Cómo elegir el tubo termorretráctil FEP adecuado: Parámetros de ingeniería que realmente importan

28 de noviembre de 2025

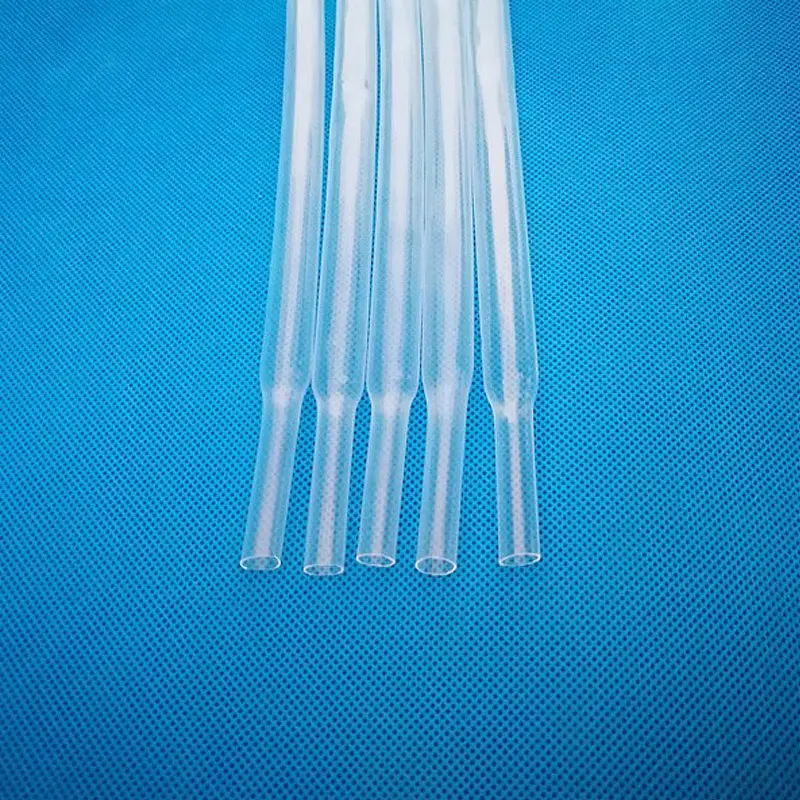

FEP tubo termorretráctil is widely used in semiconductor equipment, medical devices, analytical instruments, automotive sensors, and high-purity fluid handling systems. Yet many engineers and procurement teams struggle to choose the correct tubing specifications because the shrink behavior, tolerance, and thermal stability of FEP differ greatly from other fluoropolymers.

Selecting the wrong shrink ratio or wall thickness often leads to excessive stress on components, uneven encapsulation, or dimensional non-compliance—problems which can be avoided through a structured engineering approach. This guide breaks down the core parameters that determine real-world performance and reliability, supported with quantitative data and selection tables frequently used in Yozonetech’s manufacturing projects.

1. Shrink Ratio: The Foundation of Fit & Reliability

Commercial Tubo termorretráctil FEP typically comes in 1.3:1, 1.6:1, and 2:1 shrink ratios, but choosing the wrong category can create major problems such as excessive residual stress, cracking, or loose fit.

Shrink Ratio Selection Table

| Component Ø(mm) | Recommended FEP Shrink | Notas |

| 0.5-2.0 | 1.6:1 | Balanced shrink forcecommon in sensors & wires |

| 2.0-6.0 | 1.3:1/1.6:1 | Choose 1.3:1 for fragilecomponents |

| 6.0-20 | 2:01 | Needed for complexgeometries |

| >20 mm | A medida | Yozonetech supports large-diameter fabrication |

Higher ratios generate higher shrink force, which is ideal for rugged parts but risky for delicate components such as capillary tubes or microfluidic chips.

2. Wall Thickness and Post-Shrink Dimensions

Wall thickness determines insulation strength, abrasion resistance, and heat dissipation. FEP behaves predictably, but post-shrink thickness is not linearly proportional to the pre-shrink value.

Typical Post-Shrink Wall Thickness Changes

| Espesor de precontracción | Media tras la contracción | Tasa de reducción |

| 0,20 mm | 0,16 mm | -20% |

| 0,30 mm | 0,26 mm | -13% |

| 0,50 mm | 0,44 mm | -12% |

Yozonetech applies precision thermal profiling to keep post-shrink tolerance within ±8%, which is critical for semiconductor and medical applications.

3. Thermal Behavior: Heating Profile Determines Quality

FEP shrinks between 110-200°C, reaching full recovery near 260°C.

A controlled temperature ramp prevents bubbles, whitening (stress), and dimensional distortion.

Standard Shrink Profile Used in Cleanroom Production

| Escenario | Temperatura | Duración | Propósito |

| Precalentar | 110-150°C | 20-40 segundos | Elimina la humedad y reduce el choque térmico |

| Retracción controlada | 180-210°C | 30-80 segundos | Recuperación uniforme |

| Estabilización | 230-260°C | 10-20 segundos | Máxima claridad y alineación molecular |

4. Purity & Surface Quality

High-end industries now require:

- <10 ppm extractables

- ISO Class 5–7 cleanroom packaging

- Surface roughness Ra < 0.3 μm

- No visible gels, fish-eyes, or surface inclusions

Yozonetech maintains these standards through resin filtration, precision extrusion, and multi-stage inspection.

5. Mechanical and Electrical Performance

Below is a condensed data table engineers use during specification:

FEP Mechanical & Electrical Properties

| Parámetro | Valor típico | Por qué es importante |

| Resistencia a la tracción | 20-29 MPa | Withstand mechanica!stress during shrink &operation |

| Alargamiento | 260-320% | Garantiza la flexibilidad en curvas muy cerradas |

| Rigidez dieléctrica | 16-22 kV/mm | Evita averías eléctricas |

| Temperatura máxima de uso continuo | 200°C | Entornos de alta temperatura |

Conclusión

Choosing the correct high temperature heat shrink tubing requires balancing shrink ratio, heating behavior, wall thickness, purity, and performance requirements. When supported by precise manufacturing—such as Yozonetech’s ±8% dimensional tolerance control and cleanroom packaging—the result is long-term reliability in demanding industrial environments.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn