Fabricante OEM de tubo termorretráctil PVDF

PVDF heat shrink tubing Product Specifications:

Local de origem: China

Nome da marca: Yozonetech

Type: Insulator

Material:PVDF

Application:High Temperature

Rated Voltage:1kv

Tensile Strength:30MPA min

Product name:PVDF heat shrink tubing Kynar heat shrink tubes

Tensile strength:30 Mpa min

Operating temperature:-55 ~+150 °C

Elongation at break:150% min

Elongation at break after aging:100% min

Flammability:Flamable

shrink ratio:2:1

Supply Ability:10000 Meter/Meters per Day

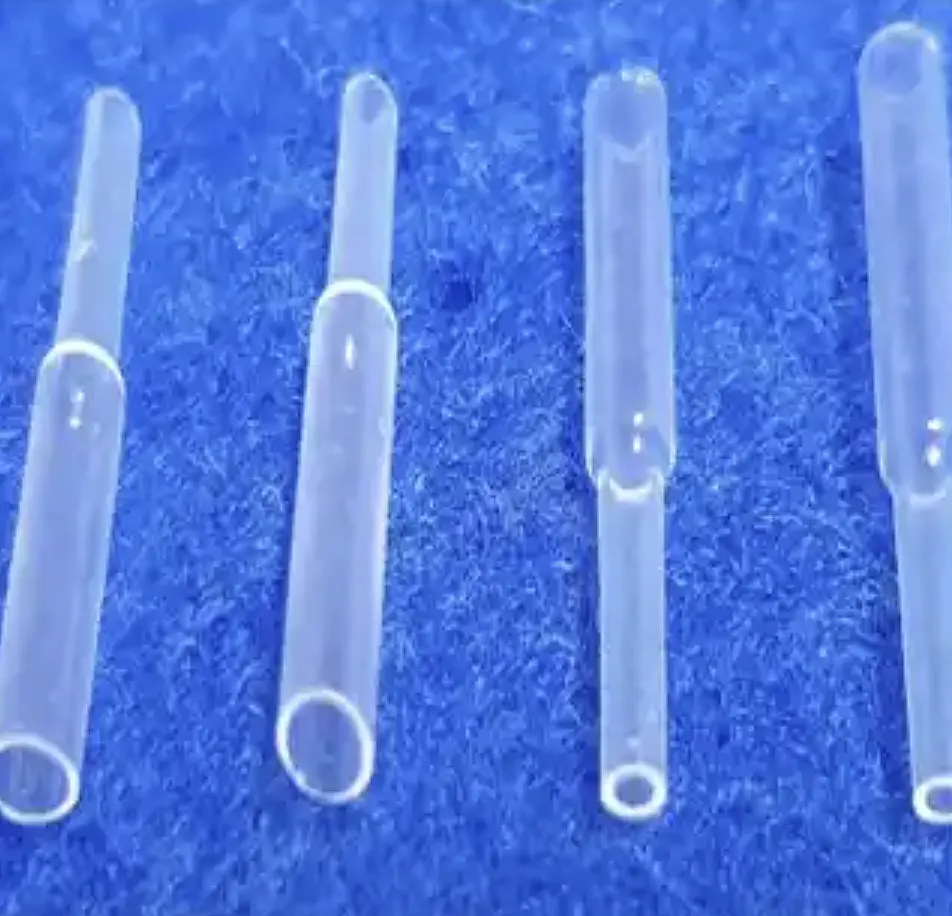

Polyvinylidene Fluoride (PVDF) is a thin-wall heat shrinkable tube made from radiation-modified polyvinylidene fluoride. It is transparent, flame retardant, resistant to high temperatures, most oils, and chemicals, as well as being durable and cut-resistant. It is widely used for protecting welding points, terminals, and connecting cables that are exposed to high temperatures, industrial fuels, solvents, and chemical agents.

PVDF heat shrink tubing Product Features:

Shrink Ratio: 2:1

Minimum Shrink Temperature: ≥+135℃

Operating Temperature: -55℃ to +150℃

Flexible, corrosion-resistant, abrasion-resistant, and cut-resistant Environmental Standard: RoHS

Standard Colors: Transparent, Black.

| Desempenho | Desempenho | Índice | Método de ensaio |

|---|---|---|---|

| Physical Performance | Tamanho | Personalizado | ASTM D 2671 |

| Longitudinal Length Change | -10%~+5% | ASTM D 2671 | |

| Resistência à tração | ≥24.1 MPa | ASTM D 2671 | |

| Alongamento na rutura | ≥300% | ASTM D 2671 | |

| Rácio de retração | ≤40% | AMS-DTL-23053 | |

| Tangent Modulus | ≥172 MPa | ASTM D 2671 | |

| Densidade | ≤1.9 g/cm3 | ASTM D 2671 | |

| Low-Temperature Flexibility | No Cracks | AMS-DTL-23053(-55℃×4h) | |

| Thermal Shock | No Dripping, No Flowing, No Cracks | ASTM D 2671(250℃×4h) | |

| Tensile Strength after Heat Aging | ≥19.1 MPa | ASTM D 2671(225℃×168h) | |

| Elongation at Break after Heat Aging | ≥200% | ASTM D 2671(225℃×168h) | |

| Transparency StabilityIdentification | Markings Still Clear | AMS-DTL-23053(200℃×24h) | |

| Electrical Insulation Performance | Resistência dieléctrica | ≥15.7kV/mm | ASTM D 2671 |

| Volume Resistivity | ≥1012Ω ·cm | ASTM D 2671 | |

| Chemical Performance | Copper Corrosion | No Corrosion | ASTM D 2671(160℃×16h) |

| Flame Retardant | Self-extinguishing within 60s, Paper Flag Burning Degree | UL224 VW-1, ASTM D 2671 C法 |

|

| Water Absorption | ≤0.5% | ISO 846 B法, 23℃×24h | |

| Tensile Strength after Fungus Resistance | ≥24.1 MPa | ASTM D 2671 | |

| Elongation at Break after Fungus Resistance | ≥300% | ASTM D 2671 | |

| Dielectric Strength after Fungus Resistance | ≥15.7kV/mm | ASTM D 2671 | |

| Tensile Strength after Chemical Resistance | ≥13.8 MPa | ASTM D 2671 | |

| Elongation at Break after Chemical Resistance | ≥200% | ASTM D 2671 | |

| Dielectric Strength after Chemical Resistance | ≥15.7kV/mm | ASTM D 2671 |

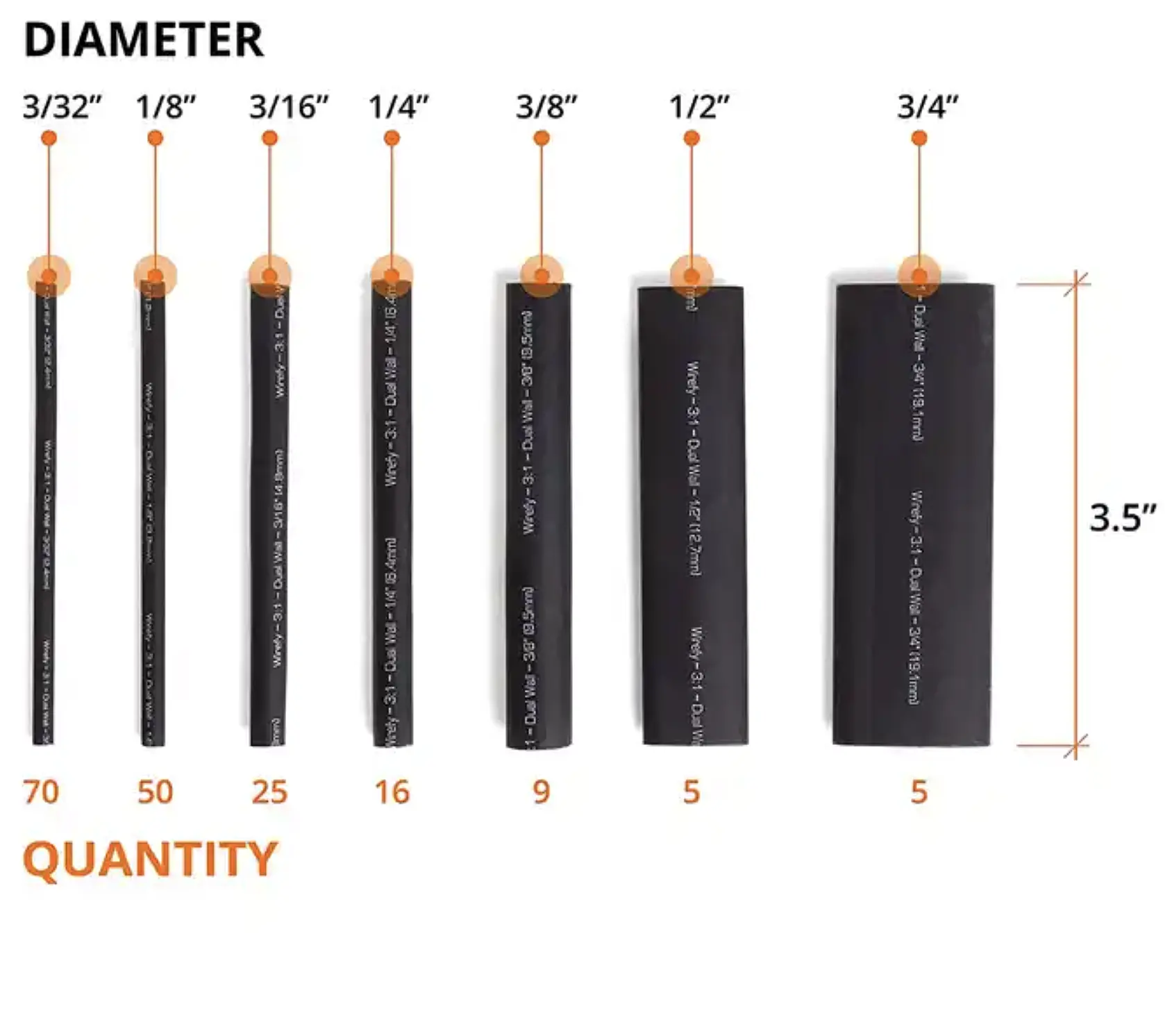

| Tamanho | Product ID (mm) | Size after shrinking (mm) | Shape | Package m/roll | ||

|---|---|---|---|---|---|---|

| Inch | mm | ID | Espessura da parede | |||

| 1/32 | Φ0.8 | ≥0.8 | ≤0.5 | 0.30±0. 10 | Redondo | 200 |

| 3/64 | Φ1.2 | ≥ 1.2 | ≤0.6 | 0.33±0. 10 | Redondo | 200 |

| 1/ 16 | Φ1.6 | ≥ 1.6 | ≤0.8 | 0.33±0. 10 | Redondo | 200 |

| 3/32 | Φ2.4 | ≥2.4 | ≤ 1.2 | 0.33±0. 10 | Redondo | 200 |

| 1/8 | Φ3.2 | ≥3.2 | ≤ 1.6 | 0.35±0. 10 | Redondo | 100 |

| 3/ 16 | Φ4.8 | ≥4.8 | ≤2.4 | 0.35±0. 10 | Redondo | 100 |

| 1/4 | Φ6.4 | ≥6.4 | ≤3.2 | 0.35±0. 10 | Flat | 100 |

| 3/8 | Φ9.5 | ≥9.5 | ≤4.8 | 0.38±0. 10 | Flat | 50 |

| 1/2 | Φ12.7 | ≥ 12.7 | ≤6.4 | 0.38±0. 10 | Flat | 50 |

| 5/8 | Φ15.0 | ≥ 15.0 | ≤7.5 | 0.40±0. 10 | Flat | 50 |

| 3/4 | Φ19. 1 | ≥ 19. 1 | ≤9.5 | 0.42±0. 10 | Flat | 50 |

| 1 | Φ25.4 | ≥25.4 | ≤ 12.7 | 0.42±0. 10 | Flat | 50 |

| 1- 1/2 | Φ38. 1 | ≥38. 1 | ≤ 19. 1 | 0.48±0. 10 | Flat | 50 |

175ºC PVDF heat shrink tube

Product Introduction: The 175℃ Polyvinylidene Fluoride Tubo termo-retrátil is made from radiation-modified polyvinylidene fluoride, offering transparency, flame retardancy, high-temperature resistance, resistance to most oils and chemicals, as well as durability and cut-resistant properties. Tubos termorretrácteis personalizados finds extensive applications in protecting welding points, terminals, and connecting cables that fabricantes de tubos termorretrácteis are exposed to high temperatures, industrial fuels, solvents, and chemical agents.

PVDF heat shrink tubing Product Features:

Shrink Ratio: 2:1 Minimum Shrink

Temperature: ≥+175℃

Operating Temperature: -55℃ to +175℃

Flexible, corrosion-resistant, abrasion-resistant, and cut-resistant

Environmental Standard: RoHS

Standard Colors: Transparent, Black.

| Desempenho | Performance Index | Método de ensaio |

|---|---|---|

| Densidade | 1.78 g/cm³ | ASTM D791 |

| Resistência à tração | ≥30 MPa | ASTM D2671 |

| Alongamento na rutura | ≥ 150% | ASTM D2671 |

| Elongation at Break after Aging | ≥ 100% | 250C×168h |

| Volume Resistivity | ≥ 1014 Ω•cm | IEC 60093 |

| Flame Retardant | VW- 1 | UL224 |

| Cold Bend Flexibility | No cracks | -55C×4h |

| Thermal Shock | No cracks | 250C×4h |

| Copper Corrosion | No corrosion | 180C×168h |

| Copper Stabilization | Copper Stabilization | 180C×168h |

| Tamanho | Product size (mm) | Size after shrinking (mm) | Shape | Package m/roll | ||

|---|---|---|---|---|---|---|

| Inch | mm | ID | Espessura da parede | |||

| 3/64 | Φ1.2 | ≥ 1.2 | ≤ 0.6 | 0.33±0. 10 | Redondo | 200 |

| 1/ 16 | Φ1.6 | ≥ 1.6 | ≤ 0.8 | 0.33±0. 10 | Redondo | 200 |

| 3/32 | Φ2.4 | ≥ 2.4 | ≤ 1.2 | 0.33±0. 10 | Redondo | 200 |

| 1/8 | Φ3.2 | ≥ 3.2 | ≤ 1.6 | 0.35±0. 10 | Redondo | 100 |

| 3/ 16 | Φ4.8 | ≥ 4.8 | ≤ 2.4 | 0.35±0. 10 | Redondo | 100 |

| 1/4 | Φ6.4 | ≥ 6.4 | ≤ 3.2 | 0.35±0. 10 | Flat | 100 |

| 3/8 | Φ9.5 | ≥ 9.5 | ≤ 4.8 | 0.38±0. 10 | Flat | 50 |

| 1/2 | Φ12.7 | ≥ 12.7 | ≤ 6.4 | 0.38±0. 10 | Flat | 50 |

| 5/8 | Φ15.0 | ≥ 15.0 | ≤ 7.5 | 0.40±0. 10 | Flat | 50 |

| 3/4 | Φ19.1 | ≥ 19.1 | ≤ 9.5 | 0.42±0. 10 | Flat | 50 |

| 1 | Φ25.4 | ≥ 25.4 | ≤ 12.7 | 0.42±0. 10 | Flat | 50 |

| 1- 1/2 | Φ38.1 | ≥ 38.1 | ≤ 19.1 | 0.48±0. 10 | Flat | 50 |

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn