Termorretráctil de pared simple frente a pared doble: Principales diferencias y usos

17 de marzo de 2025

Cómo elegir el termorretráctil adecuado: Cobertura y protección

¿Desea decidir entre tubos termorretráctiles de pared simple o doble? La elección correcta depende del nivel de protección que necesite. Comprender sus diferencias le garantiza el mejor rendimiento para su proyecto. Analicémoslas.

Características compartidas

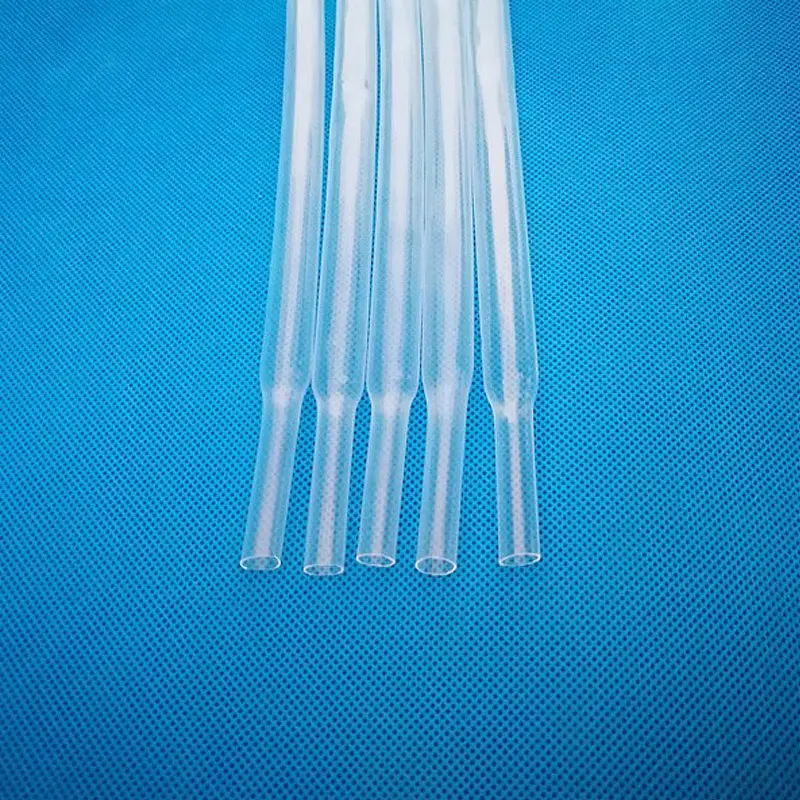

Tanto los termorretráctiles de pared simple como los de pared doble cumplen la misma función principal: aislar, sellar y proteger hilos, cables y otros componentes eléctricos. Estos tubos se contraen cuando se exponen al calor, creando una capa hermética y segura alrededor de la superficie aplicada. El resultado es un acabado liso, duradero y profesional.

Los tubos termorretráctiles se utilizan mucho en todos los sectores y aplicaciones de bricolaje por su asequibilidad, facilidad de instalación y versatilidad. Ya seas electricista, aficionado o simplemente estés arreglando un cable deshilachado en casa, el termorretráctil es una herramienta esencial para una protección duradera.

Comprender las diferencias

Construcción de muros: Qué's en las capas?

Una "pared" en los tubos termorretráctiles es la capa de material que proporciona aislamiento y blindaje. El tipo y el número de paredes influyen en el rendimiento, la protección y la durabilidad.

Termorretráctil de pared simple: Compuesto por una sola capa de polímero retráctil, ofrece aislamiento básico y alivio de tensión.

Termorretráctil de doble pared: Incorpora una capa interior adicional de adhesivo (cola termofusible) que se activa durante el retractilado, creando un sellado impermeable y más resistente.

Al igual que las paredes de una casa protegen contra los elementos externos, las paredes termorretráctiles salvaguardan las conexiones eléctricas de la humedad, la abrasión y los esfuerzos mecánicos. Más paredes equivalen a más protección.

Puntos fuertes y aplicaciones

Termorretráctil de pared simple

Ventajas:

Rápido y fácil de usar

Ligero y flexible

Disponible en varios colores para codificar y organizar

Opciones en negro resistente a los rayos UV para una mayor durabilidad en exteriores

Lo mejor para:

Aislamiento básico y alivio de tensión

Proyectos de cableado de uso general

Identificación por colores de los cables

Entornos de baja exposición con humedad y desgaste mínimos

Termorretráctil de doble pared (Forrado con adhesivo)

Ventajas:

Protección más resistente y duradera

Impide la entrada de humedad, suciedad y contaminantes

Proporciona un refuerzo mecánico adicional

Ideal para temperaturas extremas y condiciones duras

Lo mejor para:

Impermeabilización y sellado ambiental

Aplicaciones exteriores y subterráneas

Cableado de automoción y náutica

Uso industrial y pesado

Elegir el grosor adecuado

Los tubos termorretráctiles están disponibles en distintos grosores de pared, cada uno de ellos diseñado para distintos niveles de protección.

Opciones de pared simple:

Ultrafino - Volumen mínimo, ideal para aplicaciones ligeras.

Delgado - Aislamiento e identificación de uso general.

Medio - Mayor durabilidad para aplicaciones de esfuerzo moderado.

Opciones de doble pared:

Delgado - Capa adhesiva ligera para una impermeabilización sencilla.

Medio - Protección equilibrada contra la humedad y el desgaste mecánico.

Pesado - Máxima resistencia y estanqueidad para condiciones extremas.

Cómo elegir

Para el uso diario y la protección general, los tubos de pared simple son una opción rápida y eficaz. Si su proyecto implica humedad, vibraciones o condiciones extremas, el termorretráctil de doble pared ofrece la seguridad mejorada que necesita.

Reflexiones finales

Los tubos termorretráctiles son una forma sencilla pero eficaz de proteger las conexiones eléctricas. Los de pared simple son ligeros, flexibles y coloridos, mientras que los de pared doble ofrecen mayor durabilidad e impermeabilidad. Elija sabiamente en función de su entorno y sus necesidades de protección, porque cuando se trata de termorretracción, la pared adecuada marca la diferencia.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn