What is ETFE 100% Virgin Extruded Tube?

June 13, 2024

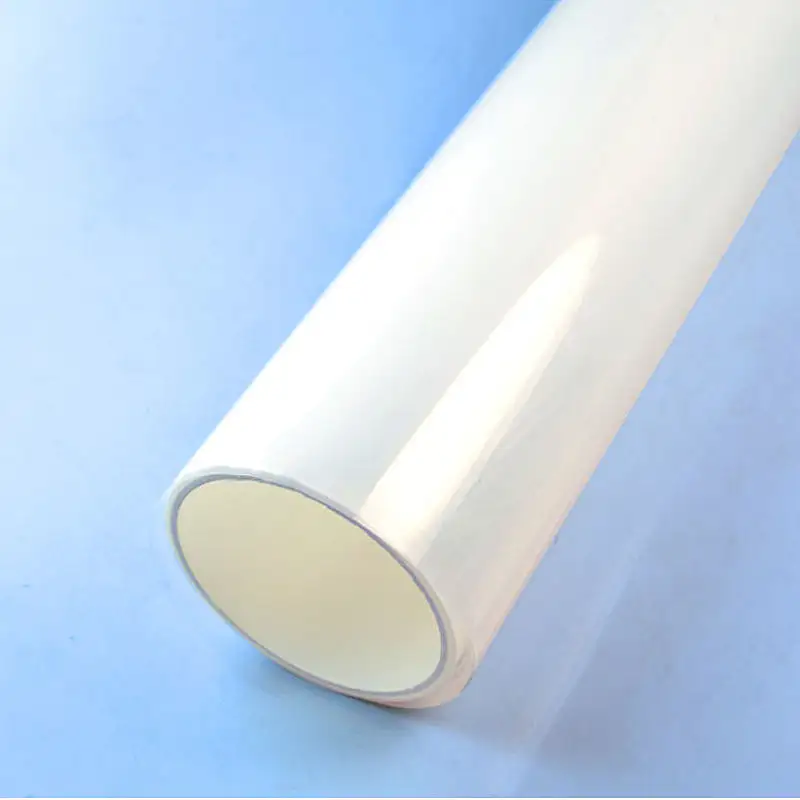

ETFE (Ethylene Tetrafluoroethylene) 100% Virgin Extruded Tube is an exemplary product recognized for its outstanding combination of transparency, strength, and resistance to harsh environmental conditions. This high-performance fluoropolymer tube offers a remarkable array of physical properties making it a preferred choice for numerous industrial applications, including but not limited to chemical processing, aerospace, and energy sectors.

Key Features:

1. Exceptional Chemical Resistance: ETFE 100% Virgin Extruded Tube provides unparalleled resistance to a wide range of chemicals, making it ideal for aggressive and corrosive environments where other materials would fail.

2. High-Temperature Tolerance: It can continuously operate in temperatures ranging from -76°F (-60°C) up to 302°F (150°C), and briefly up to 392°F (200°C), ensuring performance stability in challenging conditions.

3. Excellent Mechanical Strength: Despite its flexibility, ETFE tubing maintains superior tensile strength and durability, outperforming many other fluoropolymers under mechanical stress and high-pressure conditions.

4. Outstanding Electrical Properties: With its high insulation resistance and low dielectric constant, ETFE tubing is perfect for insulating wires and cables used in electrical and electronic applications.

5. UV and Radiation Resistance: ETFE tubes exhibit exceptional resistance to ultraviolet (UV) rays and gamma radiation, maintaining structural integrity and transparency even after prolonged exposure.

6. Transparency: ETFE’s natural transparency allows for visibility of flow, an essential feature for applications requiring flow monitoring.

Applications of ETFE 100% Virgin Extruded Tube :

– Chemical Processing: ETFE tubes are used extensively for conveying highly reactive and corrosive chemicals due to their exceptional chemical compatibility.

– Aerospace: In the aerospace industry, ETFE tubing is employed for hydraulic systems and fuel lines, offering lightweight solutions with excellent thermal and chemical resistance.

– Electrical & Electronics: Its superior electrical insulation properties make it suitable for protecting and insulating wires and cables in complex electronic systems.

– Architectural: Thanks to its excellent transparency and durability, ETFE tubing is also used in architectural applications, like covering structures, to provide UV protection without sacrificing natural light.

– Energy: In emerging energy technologies, including solar and fuel cells, ETFE tubing plays a crucial role due to its resistance to corrosive materials and temperatures.

Selection Guide:

When selecting ETFE 100% Virgin Extruded Tube for your application, consider the following:

– Diameter and Wall Thickness: Based on the fluid flow requirements and pressure conditions.

– Operating Environment: Ensure compatibility with chemical exposures and temperature ranges.

– Compliance and Certifications: Verify if specific industry standards or certifications are required for the application.

Conclusion:

ETFE 100% Virgin Extruded Tube is a versatile and robust solution for a wide range of industrial applications, offering a combination of durability, chemical resistance, and performance under extreme conditions. Its adoption across various sectors is a testament to its reliability and the unique advantages it brings to challenging industrial environments.

We are an ETFE 100% Virgin Extruded Tube supplier. Thanks to large-scale production, efficient supply chain management and low labor costs, China Viton 100% Pure Extruded Tube Factories are cost-effective while ensuring quality, making China Factory ETFE Tube highly competitive in the global market.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn