How to purchase and import PFA tubes from China?

August 7, 2023

What is PFA?

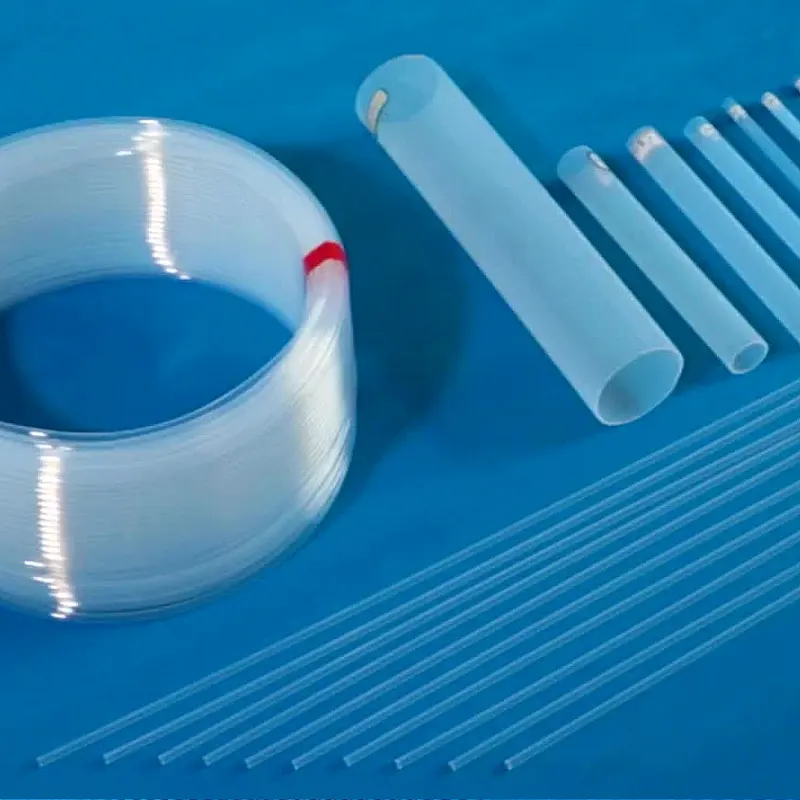

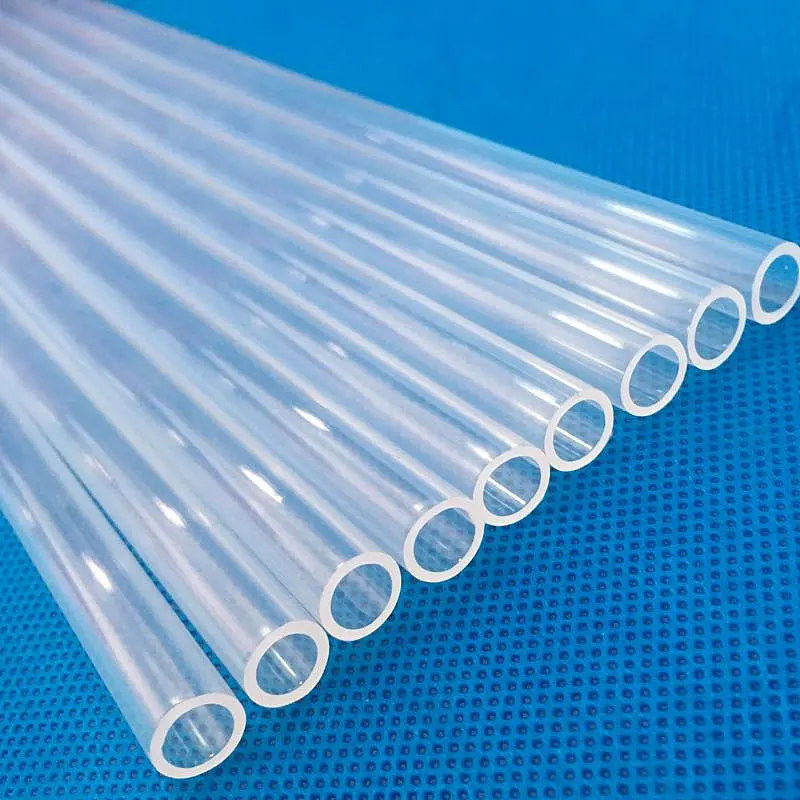

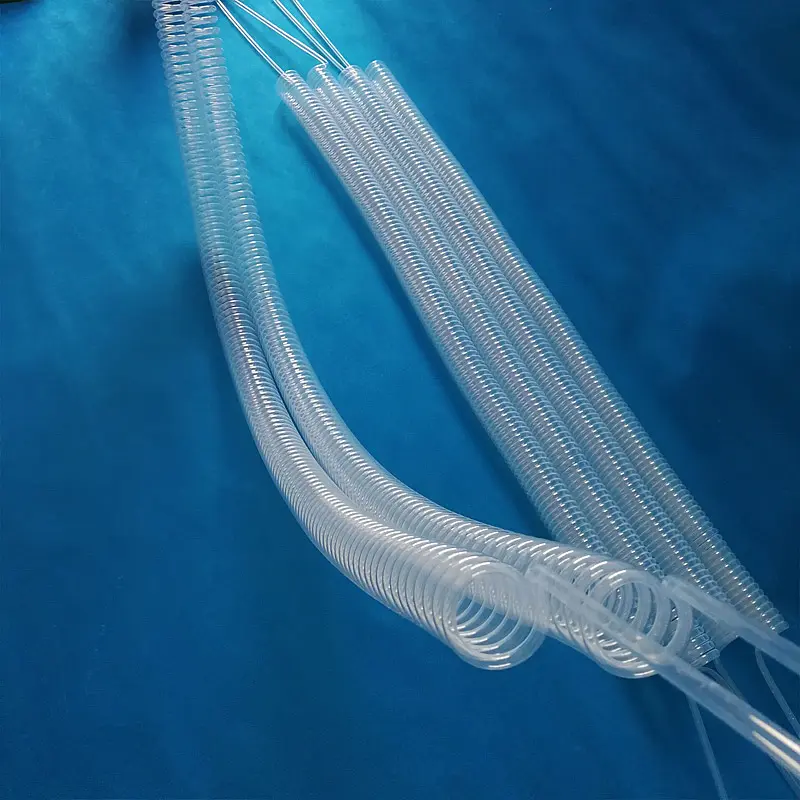

PFA tube is a special type of plastic conduit made from Perfluoroalkoxy (PFA) material. PFA is a polymer with excellent chemical resistance and high-temperature tolerance, commonly used for fluid transfer in industries such as chemical manufacturing, semiconductor fabrication, and pharmaceutical production.

| Characteristics | Description |

| Corrosion Resistance | Excellent chemical resistance, suitable for various corrosive media. |

| High-Temperature Tolerance | Can be used stably at temperatures up to 260 degrees Celsius (500 degrees Fahrenheit). |

| Inert Surface | Inert surface that minimizes substance adhesion, reducing fluid resistance. |

| Electrical Insulation | Good electrical insulation properties, suitable for electrical environments. |

| Processability | Easy to process, can be manufactured into various sizes and shapes of tubes. |

| Wide Application Range | Widely used in industries such as chemical manufacturing, semiconductor fabrication, pharmaceutical production, etc. |

| Long-Term Stability | Maintains stability over extended periods in harsh environments, prolonging lifespan. |

| Transparency | High transparency allows for observation of fluid transfer processes. |

| Lightweight and Durable | Lightweight material with good strength and toughness. |

| Anti-Adhesive | Discourages substance adhesion, reducing the formation of internal deposits. |

| Environmentally Friendly | Does not release harmful substances, in line with environmental standards. |

Applications of PFA Tubes:

1. Chemical Industry:

PFA tubes are frequently used for transporting corrosive chemicals, acids, alkalis, solvents, etc., as their excellent corrosion resistance ensures safe and stable fluid transfer in chemical production processes.

2. Semiconductor Manufacturing:

In semiconductor fabrication processes, handling high-purity chemicals and corrosive media is necessary. PFA tubes are employed for conveying these liquids to maintain process reliability and purity.

3. Pharmaceutical Production:

PFA tubes are used for conveying pharmaceutical raw materials, reagents, solvents, etc., during pharmaceutical manufacturing. Their inert surface ensures no impact on drug purity and quality.

4. Laboratory Applications:

PFA tubes can be utilized for chemical reagent transfer in laboratories, especially when reagents react with common materials or require high-temperature conditions.

5. Food and Beverage Industry:

PFA tubes can serve as conduits in food and beverage production processes that involve high temperatures, acidic or alkaline conditions, or specific chemicals.

6. Coating and Spraying:

The anti-adhesive properties of PFA material make it suitable for coating and spraying industries, used for chemically resistant surface coating.

7. Environmental Applications:

PFA material’s environmental friendliness and lack of harmful substance release make it useful for handling or transporting liquids related to environmental protection.

8. Medical Devices:

In certain medical devices, PFA tubes are employed for delivering medications, liquids, or biological samples.

Key Points for Purchasing PTFE Tubes from China:

1. Supplier Selection:

Look for reputable suppliers or manufacturers. You can search for potential suppliers through the internet, industry exhibitions, trade platforms, etc., and review their customer feedback and certifications.

2. Product Quality Certification:

Ensure that the supplier’s products meet quality standards, such as ISO certification or other industry standards. This helps guarantee the reliability and quality of the products.

3. Specifications and Sizes:

Clearly define the specifications, sizes, and technical requirements of the PFA tubes you need. Communicate with the supplier to ensure they can provide products that meet your requirements.

4. Price Comparison:

Communicate with multiple suppliers to get different quotations. Note that price is not the sole consideration; quality and service should also factor into your decision.

5. Sample Testing:

If possible, request samples from the supplier for testing and evaluation. This can help you verify the quality and suitability of the products.

6. Delivery Time:

Understand the supplier’s delivery time to ensure they can provide the products you need on time.

7. After-Sales Service:

Inquire about the supplier’s after-sales service policies, including quality assurance, return and exchange policies, etc. Good after-sales service ensures that any issues during usage are promptly addressed.

8. Contracts and Payment Terms:

Ensure that you sign a contract with the supplier, clearly stating product specifications, delivery dates, prices, and payment terms.

9. Logistics and Shipping:

Understand the supplier’s logistics and shipping methods to ensure that products are delivered on time and in good condition.

10. Regulations and Legal Requirements:

Ensure that your purchasing process complies with local and national regulations and legal requirements, including quality standards and import requirements.

How to ensure quality in advance?

YOZONETECH will provide accurate sizes and sufficient quantities of free samples according to customer requirements to ensure the reliability of test results. We have a large inventory to ensure the delivery of samples or finished products.

Types and Related Applications of PFA Tubes

| Size | Inner Diameter Range | Thickness | Application Areas |

| Small | 1/8″ – 1/2″ | Thin | High-temperature tolerance, suitable for laboratory and small-scale chemical reactions |

| Medium | 3/4″ – 2″ | Medium | Widely used in industrial fluid transfer, food and beverage production, semiconductor manufacturing |

| Large | 2.5″ and above | Thick | Beneficial in chemical engineering, large-scale fluid conveying, semiconductor production equipment |

PFA Tube – Processing Techniques

The processing of PFA tubes typically involves techniques used for thermoplastic plastics to shape them into desired dimensions and forms.It’s important to note that PFA is a specialized high-performance material, and the processing must be carried out under suitable temperature and pressure conditions to ensure the resulting tubes possess the required performance and quality. The processing steps might vary depending on different manufacturers and equipment.Here are the general processing steps for PFA tubes:

1. Preparation:

PFA material usually requires pre-processing to remove surface impurities and contaminants before processing. This can involve cleaning and drying.

2. Cutting:

PFA tubing is cut to the desired length using cutting tools, saws, or other suitable equipment.

3. Heating Softening:

PFA, being a thermoplastic material, needs to be softened through heating for further processing. Heating can be done using hot air guns, ovens, or heated plates.

4. Extrusion Molding:

The softened PFA material can be extruded into shape using an extrusion machine, forming the outer shape of the tube. The extrusion machine heats and extrudes the material, which is then formed to the desired shape through molds.

5. Cooling and Solidification:

The extruded tubing needs to be cooled and solidified to maintain the desired shape and dimensions. This can be achieved using cooling water or other cooling equipment.

6. Post-Processing:

The processed tubing might require trimming, polishing, or other post-processing steps to ensure smooth surfaces and accurate dimensions.

7. Quality Inspection:

Quality checks are performed to ensure that the processed PFA tubes meet specifications and quality requirements. Inspection includes aspects like appearance, dimensions, and bending.

8. Packaging and Delivery:

Processed PFA tubes need proper packaging to prevent damage during transportation. They can then be delivered to customers or distributors.

☛ Learn More

Yozonetech FEP, PFA, and PTFE tube Website ➤ https://www.chinaptfetube.com/

Facebook ➤ https://www.facebook.com/ChinaFEPtube

LinkedIn ➤ https://www.linkedin.com/company/chinaptfetube/

YouTube ➤ https://www.youtube.com/channel/UCWzNjAgghr0B7tXDrP_jwfA

————————————————————————–

☛ Enquiry Service:

Email: ptfetube@yozonetech.cn

WhatsApp: wa.me/008613752771911

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn