fep shrink tubing

-

FEP Insulation Anti-Uv 1.6:1 1.3:1 Heat Shrink Diameter 1-150mm Tubing Sleeves

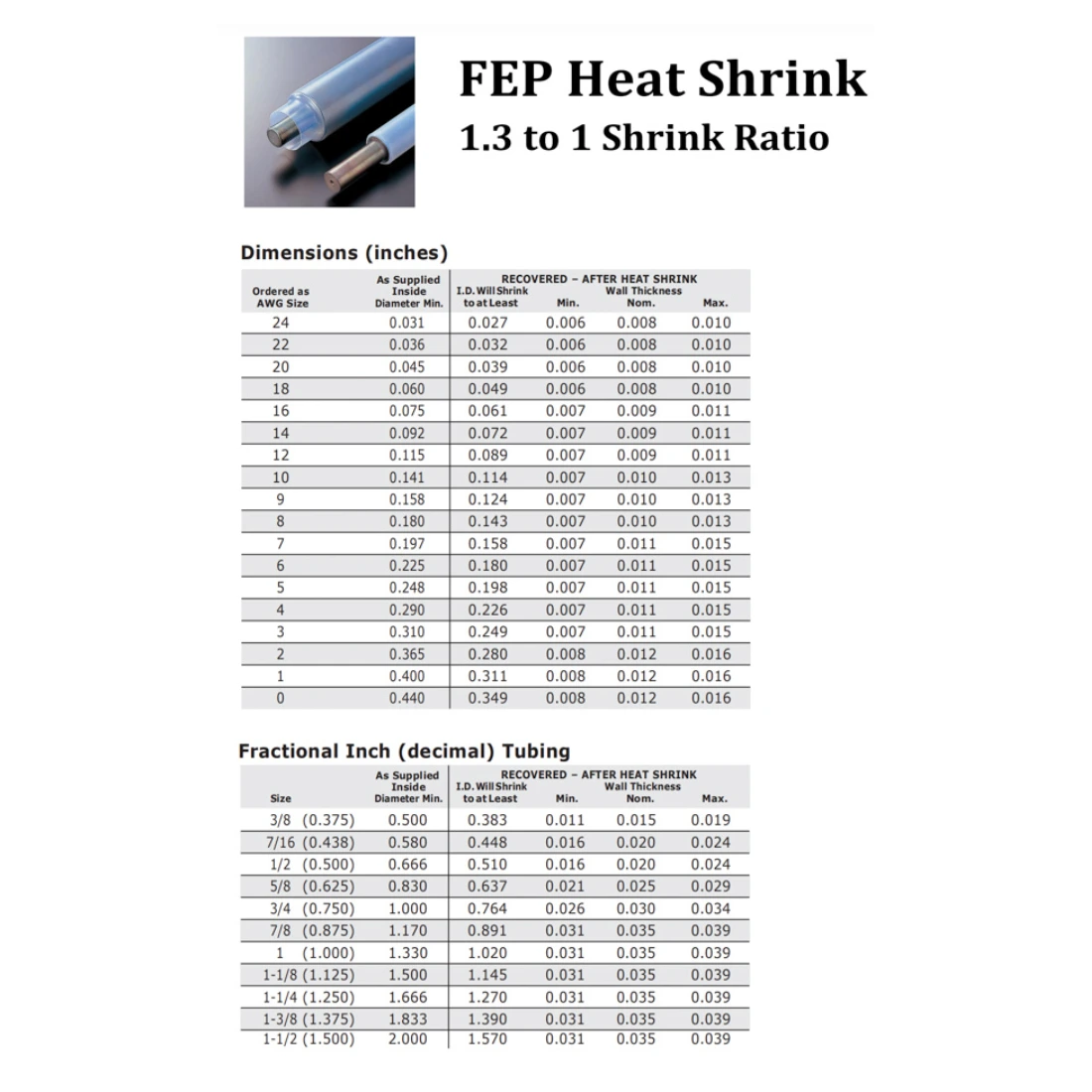

Heat shrink tubing Product Description

The properties of FEP copolymer are similar to those of PTEE, but its heat resistance is slightly lower, and it can work at- 85℃ + 205℃ for a long time, and at - 200℃ +300℃ for a short time ; it has high impact strength, creep resistance, and low temperature flexibility, which is better than PTEE ; its crystallinity is different with the heat treatment temperature, and its molding process ability is good ; it is non-toxic, non sticky, electrical insulation, wear resistance and chemical stability are better than PTEE It has excellent high and low temperature resistance, oil resistance and chemical reagent resistance. It is mainly used for insulation sheath of mechanical equipment, medical equipment, communication equipment, chemical industry, automobile industry, main insulation of motor rotor, water treatment, coating of roller barrel in oil field.

[embed]https://youtu.be/-hgILz2qbT4[/embed]

[embed]https://youtu.be/Z_qx0oQW3R8[/embed]

FEP heat shrink tubing medical Product features

Corrosion resistance : only fluorine and alkali metals play a role in it at high temperature, and have no effect on all other inorganic organic acids, bases and esters.

High and low temperature resistance :- 85℃to 200 ℃ high temperature

Low water absorption : low water absorption < 0.01%

Incombustibility : no combustion in the air (oxygen index> 95 vo.%)

Non toxic: physiological inertia

High transparency: low refractive index in the plastic

Non stick: hydrophobic, oil repellent

Electrical property : high insulation : the dielectric constant viscosity of 60hz- 60mhz at high and low temperature is 2.1.Even if the surface is damaged by diving, there will be no conductive track.Volume resistance > 1018 Q m, surface resistance > 1013 Q, arc resistance 》165S No leakage of electricity

Low friction: dynamic friction coefficient 0.2-0.3

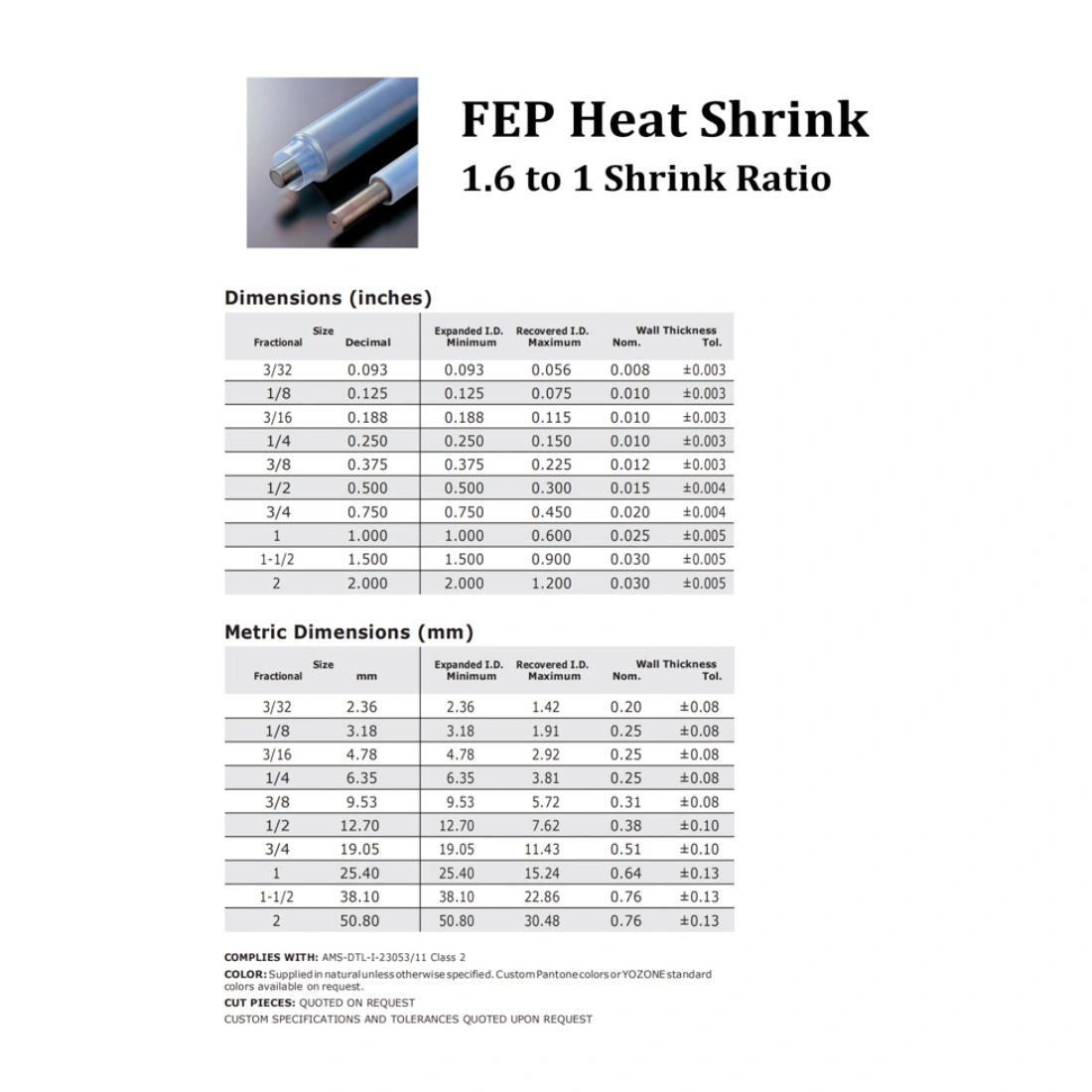

Machinability : easy for secondary processing, self sealing, self welding,flanging and coil tube. Heat shrinkage ratio : 1.6 :1

Heat shrinkage temperature : 120℃~ 200℃

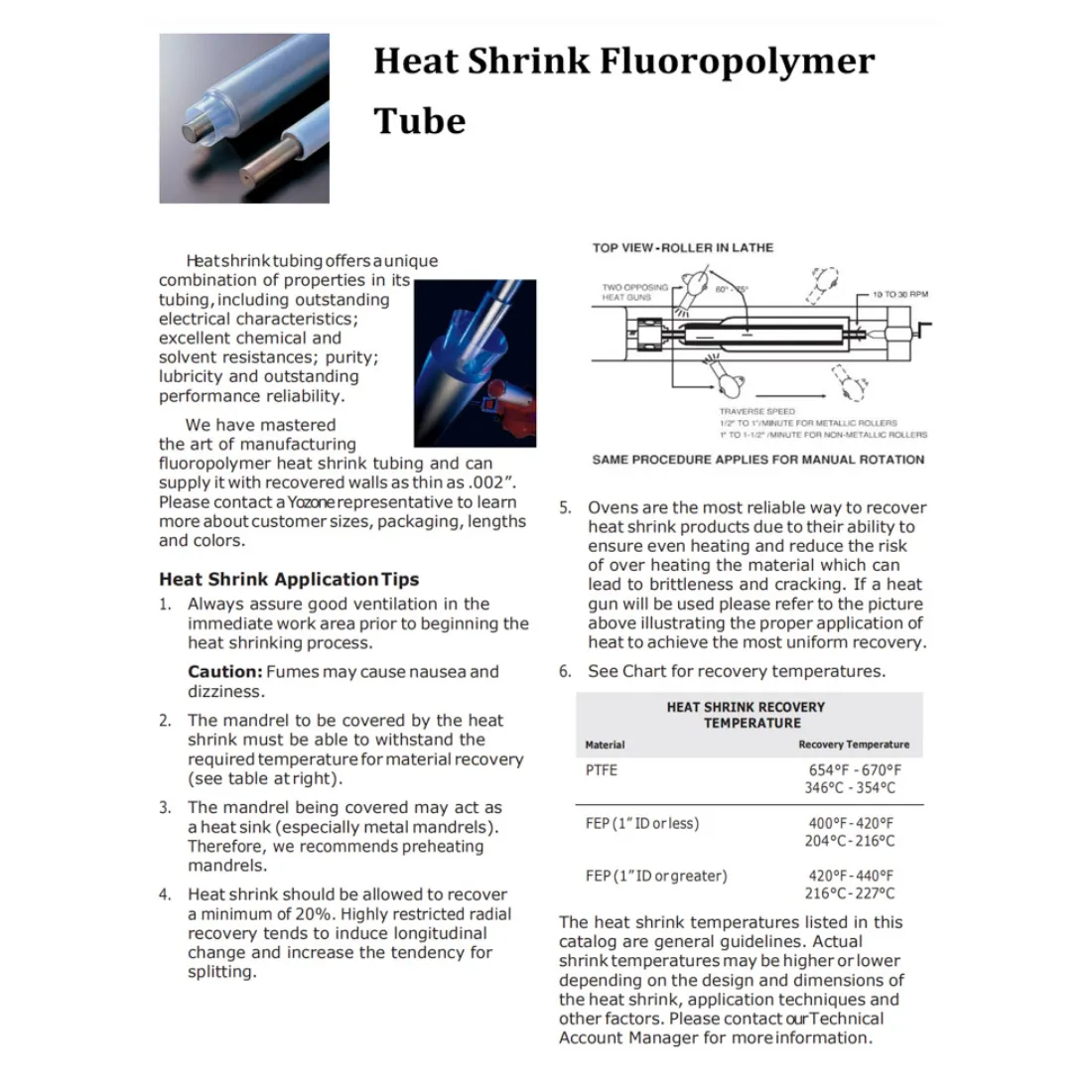

Heat shrink tubing Technical index

Index name unit Index value Density g/cm³ 2.12-2.18 Tensile strength Mpa ≥14 Elongation dt break % 175 Dielectric strength Mv/m 30 breakdown voitage Kv/mm ≥50

Our FEP heat shrinking tubing are crafted from pure high-molecular FEP material (Fluorinated Ethylene Propylene), ensuring exceptional stretch-ability and durability.

Heat shrink tubing manufacturers offer a range of 23 standard dimensions for our products, featuring diameters spanning from 0.68 mm to 200 mm. Our packaging options are customized to meet the specific requests of our customers. Additionally, we have the capability to produce these products in various colors upon request.

FEP Standard Heat Shrink Tube (mm)

max ID min ID Wall thick at min Wall tolerance(+/- mm)

0.78

0,68

0,20

0.03~0.05

0.91

0,81

0,20

0.03~0.05

1.14

0,99

0,20

0.03~0.05

1.52

1,24

0,20

0.03~0.05

1.60

1.10

0.25

0.03~0.05

1.90

1,55

0,23

0.03~0.05

2.00 1.50 0.30 0.03~0.05

2.50 1.90 0.20 0.03~0.05

3.60 2.70

0.20 0.03~0.05

4.20 3.00

0.50 0.03~0.05

4.80 3.60

0.27 0.03~0.05

5.00

4,00

0,28

0.03~0.05

5.70

4,57

0,28

0.03~0.05

6.20

4.60

0.30

0.03~0.05

7.36

5,75

0,28

0.03~0.05

7.85

6,33

0,28

0.03~0.05

8.00 6.00 0.30 0.03~0.05

9.50 7.00 0.50 0.03~0.05

12.00 9.00 0.50 0.03~0.05

13.50 10.00 0.50 0.03~0.05

15.00 11.00 0.50 0.03~0.05

18.00 13.00 0.50 0.03~0.05

19.00 14.00 0.50 0.03~0.05

22.00 16.00 0.50 0.03~0.05

25.00 19.00 0.50 0.03~0.05

31.00 23.00 0.50 0.03~0.05

36.00 27.00 0.50 0.03~0.05

43.00 32.00 0.50 0.03~0.05

54.00 40.00 0.50 0.03~0.05

62.00 46.00 0.50 0.03~0.05

76.00 56.00 0.50 0.03~0.05

85.00 65.00 0.50 0.03~0.05

96.00 80.00 0.50 0.03~0.05

105.00 95.00 0.50

0.03~0.05

110.00 95.00 0.50

0.03~0.05

115.00 95.00 0.50 0.03~0.05

130.00 107.00 1.50 0.03~0.05

150.00 113.00 0.70 0.03~0.05

FEP light heat shrink tube (mm)

max ID min ID wall thick at min Wall tolerance(+/- mm)

1.80 1.30 0.15 0.03~0.05 2.60 2.00 0.20 0.03~0.05 3.40 2.60 0.10 0.03~0.05 5.00 3.50 0.10 0.03~0.05 5.10 3.80 0.25 0.03~0.05 7.40 5.50 0.25 0.03~0.05 10.20 7.50 0.25 0.03~0.05 12.80 9.50 0.25 0.03~0.05 14.00 11.00 0.10 0.03~0.05 14.50 12.00 0.10 0.03~0.05 18.00 13.00 0.25 0.03~0.05 22.00 16.00 0.25 0.03~0.05 25.00 19.00 0.25 0.03~0.05 31.00 23.00 0.25 0.03~0.05 36.00 27.00 0.25 0.03~0.05 43.00 32.00 0.25 0.03~0.05 53.00 39.00 0.25 0.03~0.05 62.00 46.00 0.25 0.03~0.05

-

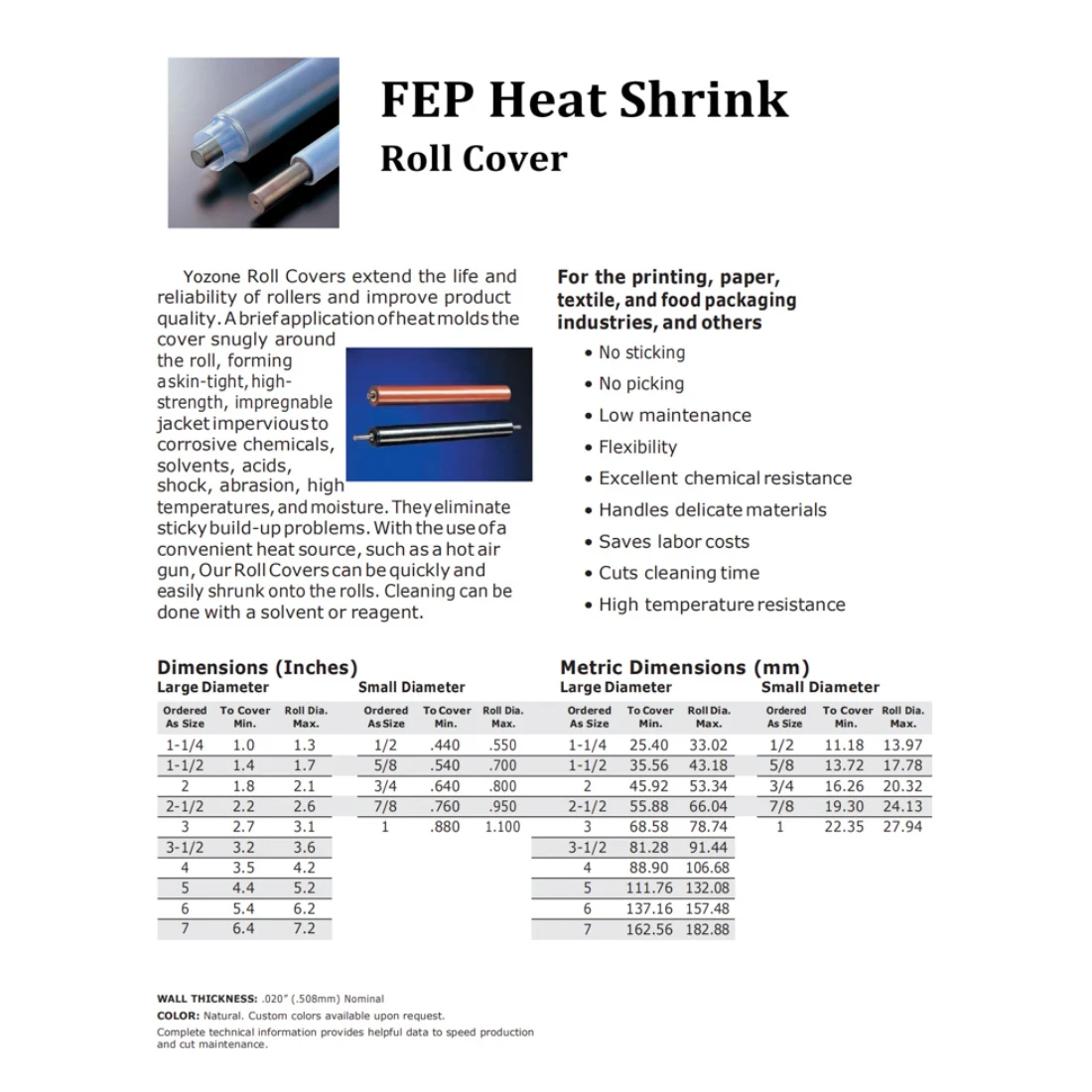

FEP Heat Shrinking Tube

YOZONE, as a leading manufacturer and supplier in the field of heat shrink tube production, always provides high quality heat shrink tube. Heat shrink tube is usually made of polymer materials such as polyolefin, which shrinks in diameter when heated and fits tightly to the object to which it is applied.

FEP heat shrinking tube are high-performance insulation materials designed for a variety of industrial and electrical applications. Known for their excellent chemical resistance, high-temperature tolerance, and electrical insulation properties, FEP heat shrinking tubes offer reliable protection for wires, cables, and other sensitive components.

FEP heat shrinking tube Key Features:

1.High Heat Resistance: FEP tubes can withstand temperatures up to 200°C (392°F), making them suitable for high-temperature applications.

2.Chemical Resistance: These tubes are highly resistant to acids, alkalis, and solvents, ensuring durability in harsh environments.

3.Excellent Electrical Insulation: FEP tubes provide superior insulation, preventing electrical leakage and ensuring safe operation.

4.Transparency: The tubes are transparent, allowing for easy inspection of the underlying components.

5.Flexible and Durable: FEP shrinking tubes are easy to apply and retain their strength, even under extreme conditions.

Characteristic Description Main Components Fluorinated Ethylene Propylene (FEP) polymer Temperature Resistance Range -200°C to 200°C (-328°F to 392°F) Chemical Resistance Acids, alkalis, organic solvents, and oils Electrical Insulation Advantages High dielectric strength, temperature stability, chemical resistance, non-flammability Shrink Ratio Typically 2:1 or 3:1 Applications of FEP Heat Shrinking Tubes

Industry Application Description Benefits Electronics Protecting and insulating wires and connections Enhanced safety and durability Automotive Insulating and bundling cables in vehicles Improved heat resistance and chemical durability Aerospace Providing insulation for wiring in aircraft systems Lightweight, reliable protection under extreme conditions Telecommunications Insulating connectors and bundling cables in telecom equipment Ensures signal integrity and environmental protection Medical Devices Protecting sensitive wiring in medical instruments High reliability and compliance with hygiene standards Industrial Equipment Insulating cables and protecting components in machinery Enhanced resistance to chemicals and mechanical wear Renewable Energy Insulating wiring in solar panels and wind turbines Durable protection against environmental factors What is the Lifespan of FEP Heat Shrinking Tubes?

FEP heat shrinking tubes are known for their long lifespan and durability. Under normal conditions, heat shrink tubing suppliers can last up to 20+ years. Their lifespan is largely determined by environmental factors such as temperature fluctuations, exposure to UV light, and chemical contact. In high-stress environments, like continuous high-temperature exposure or extreme chemical exposure, the lifespan may be shorter, but overall, FEP heat shrinking tubes are highly resistant to degradation, making them a reliable long-term solution.

What is the Shrinking Speed of FEP Heat Shrinking Tubes?

The shrinking speed of FEP heat shrink tubing is relatively fast compared to other materials.

Shrinking Speed of FEP Heat Shrinking Tubes

Characteristic

Description

Shrinking Speed

Starts shrinking within seconds of exposure to heat

Full Shrinkage Time

Typically takes 1-2 minutes to complete

Ideal Shrinkage Temperature

200°C to 250°C (392°F to 482°F)

Recommended Heat Source

Heat gun or oven

-

FEP100% Virgin Flexible Transparent Tubing OEM Manufacturer

Fep Shrink Tube Product Description

Yozonetech FEP tube are compliance with medical and industry standard, and it is also compliance with biocompatibility certificates.

The inner diameter of FEP pipe ranges from 0.2mm to 150mm,thus giving birth to wires and cables made of FEP.

Physical and Chemical Properties of FEP Tubing and Key Characteristics :

Yozonetech's FEP tubes comply with medical and industry standards, including biocompatibility certificates. With inner diameters spanning 0.2mm to 150mm, these extruded plastic tubes have given rise to FEP-based wires and cables.

Physical and Chemical Properties of FEP Tubing and Key Characteristics:

- Flexibility: FEP tubing offers enhanced flexibility over PTFE, broadening its applications.

- UV Resistance: FEP tubing resists UV aging, retaining properties despite prolonged UV exposure.

- Transparency: FEP tubing's high transparency aids fluid observation.

- Chemical Inertness: FEP tubing is exceptionally resistant to chemicals and corrosives.

- Dielectric Properties: FEP tubing's low dielectric constant suits electronic applications.

- Low Friction: FEP tubing's very low friction coefficient reduces fluid flow resistance.

- Melting Temperature: FEP tubing's lower melting temperature aids manufacturing.

- Anti-Stick: FEP tubing minimizes material adhesion with anti-stick properties.

- Temperature Range: FEP tubing operates within -200°C to +205°C.

- Non-Hygroscopic: FEP tubing's water absorption rate is <0.01%.

- FDA Approved: FEP tubing has FDA approval for food contact and more.

These attributes establish FEP tubing as a premier choice in sectors like chemistry, medicine, electronics, offering reliable solutions for diverse needs.

FEP tubing finds applications in:

- Chemical Industry: For corrosive liquids transfer and lining reaction vessels.

- Medical Devices: Favored for liquid transfer and bio-medical devices due to transparency and chemical resistance.

- Food Processing: Used in high food safety applications like food conveying pipelines.

- Electronics Sector: With electrical insulation properties, extruded plastic tubing is widely used in wire and cable insulation, electronic component encapsulation, and more.

Comparison with PTFE and PVC:

- Compared to PTFE: FEP tubing offers greater transparency than PTFE, suited for visually monitored applications. PTFE excels at extreme high temperatures but is less transparent.

- Compared to PVC: FEP tubing surpasses PVC in chemical resistance and high-temperature stability, suitable for demanding environments. PVC is easier to manufacture with lower costs but is less effective in high-temperature and corrosive media.

In summary, FEP tubing's unique attributes significantly benefit diverse sectors, and it's compared with PTFE and PVC within specific contexts.

[embed]https://youtu.be/L2O2-gid8bc[/embed]

[embed]https://youtu.be/Vz5y22nFZ6I[/embed]

[embed]https://youtu.be/wSMQesXHQKs[/embed]

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn