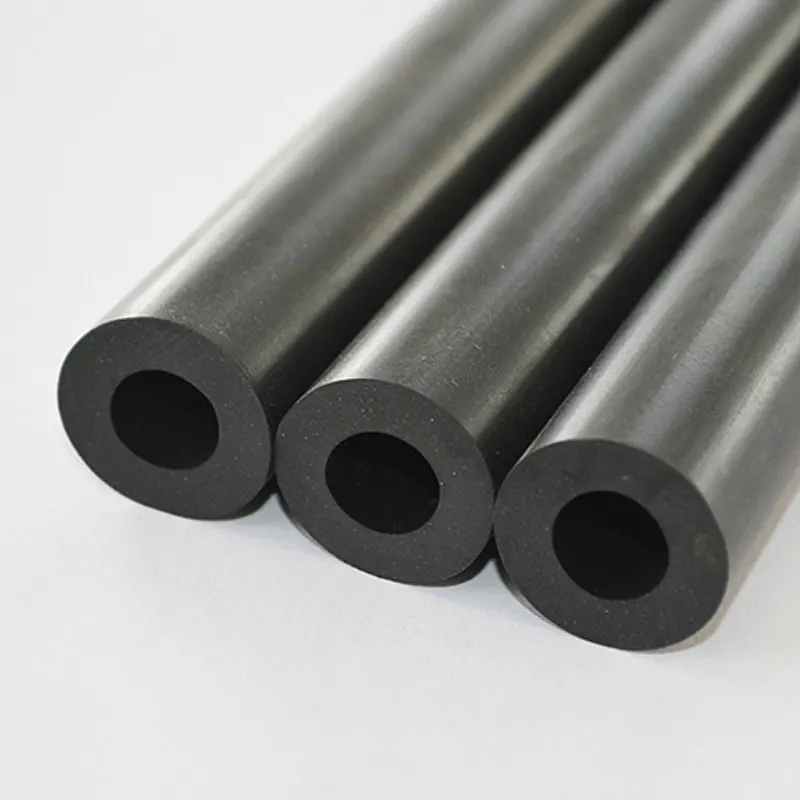

EPDM Injection Molding Part

EPDM injection molding Product Description

EPDM rubber sheet is a synthetic material. It is widely used in external applications due to its good aging resistance, ozone resistance, water resistance and resistance to harsh environmental conditions as an elastomer. The surface of the material is waterproof, has good abrasion resistance, and performs well when it comes in contact with chemicals such as lye, dilute acid and ketones. Common uses of EPDM include pipe seals, gaskets, rain strips and casings.

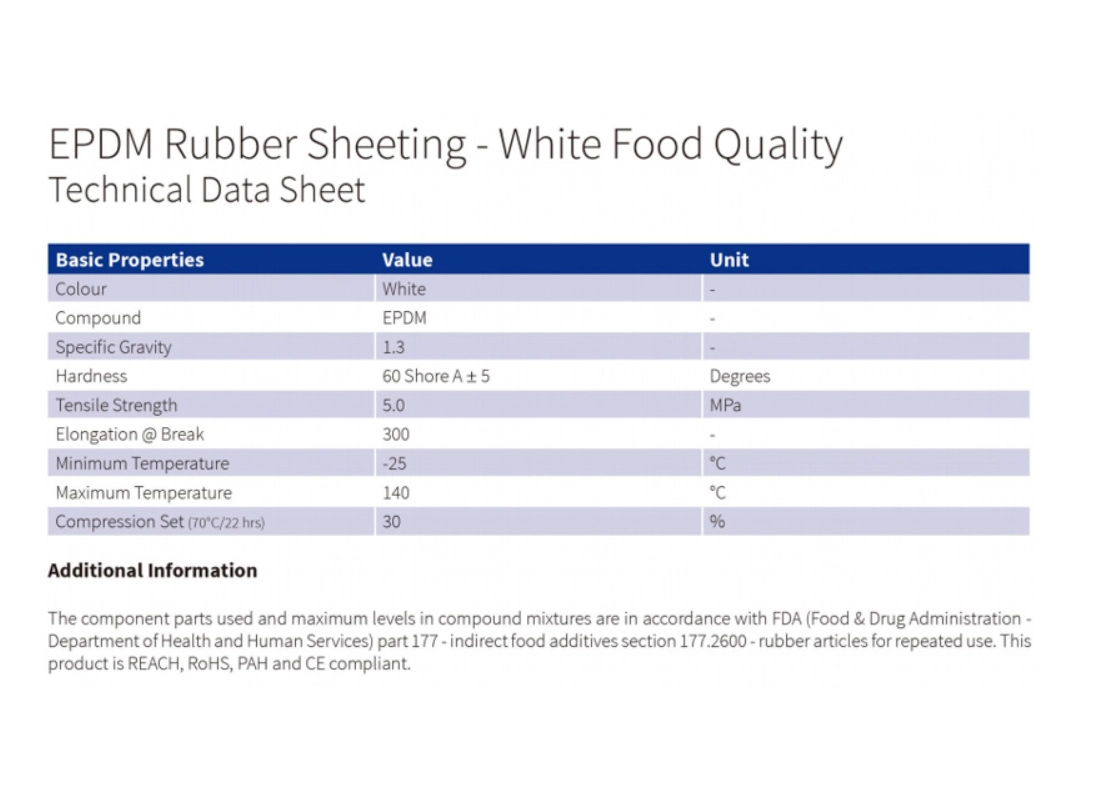

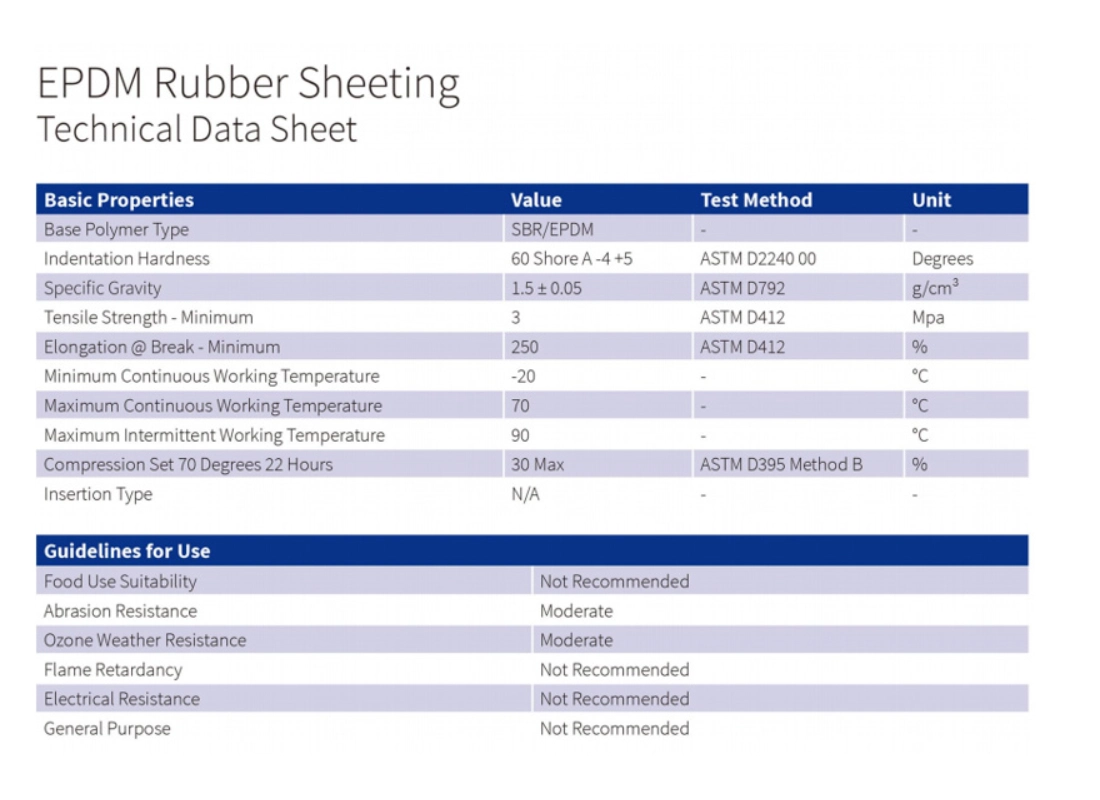

EPDM rubber sheets injection molding can be provided in rolls or cut into custom-sized parts using our in-house CNC machines. For applications requiring specific industrial characteristics, we can provide white food quality and WRAS/WRc approved grades. We also provide halogen-free flame-retardant EPDM dm engineer plastic products, which complies with the requirements of BS EN 45545-2:13 + A1:2015 and EN ISO 9239-1, and is approved as a material for railway vehicles.

EPDM injection molding Key Features

Shore Hardness: 60° ± 5°.

Temperature: -20°C up to +70°C (+90 °C intermittent).

Excellent resistance to ozone and weathering.

Good resistance to alkalines, diluted acids and ketones.

Commonly used in outdoor environments.

Extremely durable.

EPDM injection molding Product Specification

Place of Origin: China

Brand Name: YOZONE rubber injection molding supplier

Model Number: tsmcay-36

Pipe Material: 100% Virgin EPDM

Material brand: Daikin chemical, DuPont. Dongyue & Chenguang (Domestic)

Specification: Customized.

Length: Customized

Thickness: customized,

Shape: Round

Color: Black, customized

Working Temperature: -55 to +125°C (150°C after sulfur oxide)

Shore: 40A to 90A

Tolerance: ±0.05 mm

Electrical Property: Insulation Resistant

Certification: UL, CE, FDA, RoHS, REACH.

Standard: ISO9001:2008.

Test: SGS passed

Sample: Free

Payment: T/T

Service Life: Depends on environment, please kindly consult our engineers.

Application: Aerospace and electrical

EPDM injection molding Supply Ability:

100000 Pcs per Month EPDM Seals and Gaskets

EPDM injection molding Lead Time:

| Quantity(Kilograms) | 1 - 10 | 11 - 50 | 51 - 100 | >100 |

|---|---|---|---|---|

| Est. Time(days) | 3 | 5 | 7 | To be negotiated |

EPDM injection molding Packaging & Delivery

EPDM Seals and Gaskets into Carton and Wooden Pallet

Port: Tianjin, Shanghai, Shenzhen, Qingdao.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn