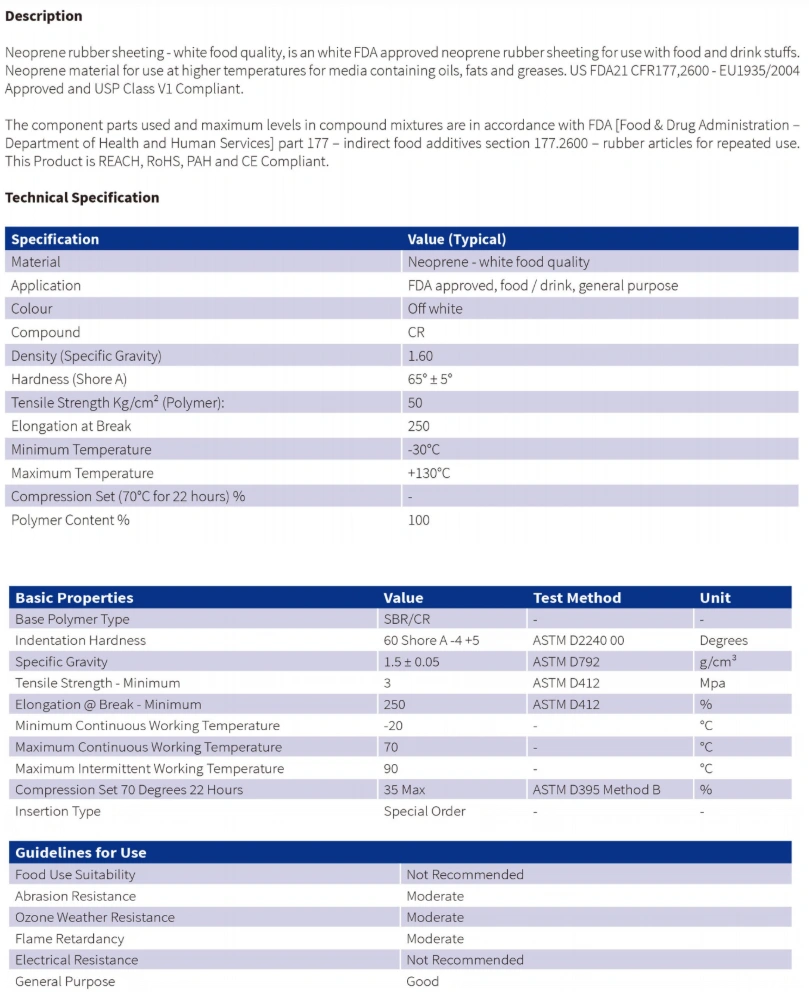

Neoprene Injection Molding Part

Neoprene Injection Molding Product Description

1. Chloroprene rubber film (CR) is a synthetic material, and its excellent properties of aging resistance, ozone resistance and weathering resistance are its excellent properties, so it will usually be used for exterior applications of gaskets, linings, weather strips and casings . It has moderate corrosion resistance to animal and vegetable oils and inorganic salts, but is not suitable for use with aromatic hydrocarbons and ketone compounds. If special characteristics and standards are needed, other grades such as flame retardant and bs2752 can also be provided. For food and pharmaceutical applications, rubber injection molding manufacturer provide white food neoprene in compliance with European Community and FDA regulations.

2. The neoprene sheet injection molding can be provided in full rolls, or cut into customized lengths or customized shapes using internal CNC machinery.

3. Neoprene is also called neoprene, neoprene or pc rubber.

Neoprene Injection Molding Key Features

1 Shore Hardness: 60° ± 5°.

2 Temperature: -30°C up to +70°C.

3 Excellent resistance to weathering.

4 Good resistance to ageing and ozone.

5 Popular material option for external applications.

Neoprene Injection Molding Product Specification

Pipe Material: 100% Virgin Neoprene

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: engineer plastic products Customized.

Length: Customized

Thickness: customized,

Shape: Round

Color: Black, customized

Working Temperature: -40 to +150°C

Tolerance: ±0.05 mm

Electrical Property: Insulation Resistant

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Aerospace and electrical

Neoprene Injection Molding Supply Ability

100000 Pcs per Month Neoprene Seals and Gaskets

-

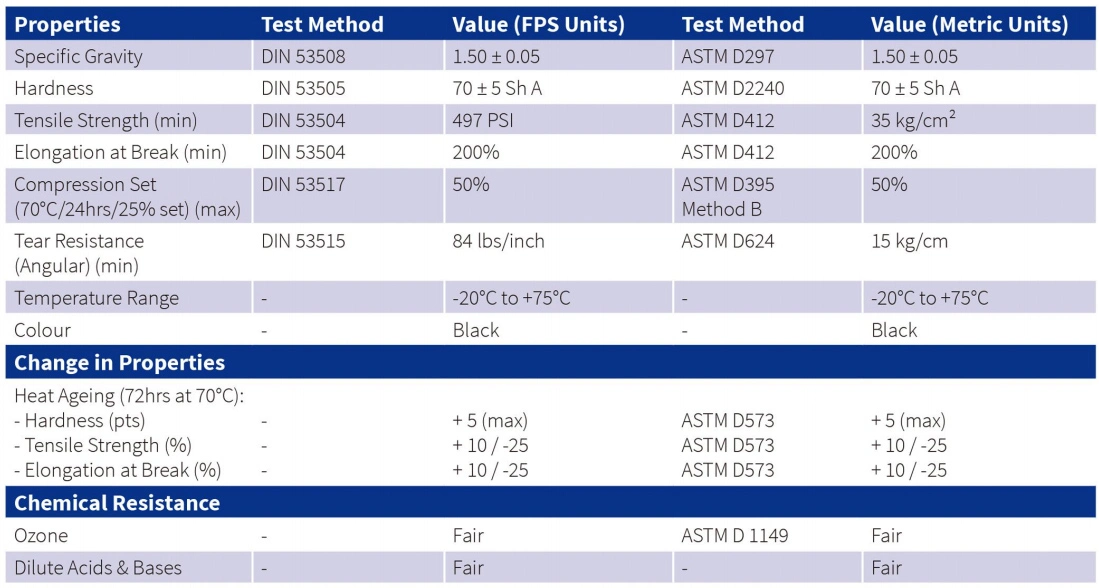

Nitrile (NBR) Injection Molding Part

Injection molding nitrile rubber Product Description

Nitrile rubber sheet (NBR) is a synthetic material that has been used in a wide range of applications for its corrosion resistance to most petroleum-based liquids, oils and greases. Nitrile has moderate mechanical properties and has good resistance to the corrosiveness of aromatic hydrocarbons, but it is not suitable for ketones. If improvement or special material properties are needed, we provide BS 2751, blue food quality, white food quality and blue metal detectable nitrile grades, which meet the requirements of the United Kingdom and the United States.

The nitrile injection molding can be made into gaskets by CNC machinery, cut to suit your requirements, provided by rollers, or made into sleeves. Nitrile rubber is also called nitrile rubber, nitrile rubber and nitrile rubber.

Injection molding nitrile rubber Key Features

Shore Hardness: 70° ± 5°.

Temperature: -20°C up to +75°C.

Good resistance to petroleum, oils and greases.

Commonly used in the automotive sector.

Offers good abrasion resistance and tensile strength.

Injection molding nitrile rubber Product Specification

Place of Origin: China

Brand Name: YOZONE rubber injection molding suppliers

Model Number: tsmcay-37

Pipe Material: 100% Virgin Nitrile (NBR) engineer plastic products

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: Customized.

Length: Customized

Thickness: customized,

Shape: Round

Color: Black, customized

Working Temperature: -55 to +12°C

Tolerance: ±0.05 mm

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Aerospace and electrical

Injection molding nitrile rubber Supply Ability:

100000 Pcs per Month Nitrile butadiene rubber (NBR) Seals and Gasket

Injection molding nitrile rubber Lead Time:

Quantity(Kilograms) 1 - 10 11 - 50 51 - 100 >100 Est. Time(days) 3 5 7 To be negotiated

Injection molding nitrile rubber Packaging & Delivery

Nitrile butadiene rubber (NBR) Seals and Gasket into Carton and Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

-

UHMWPE Sheet Customized OEM Manufacturer

UHMWPE (Ultra High Molecular Weight Polyethylene) is a renowned machinable plastic that boasts exceptional durability, versatility, and cost-effectiveness. It is highly sought after for its impressive resistance to abrasion, impact, and chemicals. The molecular weight of UHMWPE typically ranges from 3.1 million to 100 million grams per mole, with higher molecular weights correlating to improved abrasion resistance.

The Anti-static UHMWPE sheet injection molding is specifically designed for applications where static electricity can cause issues in manufacturing environments. With a surface resistance ranging from 105 to 109 (ohms/cm2), this type of UHMWPE is well-suited to handle challenging conditions, such as those found in grain elevators and munition plants, effectively protecting materials from static discharges. Engineer plastic products high heat and corrosion resistance make it ideal for safeguarding robotics and other sensitive products from dust accumulation and electrical charge buildup.

UHMWPE Sheet Key Features of Anti-static UHMWPE:

- Prevents static electricity buildup, making it suitable for volatile environments like munitions plants and grain handling facilities.

- Surface resistance ranges from 105 to 109 (ohms/cm2) for effective anti-static properties.

- Available in sheet, rod, board, and profiles, tailored for situations where dust and static electricity pose significant challenges.

- Possesses a low coefficient of friction, making it ideal for applications like conveyor guard rails, augers, belt scrapers, and idler rollers.

- Self-lubricating formula with no moisture absorption, contributing to its high durability, low friction, and wear resistance.

- Easily machined with common woodworking tools, adding to its versatility.

- Demonstrates excellent chemical resistance, ensuring longevity in various environments.

In summary, Anti-static UHMWPE serves as an exceptional material for applications where static electricity and dust accumulation are major concerns. Its anti-static properties, low coefficient of friction, and self-lubricating nature make it a preferred choice for numerous industrial applications, rubber injection molding suppliers providing outstanding abrasion resistance and impact strength, even at low temperatures. Moreover, its resistance to chemical corrosion further enhances its reliability and durability in various settings.

-

HDPE Rod Customized OEM Manufacturer

HDPE Rod Product Specification

Place of Origin: China

Brand Name: YOZONE rubber injection molding suppliers

Model Number: tsmcay-06

Pipe Material: 100% pure PTFE

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: DN6 - DN 150, customized.

Length: Customized

Shape: Round

Color: White, transparent black, red, yellow and etc.

Density: 2.16 - 2.3g/cm³

Tolerance: ±0.05 mm

Tensile strength: 20Mpa (different specification are different)

Working Temperature: -60 - 240°C

Chemical Resistance: stable in most medium.

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Petroleum transportation, food procession, electrical and etc.

HDPE Rod Supply Ability

Supply Ability:

2000 Meters per Month Plastic PTFE Convoluted Tube

HDPE Rod Packaging & Delivery

Packaging Details

Plastic PTFE extruded Lined Pipe Tube into Spool in Carton or Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

HDPE (High-density polyethylene) injection molding is a versatile thermoplastic derived from petroleum, known for its exceptional strength, impact resistance, and low coefficient of friction. Its numerous benefits, including affordability and eco-friendliness, have made it the preferred plastic material for various manufacturers.

Key Features and Benefits of HDPE:

- Long-lasting, low maintenance, and safe, with FDA approval for use in the food processing industry.

- Moisture, stain, and odor resistant, providing excellent hygiene and cleanliness.

- Corrosion resistant, splinter-free, and rot-resistant, ensuring durability in water, chemical, and solvent-exposed areas.

- High strength-to-density ratio, combined with easy meltable and moldable properties.

- Easy to cut, machine, fabricate, weld, or mechanically fasten to meet specific application requirements.

- Environmentally friendly, as it is easily recyclable, reducing plastic waste and promoting sustainable production.

Common Applications of HDPE:

- Bottling lines and conveyor systems

- Cutting boards

- Outdoor furniture

- Material handling strips and components

- Signage, fixtures, and displays

Moreover, HDPE engineer plastic products is widely used in bottles, kick plates, fuel tanks, lockers, playground equipment, packaging, water tanks, food processing equipment, chute linings, and boat, RV, and emergency vehicle interiors.

HDPE Standard Sizes, Thicknesses, and Colors:

Yozonetech offers a wide range of HDPE options, including various sizes, shapes, thicknesses, and colors. Additionally, they provide CNC cutting services to optimize yield and reduce overall costs. Customers can inquire about cut-to-size services when contacting the company.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn