How to Use Heat Shrink Tubing

July 4, 2025

During your work on electrical projects or when you need cable and wire protection, you did not know how to use heat shrink tubing. It is a completely adaptable tool that can become a powerful ally in the insulation and protection of your wires and cables, and that is the reason why we are excited to present to you an easily understandable guide that will help you to master how to employ heat shrink and also gain some clarity about YOZONE’s high-quality products.

Step-by-Step Guide to Using Heat Shrink Tubing

Using heat shrink tubing is a foolproof method that can seriously boost the service life and safety of your electrical connections. Here is the proper way to carry it out:

1. Choose the Right Tubing

First of all, you need to choose the right size of tubing that fits the purpose of your project. Give a thought to the wire diameter, the thermal capacity required, the temperature that will be borne by your heat shrink in the working environment, and also the additional protective factors like abrasion, UV light, and chemical resistance. The YOZONE range comprises several types of heat shrink tubing to satisfy every different requirement. An example from the wide range is the usage of YOZONE’s Polyolefin Fire Retardant Insulation Heat Shrinking Tubing, which is suitable for applications where heat resistance is crucial.

2. Measure and Cut

Then start by getting the precise length of the tubing you need. To be on the safe side, it is always better to choose a little more than you need. As soon as you are clear about the length, use a knife or scissors to accomplish the task.

3. Slide the Tubing into Place

Then you need to transfer the heat shrink tubing from its original place and onto the cable or wire joint. Be sure that the temperature is appropriate before heating it. Remember! The tubing should be exactly in the center where you want to insulate or protect the area.

4. Heat the Tubing

Now, the most critical part is to heat the tubing. Have with you a heat gun or a hairdryer set to high. Stand 10-15 cm away from the source of heat and slowly move it up and down, ensuring the heat is evenly distributed. You will notice the tubing shrink, leaving no room between it and the wire, giving you a secure seal.

5. Check the Result

As soon as the tubing is cold, carefully examine it to see if it has completely shrunk and is sealed. There should be no wrinkles or gaps. What you should see is a clean and professional-looking result that guarantees good insulation and protection.

Why Choose YOZONE’s Heat Shrink Tubing?

When using heat shrink tubing, the quality of the product matters. Here’s why YOZONE stands out:

High-Quality Materials

YOZONE uses the best materials such as polyolefin, PTFE, FEP, etc. For example, their PTFE Dual Wall Heat Shrink Tubing not only provides excellent electrical insulation but also has great chemical resistance even at the most demanding conditions.

Wide Range of Options

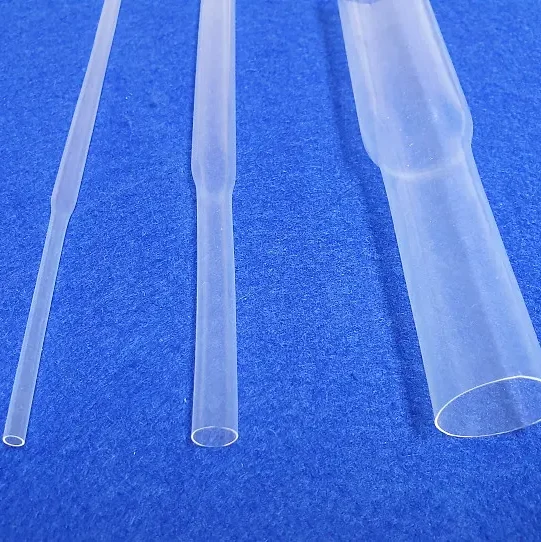

The company provides different choices and models of both single-wall and double-wall heat shrink tubing. The two-layer construction with the double wall tubing delivers supreme insulation and reflects the fact that it is sturdy enough for extreme surroundings.

Easy to Use

YOZONE-based products are carefully designed to avoid the complexity inherent in installation processes. They do shrink in a uniform manner and are capable of conforming themselves to all types of irregular shapes, as well as consist of all user-friendly features to ensure the peaceful and uninterrupted development of your tasks.

Reliable Performance

The certificates YOZONE possesses — like ISO 9001, FDA, ROHS, and CE — are a guarantee of the safety and quality the shrink tubing holds, and you are safe to trust it. Even in harsh conditions, they are the kind of products that will serve for a long period.

Common Applications of Heat Shrink Tubing

Common Applications of Heat Shrink Tubing

The heat-shrink tubing has various useful applications:

1. Electrical Insulation: It’s perfect for isolating the wire connections and thus preventing shorts.

2. Environmental Protection: This way, cables and wires are protected from damp, dirt, and chemical substances.

3. Strain Relief: Here, the tubing is used to hold the electrical connectors and not to damage them by bending or screwing up their position in any way.

4. Identification: The idea of using different colors to differentiate the wires is the easiest way to go. So, then it can also be that you are using the printed types to label and sort the wires effectively.

Conclusion

Using heat shrink tubing is a simple but very practical method of making your electrical work safe and durable. It is an added advantage that by including their single wall heat shrink tube and dual wall heat shrink tube options, YOZONE assures you of high-quality heat shrink tubing set for all applications, big or small. So, the reminder in the next project is to follow these guidelines when insulating or protecting wires and to connect us for good performance.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn