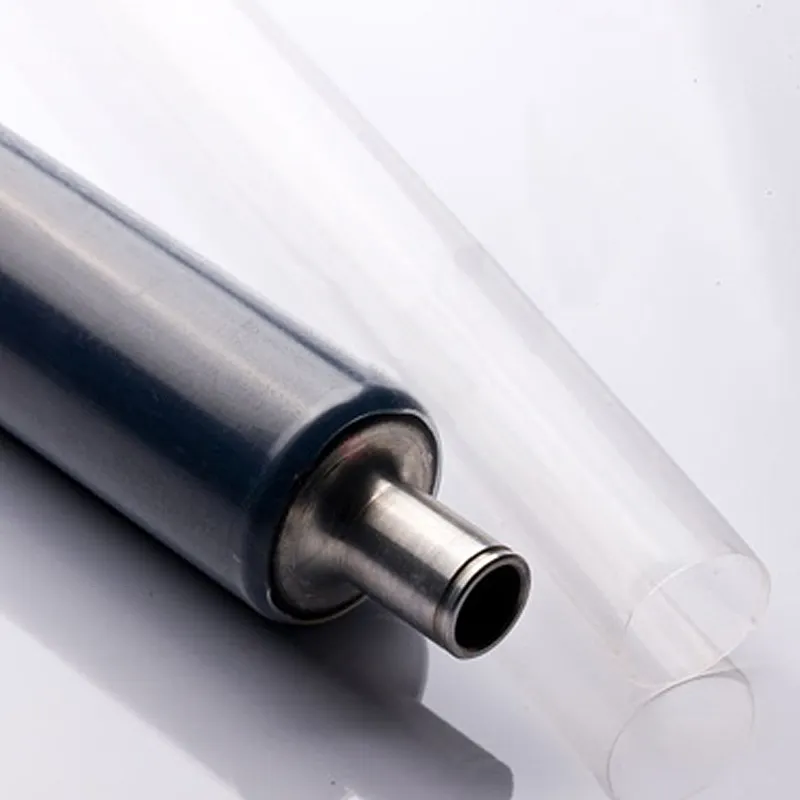

tubos termorretrácteis fep

-

Fabricante OEM de tubos termorretráteis personalizados de ETFE

Os melhores tubos termorretrácteis Descrição do Produto:

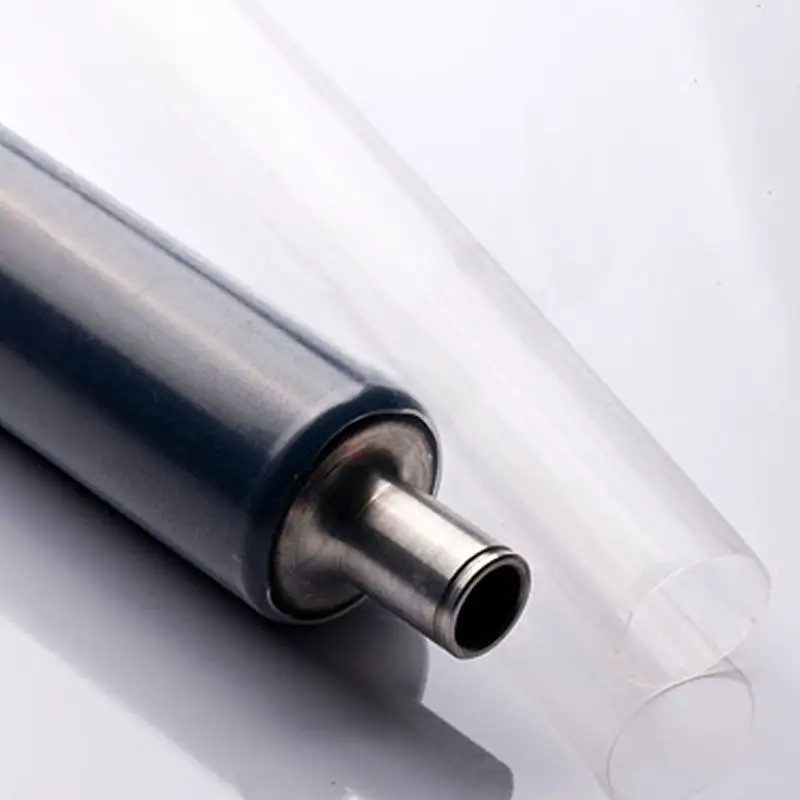

Os nossos FEP e ETFE de elevada retração são normalmente utilizados como camada de libertação na indústria de compósitos para aviação. O fluoropolímero retrátil tubos termorretrácteis à prova de água é uma solução perfeita como anel de vedação cheio de gás de fibra de carbono ou fibra de vidro. O tubo retrátil FEP tem uma excelente resistência a altas temperaturas e pode suportar temperaturas de cura até 256°C.

Devido à composição química do ETFE, é também uma excelente barreira dieléctrica e barreira química. As caraterísticas de retração da película fazem com que se adapte à estrutura original, o que é fácil de utilizar e manter. Tubos termo-retrácteis torna-o uma excelente solução para aplicações de baterias e canais de arrefecimento em componentes electrónicos.

Os melhores tubos termorretrácteis Especificação do produto:

Local de origem: China

Nome da marca: YOZONE fornecedores de tubos termorretrácteis

Marca do material: Daikin Chemical, DuPont. Dongyue & Chenguang (nacional)

Comprimento: Personalizado

Forma: Redondo

Cor: Branco, personalizado.

Temperatura de funcionamento: -200°C - +150°C

Tolerância: ±0,05 mm

Resistência química: estável na maioria dos meios.

Propriedade eléctrica: Resistente ao isolamento

Certificação: UL, CE, FDA, RoHS, REACH.

Norma: ISO9001:2008.

Teste: Aprovado pela SGS

Amostra: Grátis

Pagamento: T/T

Vida útil: Depende do ambiente, por favor consulte os nossos engenheiros.

Aplicações: Transporte de petróleo, processamento de alimentos, eletricidade, etc.

Os melhores tubos termorretrácteis Capacidade de fornecimento:

100000 metros/metros por mês de tubo termorretrátil de ETFE

Os melhores tubos termorretrácteis Prazo de entrega:

Quantidade (quilogramas) 1 - 10 11 - 50 51 - 100 >100 Est. Tempo (dias) 3 5 7 A ser negociado

Os melhores tubos termorretrácteis Embalagem e entrega

Tubo termorretrátil de ETFE em caixa de papelão e palete de madeira

Porto: Tianjin, Shanghai, Shenzhen, Qingdao.

-

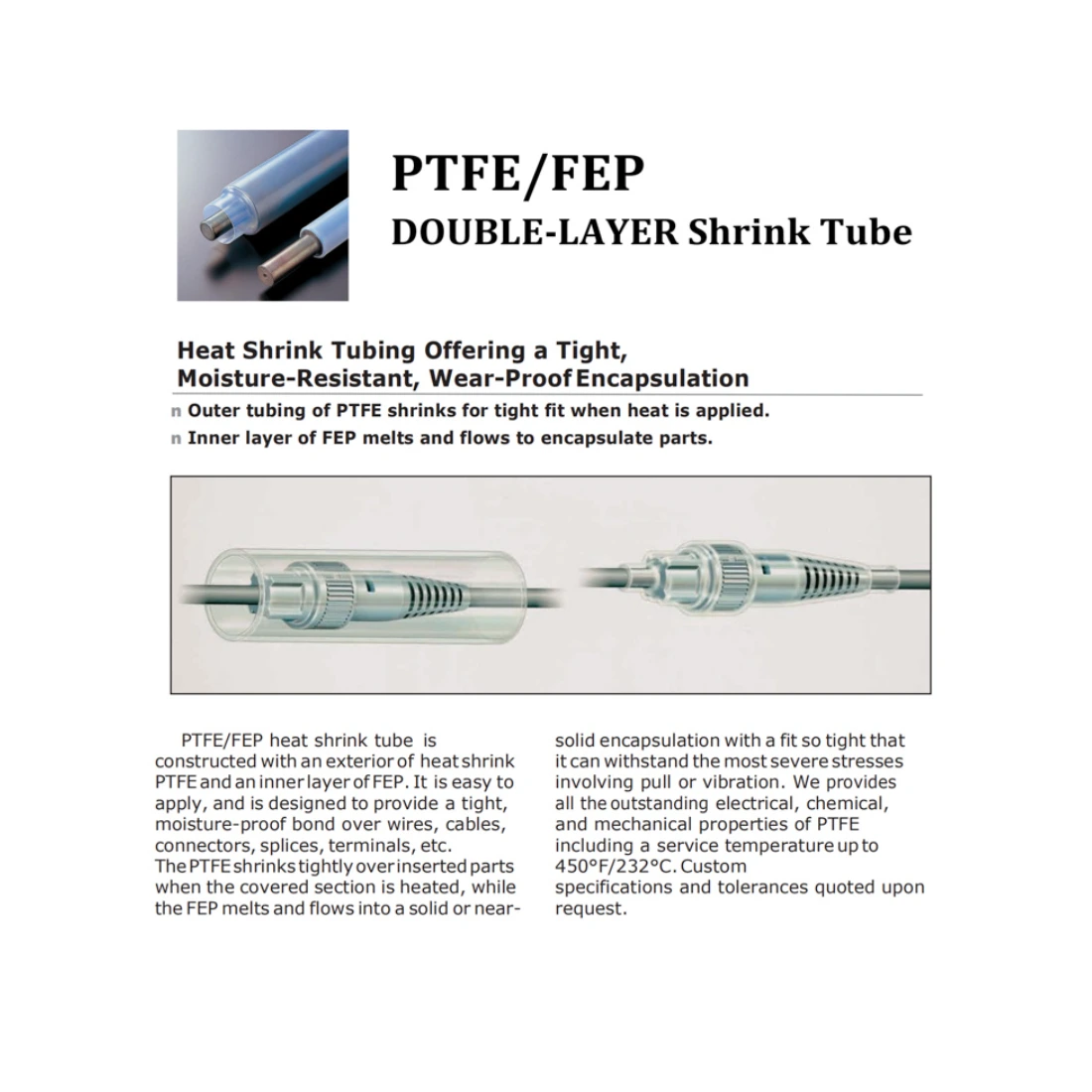

Tubo termorretráctil destacável FEP de grau médico com certificação de bio-compatibilidade

Tubos termorretrácteis para uso médico Desempenho e utilização:

Poliper fluoroetileno propileno FEP médico destacável tubos termorretrácteis tem excelentes propriedades de isolamento elétrico e resistência a altas temperaturas, e é utilizado em

Componentes que precisam de ser expostos a ambientes de alta temperatura e têm requisitos de isolamento elevados durante o processo. Tem uma excelente resistência a líquidos e

Corrosivo, fisiologicamente inerte, pode estar em contacto direto com a pele humana, utilizado principalmente em instrumentos médicos cirúrgicos e componentes e equipamentos médicos.

Tubos termorretrácteis para uso médico Caraterísticas:

Rácio de retração: 1,3:1

Temperatura de trabalho: -55℃~200℃

Temperatura de retração inicial: ≥150℃

boa transparência

Excelentes propriedades de isolamento elétrico e inércia fisiológica

Reúne óxido de etileno (ETO), esterilização gama

Fabricantes de tubos termorretrácteis Em conformidade com a norma ISO 10993-1

Tubos termorretrácteis personalizados Normas ambientais: sem metais pesados, em conformidade com a diretiva ROHS

Cor padrão: transparente

Tubos termorretrácteis para uso médico Especificação

Não.

Tamanho

ID antes do encolhimento (mm)

ID após encolhimento (mm)

Parede após retração (mm)

1

XMC-FEP φ1,2mm

>1.20

<0.70

0.20±0.05

2

XMC-FEP φ2,5mm

>2.50

<1.80

0.20±0.05

3

XMC-FEP φ2,8mm

>2.80

<2.10

0.25±0.05

4

XMC-FEP φ3,1mm

>3.10

<2.20

0.25±0.05

5

XMC-FEP φ4,7mm

>4.70

<2.90

0.25±0.05

Tubos termorretrácteis para uso médico Indicadores técnicos

Item

Método de ensaio

Dados típicos

Resistência à tração (Mpa)

ASTM D 638

≥13,8Mpa

Alongamento na rutura

ASTM D 638

≥300%

Taxa de variação da contração axial

ASTM D 2671

±10%

Rigidez dieléctrica (kV/mm)

ASTM D 2671

≥19.70

Tensão suportável de isolamento

ASTM D 149

4000V, sem avaria nos anos 60

Resistividade volumétrica

UL 224

≥101*Ω.cm

Flexibilidade a baixas temperaturas

AMS-DTL-23053

65℃/4 horas, sem fissuras

Corrosão do cobre

AMS-DTL-23053

Sem amolgadelas ou escurecimento

clareza estabilidade

AMS-DTL-23053

passar

Retardador de chama

ASTM D 2671C法

Auto-extinção em 15s

-

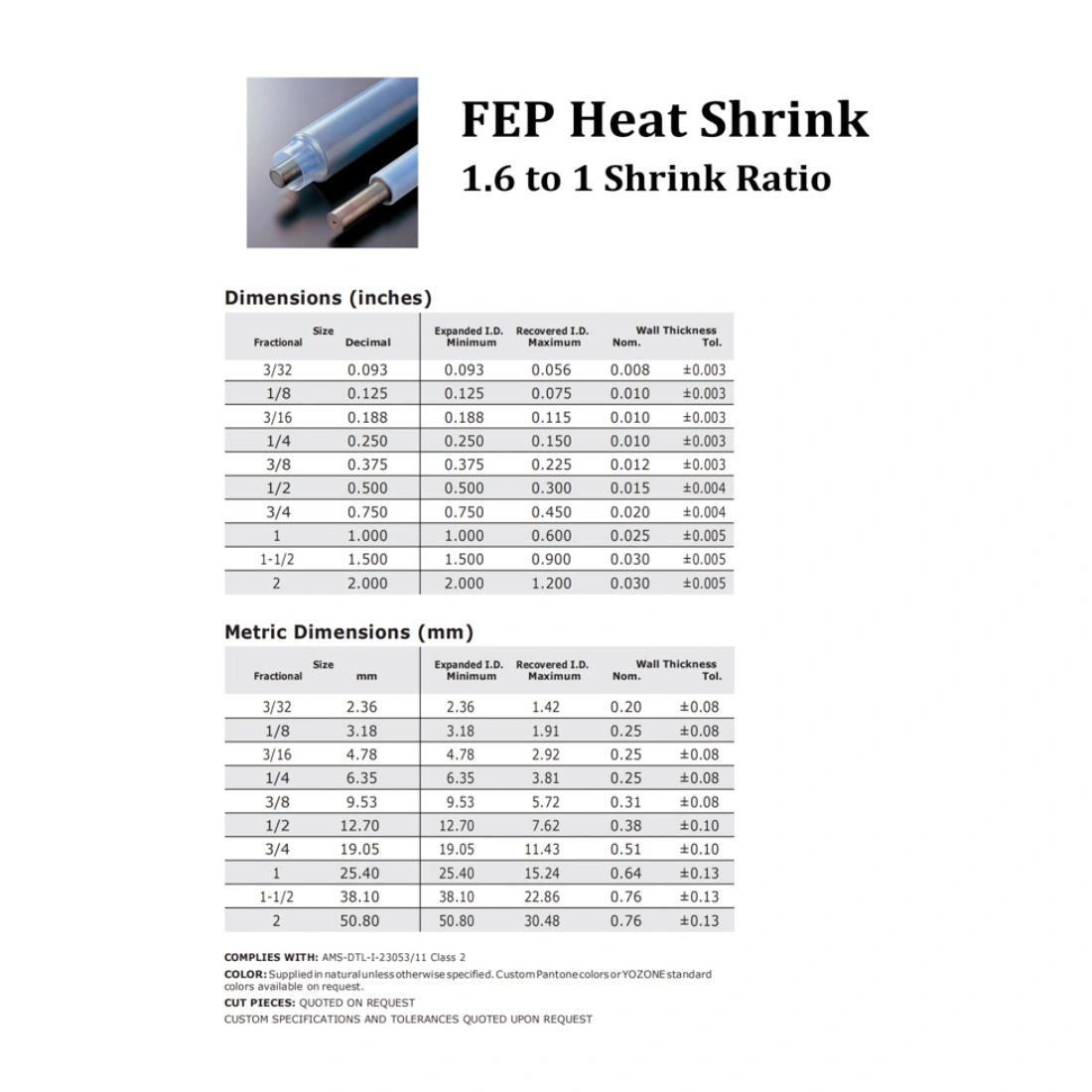

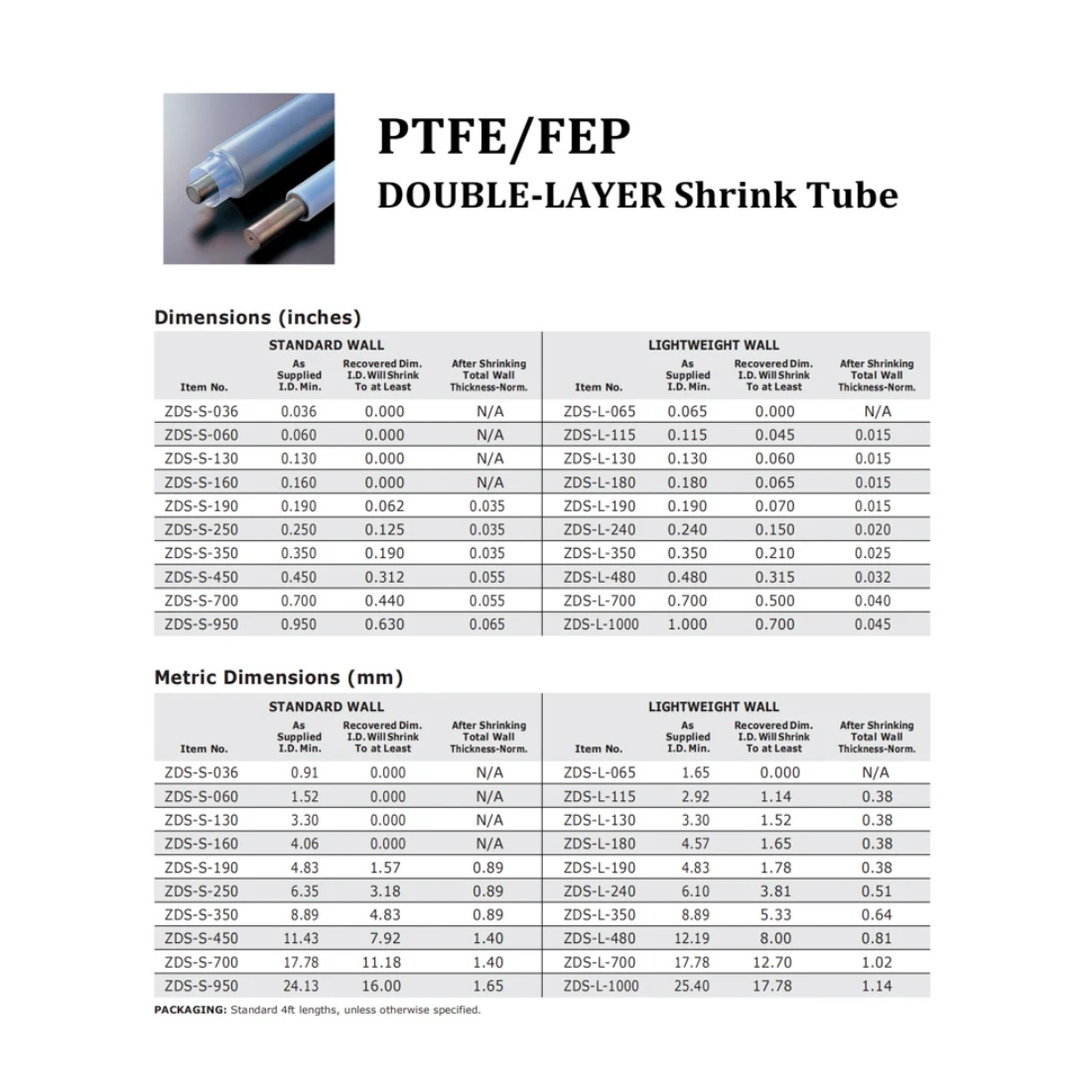

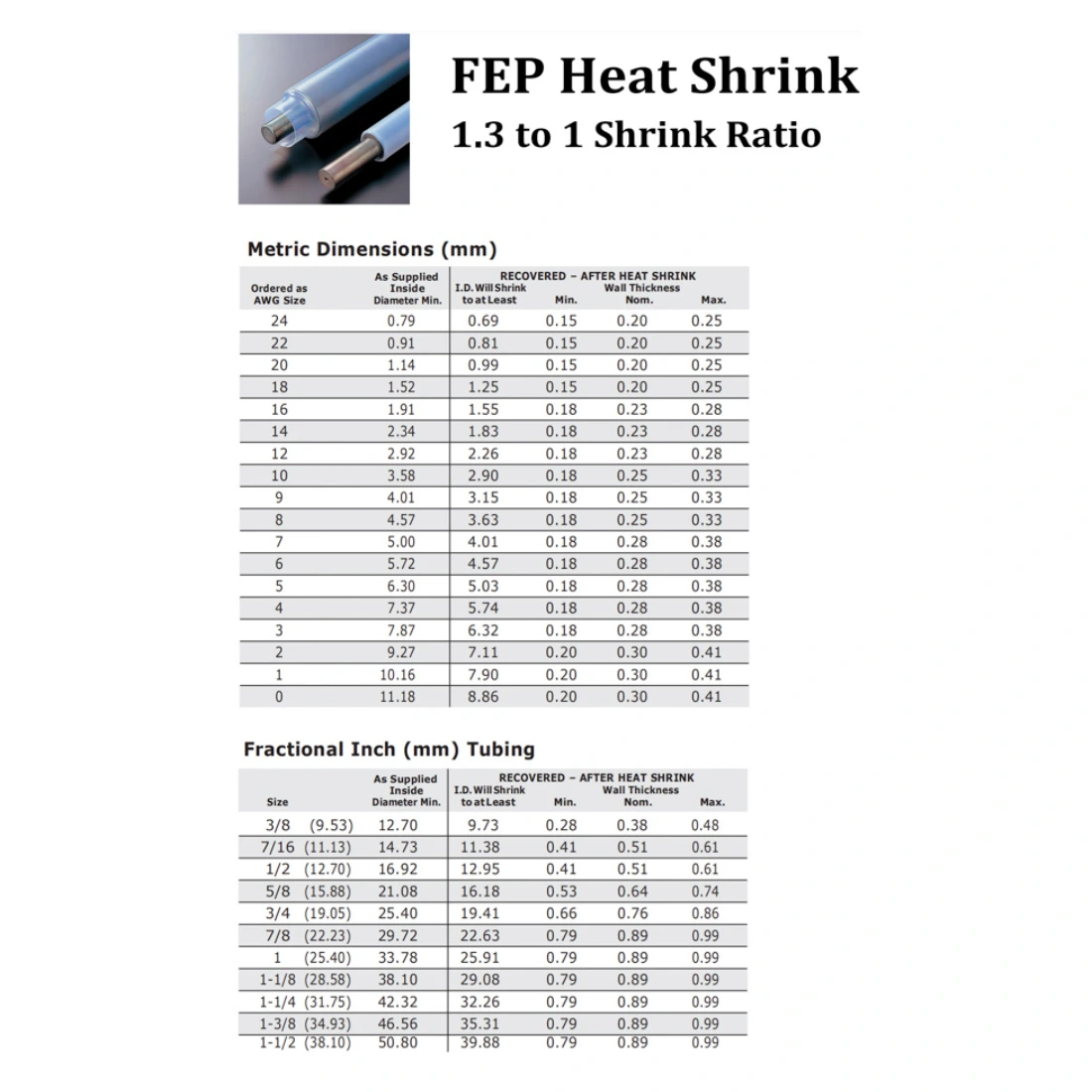

Isolamento FEP Anti-Uv 1.6:1 1.3:1 Diâmetro de retração térmica 1-150mm mangas de tubagem

Tubo termo-retrátil Descrição do produto

As propriedades do copolímero FEP são semelhantes às do PTEE, mas sua resistência ao calor é ligeiramente menor, e pode funcionar a 85 ℃ + 205 ℃ por um longo tempo, e a - 200 ℃ + 300 ℃ por um curto período de tempo; tem alta resistência ao impacto, resistência à fluência e flexibilidade de baixa temperatura, que é melhor do que PTEE; sua cristalinidade é diferente com a temperatura do tratamento térmico, e sua capacidade de processo de moldagem é boa; é não tóxico, não pegajoso, isolamento elétrico, resistência ao desgaste e estabilidade química são melhores que o PTEE Possui excelente resistência a altas e baixas temperaturas, resistência ao óleo e resistência a reagentes químicos. É utilizado principalmente para a bainha de isolamento de equipamento mecânico, equipamento médico, equipamento de comunicação, indústria química, indústria automóvel, isolamento principal do rotor do motor, tratamento de água, revestimento do tambor do rolo no campo petrolífero.

[embed]https://youtu.be/-hgILz2qbT4[/embed]

[embed]https://youtu.be/Z_qx0oQW3R8[/embed]

Tubos termorretrácteis FEP para uso médico Caraterísticas do produto

Resistência à corrosão: apenas o flúor e os metais alcalinos desempenham um papel nesta resistência a altas temperaturas e não têm qualquer efeito em todos os outros ácidos orgânicos inorgânicos, bases e ésteres.

Resistência a altas e baixas temperaturas: - 85 ℃ a 200 ℃ de alta temperatura

Baixa absorção de água: baixa absorção de água < 0,01%

Incombustibilidade : não há combustão no ar (índice de oxigénio > 95 vo.%)

Não tóxico: inércia fisiológica

Elevada transparência: baixo índice de refração no plástico

Antiaderente: hidrofóbico, repelente de óleo

Propriedade elétrica: alto isolamento: a viscosidade constante dielétrica de 60hz- 60mhz em alta e baixa temperatura é 2.1. Mesmo se a superfície for danificada por mergulho, não haverá trilha condutora. resistência de volume> 1018 Q m, resistência de superfície> 1013 Q, resistência de arco 》165S Sem vazamento de eletricidade

Baixo atrito: coeficiente de atrito dinâmico 0,2-0,3

Maquinabilidade: fácil para processamento secundário, auto-selagem, auto-soldadura, flangeamento e tubo de bobina. Rácio de retração térmica: 1,6 :1

Temperatura de encolhimento de calor: 120 ℃ ~ 200 ℃

Tubo termo-retrátil Índice técnico

Nome do índice unidade Valor do índice Densidade g/cm³ 2.12-2.18 Resistência à tração Mpa ≥14 Alongamento dt rutura % 175 Resistência dieléctrica Mv/m 30 avaria voitage Kv/mm ≥50

O nosso FEP tubos termo-retrácteis são fabricadas a partir de material FEP (Etileno Propileno Fluorado) puro de elevado peso molecular, garantindo uma capacidade de estiramento e uma durabilidade excepcionais.

Fabricantes de tubos termorretrácteis oferecemos uma gama de 23 dimensões padrão para os nossos produtos, com diâmetros que vão de 0,68 mm a 200 mm. As nossas opções de embalagem são personalizadas para satisfazer os pedidos específicos dos nossos clientes. Para além disso, temos a capacidade de produzir estes produtos em várias cores, mediante pedido.

Tubo termorretráctil padrão FEP (mm)

ID máximo ID mínimo Espessura da parede no mínimo Tolerância da parede (+/- mm)

0.78

0,68

0,20

0.03~0.05

0.91

0,81

0,20

0.03~0.05

1.14

0,99

0,20

0.03~0.05

1.52

1,24

0,20

0.03~0.05

1.60

1.10

0.25

0.03~0.05

1.90

1,55

0,23

0.03~0.05

2.00 1.50 0.30 0.03~0.05

2.50 1.90 0.20 0.03~0.05

3.60 2.70

0.20 0.03~0.05

4.20 3.00

0.50 0.03~0.05

4.80 3.60

0.27 0.03~0.05

5.00

4,00

0,28

0.03~0.05

5.70

4,57

0,28

0.03~0.05

6.20

4.60

0.30

0.03~0.05

7.36

5,75

0,28

0.03~0.05

7.85

6,33

0,28

0.03~0.05

8.00 6.00 0.30 0.03~0.05

9.50 7.00 0.50 0.03~0.05

12.00 9.00 0.50 0.03~0.05

13.50 10.00 0.50 0.03~0.05

15.00 11.00 0.50 0.03~0.05

18.00 13.00 0.50 0.03~0.05

19.00 14.00 0.50 0.03~0.05

22.00 16.00 0.50 0.03~0.05

25.00 19.00 0.50 0.03~0.05

31.00 23.00 0.50 0.03~0.05

36.00 27.00 0.50 0.03~0.05

43.00 32.00 0.50 0.03~0.05

54.00 40.00 0.50 0.03~0.05

62.00 46.00 0.50 0.03~0.05

76.00 56.00 0.50 0.03~0.05

85.00 65.00 0.50 0.03~0.05

96.00 80.00 0.50 0.03~0.05

105.00 95.00 0.50

0.03~0.05

110.00 95.00 0.50

0.03~0.05

115.00 95.00 0.50 0.03~0.05

130.00 107.00 1.50 0.03~0.05

150.00 113.00 0.70 0.03~0.05

Tubo termorretráctil leve FEP (mm)

ID máximo ID mínimo espessura da parede no mínimo Tolerância da parede (+/- mm)

1.80 1.30 0.15 0.03~0.05 2.60 2.00 0.20 0.03~0.05 3.40 2.60 0.10 0.03~0.05 5.00 3.50 0.10 0.03~0.05 5.10 3.80 0.25 0.03~0.05 7.40 5.50 0.25 0.03~0.05 10.20 7.50 0.25 0.03~0.05 12.80 9.50 0.25 0.03~0.05 14.00 11.00 0.10 0.03~0.05 14.50 12.00 0.10 0.03~0.05 18.00 13.00 0.25 0.03~0.05 22.00 16.00 0.25 0.03~0.05 25.00 19.00 0.25 0.03~0.05 31.00 23.00 0.25 0.03~0.05 36.00 27.00 0.25 0.03~0.05 43.00 32.00 0.25 0.03~0.05 53.00 39.00 0.25 0.03~0.05 62.00 46.00 0.25 0.03~0.05

-

Tubo termorretrátil de FEP

YOZONE, como um fabricante e fornecedor líder no campo da produção de tubo termorretrátil, sempre fornece tubo termorretrátil de alta qualidade. O tubo termorretrátil é geralmente feito de materiais poliméricos, como a poliolefina, que encolhe em diâmetro quando aquecido e se encaixa firmemente no objeto ao qual é aplicado.

Tubo termo-retrátil FEP são materiais de isolamento de alto desempenho concebidos para uma variedade de aplicações industriais e eléctricas. Conhecidos pela sua excelente resistência química, tolerância a altas temperaturas e propriedades de isolamento elétrico, os tubos termorretrácteis FEP oferecem uma proteção fiável para fios, cabos e outros componentes sensíveis.

Tubo termo-retrátil FEP Caraterísticas principais:

1.Alta resistência ao calor: Tubos FEP podem suportar temperaturas até 200°C (392°F), o que os torna adequados para aplicações a altas temperaturas.

2.Resistência química: Estes tubos são altamente resistentes a ácidos, álcalis e solventes, assegurando a durabilidade em ambientes agressivos.

3.Excelente isolamento elétrico: Os tubos FEP proporcionam um isolamento superior, evitando fugas eléctricas e garantindo um funcionamento seguro.

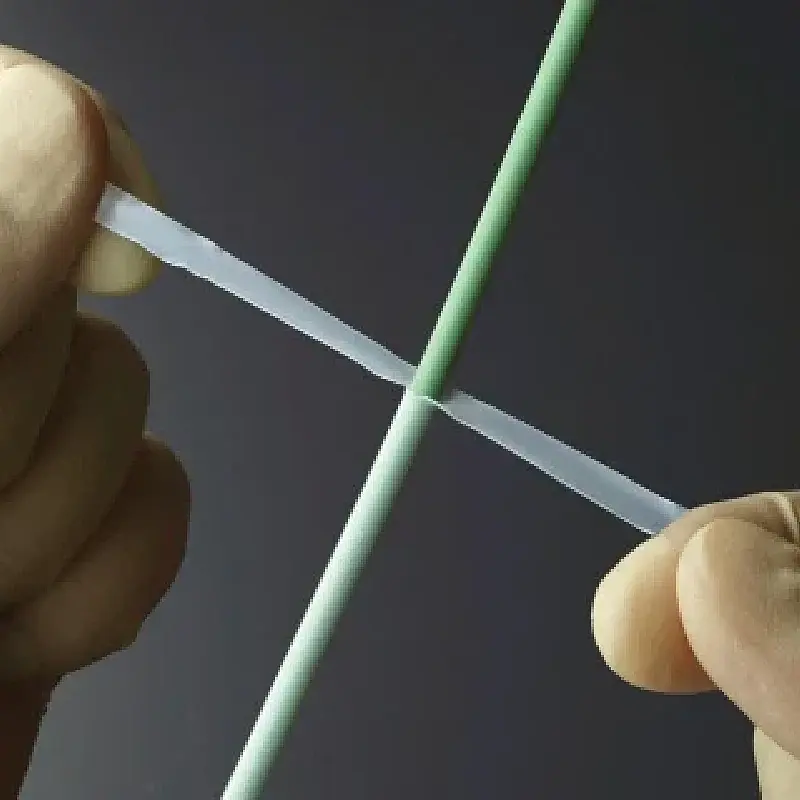

4.Transparência: Os tubos são transparentes, permitindo uma inspeção fácil dos componentes subjacentes.

5.Flexível e duradouro: Os tubos de retração FEP são fáceis de aplicar e mantêm a sua resistência, mesmo em condições extremas.

Caraterística Descrição Componentes principais Polímero de etileno-propileno fluorado (FEP) Gama de resistência à temperatura -200°C a 200°C (-328°F a 392°F) Resistência química Ácidos, álcalis, solventes orgânicos e óleos Vantagens do isolamento elétrico Elevada resistência dieléctrica, estabilidade térmica, resistência química, não inflamabilidade Rácio de retração Normalmente 2:1 ou 3:1 Aplicações dos tubos termorretráteis de FEP

Indústria Descrição da aplicação Benefícios Eletrónica Proteção e isolamento de fios e ligações Maior segurança e durabilidade Automóvel Isolamento e agrupamento de cabos em veículos Resistência ao calor e durabilidade química melhoradas Aeroespacial Fornecimento de isolamento para cablagem em sistemas de aeronaves Proteção leve e fiável em condições extremas Telecomunicações Conectores de isolamento e agrupamento de cabos em equipamentos de telecomunicações Garante a integridade do sinal e a proteção ambiental Dispositivos médicos Proteção de cablagens sensíveis em instrumentos médicos Elevada fiabilidade e conformidade com as normas de higiene Equipamento industrial Isolamento de cabos e proteção de componentes em máquinas Maior resistência aos produtos químicos e ao desgaste mecânico Energias renováveis Isolamento de cablagem em painéis solares e turbinas eólicas Proteção duradoura contra factores ambientais Qual é o tempo de vida dos tubos termorretráteis de FEP?

Os tubos termorretrácteis FEP são conhecidos pela sua longa vida útil e durabilidade. Em condições normais, fornecedores de tubos termorretrácteis podem durar até mais de 20 anos. O seu tempo de vida é largamente determinado por factores ambientais, tais como flutuações de temperatura, exposição à luz UV e contacto com produtos químicos. Em ambientes de elevada tensão, como a exposição contínua a altas temperaturas ou a exposição extrema a produtos químicos, o tempo de vida pode ser mais curto, mas, em geral, os tubos termorretrácteis FEP são altamente resistentes à degradação, o que os torna uma solução fiável a longo prazo.

Qual é a velocidade de encolhimento dos tubos termorretráteis de FEP?

A velocidade de contração do FEP tubos termorretrácteis é relativamente rápido em comparação com outros materiais.

Velocidade de encolhimento dos tubos termorretráteis de FEP

Caraterística

Descrição

Velocidade de contração

Começa a encolher em segundos após a exposição ao calor

Tempo de retração total

Normalmente, demora 1-2 minutos a concluir

Temperatura de retração ideal

200°C a 250°C (392°F a 482°F)

Fonte de calor recomendada

Pistola de calor ou forno

-

FEP100% Tubo transparente flexível virgem Fabricante OEM

Tubo retrátil Fep Descrição do produto

Os tubos FEP da Yozonetech estão em conformidade com as normas médicas e industriais, e também com os certificados de biocompatibilidade.

O diâmetro interno do tubo FEP varia de 0,2 mm a 150 mm, dando assim origem a fios e cabos feitos de FEP.

Propriedades físicas e químicas dos tubos FEP e principais caraterísticas :

Os tubos FEP da Yozonetech cumprem as normas médicas e industriais, incluindo certificados de biocompatibilidade. Com diâmetros internos que variam de 0,2 mm a 150 mm, estes tubos de plástico extrudido deram origem a fios e cabos à base de FEP.

Propriedades físicas e químicas dos tubos FEP e principais caraterísticas:

- Flexibilidade: Tubagem FEP oferece uma maior flexibilidade em relação ao PTFE, alargando as suas aplicações.

- Resistência aos raios UV: Os tubos FEP resistem ao envelhecimento por UV, mantendo as suas propriedades apesar da exposição prolongada aos UV.

- Transparência: A elevada transparência da tubagem FEP ajuda à observação de fluidos.

- Inércia química: Os tubos FEP são excecionalmente resistentes a produtos químicos e corrosivos.

- Propriedades dieléctricas: A baixa constante dieléctrica da tubagem FEP é adequada para aplicações electrónicas.

- Baixo atrito: O coeficiente de fricção muito baixo da tubagem FEP reduz a resistência ao fluxo de fluido.

- Temperatura de fusão: A temperatura de fusão mais baixa dos tubos FEP ajuda no fabrico.

- Antiaderente: A tubagem FEP minimiza a aderência do material com propriedades anti-aderentes.

- Faixa de temperatura: Os tubos FEP funcionam entre -200°C e +205°C.

- Não higroscópico: A taxa de absorção de água dos tubos FEP é <0,01%.

- Aprovado pela FDA: Os tubos FEP têm a aprovação da FDA para contacto com alimentos e muito mais.

Estes atributos fazem com que os tubos FEP sejam a primeira escolha em sectores como a química, a medicina e a eletrónica, oferecendo soluções fiáveis para diversas necessidades.

Os tubos FEP encontram aplicações em:

- Indústria química: Para transferência de líquidos corrosivos e revestimento de vasos de reação.

- Dispositivos médicos: Favorecido para a transferência de líquidos e dispositivos biomédicos devido à sua transparência e resistência química.

- Processamento de alimentos: Utilizado em aplicações de elevada segurança alimentar, como condutas de transporte de alimentos.

- Setor da eletrónica: Com propriedades de isolamento elétrico, tubos de plástico extrudido é amplamente utilizado no isolamento de fios e cabos, no encapsulamento de componentes electrónicos e muito mais.

Comparação com PTFE e PVC:

- Comparada com PTFE: A tubagem FEP oferece maior transparência do que a PTFE, adequada para aplicações monitorizadas visualmente. O PTFE é excelente a temperaturas extremamente elevadas, mas é menos transparente.

- Em comparação com o PVC: os tubos FEP superam o PVC em termos de resistência química e estabilidade a altas temperaturas, sendo adequados para ambientes exigentes. O PVC é mais fácil de fabricar com custos mais baixos, mas é menos eficaz em meios corrosivos e de alta temperatura.

Em resumo, os atributos únicos das tubagens FEP beneficiam significativamente diversos sectores e são comparados com o PTFE e o PVC em contextos específicos.

[embed]https://youtu.be/L2O2-gid8bc[/embed]

[embed]https://youtu.be/Vz5y22nFZ6I[/embed]

[embed]https://youtu.be/wSMQesXHQKs[/embed]

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn