pvdf tubing chemical resistance

-

PVDF-Schrumpfschlauch OEM-Hersteller

PVDF heat shrink tubing Product Specifications:

Herkunftsort: China

Markenname: Yozonetech

Type: Insulator

Material:PVDF

Application:High Temperature

Rated Voltage:1kv

Tensile Strength:30MPA min

Product name:PVDF heat shrink tubing Kynar heat shrink tubes

Tensile strength:30 Mpa min

Operating temperature:-55 ~+150 °C

Elongation at break:150% min

Elongation at break after aging:100% min

Flammability:Flamable

shrink ratio:2:1

Supply Ability:10000 Meter/Meters per Day

Polyvinylidene Fluoride (PVDF) is a thin-wall heat shrinkable tube made from radiation-modified polyvinylidene fluoride. It is transparent, flame retardant, resistant to high temperatures, most oils, and chemicals, as well as being durable and cut-resistant. It is widely used for protecting welding points, terminals, and connecting cables that are exposed to high temperatures, industrial fuels, solvents, and chemical agents.

PVDF heat shrink tubing Product Features:

Shrink Ratio: 2:1

Minimum Shrink Temperature: ≥+135℃

Operating Temperature: -55℃ to +150℃

Flexible, corrosion-resistant, abrasion-resistant, and cut-resistant Environmental Standard: RoHS

Standard Colors: Transparent, Black.

Leistung Leistung Index Prüfverfahren Physical Performance Größe Kundenspezifisch ASTM D 2671 Longitudinal Length Change -10%~+5% ASTM D 2671 Zugfestigkeit ≥24.1 MPa ASTM D 2671 Elongation at Break ≥300% ASTM D 2671 Schrumpfungsverhältnis ≤40% AMS-DTL-23053 Tangent Modulus ≥172 MPa ASTM D 2671 Dichte ≤1.9 g/cm3 ASTM D 2671 Low-Temperature Flexibility No Cracks AMS-DTL-23053(-55℃×4h) Thermal Shock No Dripping, No Flowing, No Cracks ASTM D 2671(250℃×4h) Tensile Strength after Heat Aging ≥19.1 MPa ASTM D 2671(225℃×168h) Elongation at Break after Heat Aging ≥200% ASTM D 2671(225℃×168h) Transparency StabilityIdentification Markings Still Clear AMS-DTL-23053(200℃×24h) Elektrische Isolationsleistung Dielektrische Festigkeit ≥15.7kV/mm ASTM D 2671 Volume Resistivity ≥1012Ω ·cm ASTM D 2671 Chemical Performance Copper Corrosion No Corrosion ASTM D 2671(160℃×16h) Flame Retardant Self-extinguishing within 60s, Paper Flag Burning Degree UL224 VW-1,

ASTM D 2671 C法Water Absorption ≤0.5% ISO 846 B法, 23℃×24h Tensile Strength after Fungus Resistance ≥24.1 MPa ASTM D 2671 Elongation at Break after Fungus Resistance ≥300% ASTM D 2671 Dielectric Strength after Fungus Resistance ≥15.7kV/mm ASTM D 2671 Tensile Strength after Chemical Resistance ≥13.8 MPa ASTM D 2671 Elongation at Break after Chemical Resistance ≥200% ASTM D 2671 Dielectric Strength after Chemical Resistance ≥15.7kV/mm ASTM D 2671

Größe Product ID (mm) Size after shrinking (mm) Shape Package m/roll Inch mm ID Wandstärke 1/32 Φ0.8 ≥0.8 ≤0.5 0.30±0. 10 Rund 200 3/64 Φ1.2 ≥ 1.2 ≤0.6 0.33±0. 10 Rund 200 1/ 16 Φ1.6 ≥ 1.6 ≤0.8 0.33±0. 10 Rund 200 3/32 Φ2.4 ≥2.4 ≤ 1.2 0.33±0. 10 Rund 200 1/8 Φ3.2 ≥3.2 ≤ 1.6 0.35±0. 10 Rund 100 3/ 16 Φ4.8 ≥4.8 ≤2.4 0.35±0. 10 Rund 100 1/4 Φ6.4 ≥6.4 ≤3.2 0.35±0. 10 Flat 100 3/8 Φ9.5 ≥9.5 ≤4.8 0.38±0. 10 Flat 50 1/2 Φ12.7 ≥ 12.7 ≤6.4 0.38±0. 10 Flat 50 5/8 Φ15.0 ≥ 15.0 ≤7.5 0.40±0. 10 Flat 50 3/4 Φ19. 1 ≥ 19. 1 ≤9.5 0.42±0. 10 Flat 50 1 Φ25.4 ≥25.4 ≤ 12.7 0.42±0. 10 Flat 50 1- 1/2 Φ38. 1 ≥38. 1 ≤ 19. 1 0.48±0. 10 Flat 50

175ºC PVDF heat shrink tube

Product Introduction: The 175℃ Polyvinylidene Fluoride Schrumpfschläuche is made from radiation-modified polyvinylidene fluoride, offering transparency, flame retardancy, high-temperature resistance, resistance to most oils and chemicals, as well as durability and cut-resistant properties. Kundenspezifische Schrumpfschläuche finds extensive applications in protecting welding points, terminals, and connecting cables that Hersteller von Schrumpfschläuchen are exposed to high temperatures, industrial fuels, solvents, and chemical agents.

PVDF heat shrink tubing Product Features:

Shrink Ratio: 2:1 Minimum Shrink

Temperature: ≥+175℃

Operating Temperature: -55℃ to +175℃

Flexible, corrosion-resistant, abrasion-resistant, and cut-resistant

Environmental Standard: RoHS

Standard Colors: Transparent, Black.

Leistung Performance Index Prüfverfahren Dichte 1.78 g/cm³ ASTM D791 Zugfestigkeit ≥30 MPa ASTM D2671 Elongation at Break ≥ 150% ASTM D2671 Elongation at Break after Aging ≥ 100% 250C×168h Volume Resistivity ≥ 1014 Ω•cm IEC 60093 Flame Retardant VW- 1 UL224 Cold Bend Flexibility No cracks -55C×4h Thermal Shock No cracks 250C×4h Copper Corrosion No corrosion 180C×168h Copper Stabilization Copper Stabilization 180C×168h

Größe Product size (mm) Size after shrinking (mm) Shape Package m/roll Inch mm ID Wandstärke 3/64 Φ1.2 ≥ 1.2 ≤ 0.6 0.33±0. 10 Rund 200 1/ 16 Φ1.6 ≥ 1.6 ≤ 0.8 0.33±0. 10 Rund 200 3/32 Φ2.4 ≥ 2.4 ≤ 1.2 0.33±0. 10 Rund 200 1/8 Φ3.2 ≥ 3.2 ≤ 1.6 0.35±0. 10 Rund 100 3/ 16 Φ4.8 ≥ 4.8 ≤ 2.4 0.35±0. 10 Rund 100 1/4 Φ6.4 ≥ 6.4 ≤ 3.2 0.35±0. 10 Flat 100 3/8 Φ9.5 ≥ 9.5 ≤ 4.8 0.38±0. 10 Flat 50 1/2 Φ12.7 ≥ 12.7 ≤ 6.4 0.38±0. 10 Flat 50 5/8 Φ15.0 ≥ 15.0 ≤ 7.5 0.40±0. 10 Flat 50 3/4 Φ19.1 ≥ 19.1 ≤ 9.5 0.42±0. 10 Flat 50 1 Φ25.4 ≥ 25.4 ≤ 12.7 0.42±0. 10 Flat 50 1- 1/2 Φ38.1 ≥ 38.1 ≤ 19.1 0.48±0. 10 Flat 50 -

PVDF Large Diameter Customized Tubing OEM Manufacturer

PVDF Tubing Product Description:

1. We use PVDF tubing (polyvinylidene fluoride) as an ideal material for transporting ultra-pure fluids in the pharmaceutical and semiconductor industries because of its inherent high purity, smooth inner surface and extremely low fluid permeability through its walls.

2. PVDF tube is widely used in pure water system and urban water treatment, which also benefits from its advantages of resistance to strong disinfection solutions and no additives or harmful metal ion "extractables".

3. Sometimes engineering applications require Fluorkunststoffschlauch with excellent chemical resistance, high purity and very good mechanical properties, so engineers designed PVDF. PVDF plays a very important role in chemical lining or protective barrier applications

4. PVDF is superior to other fluoropolymers in terms of creep resistance.

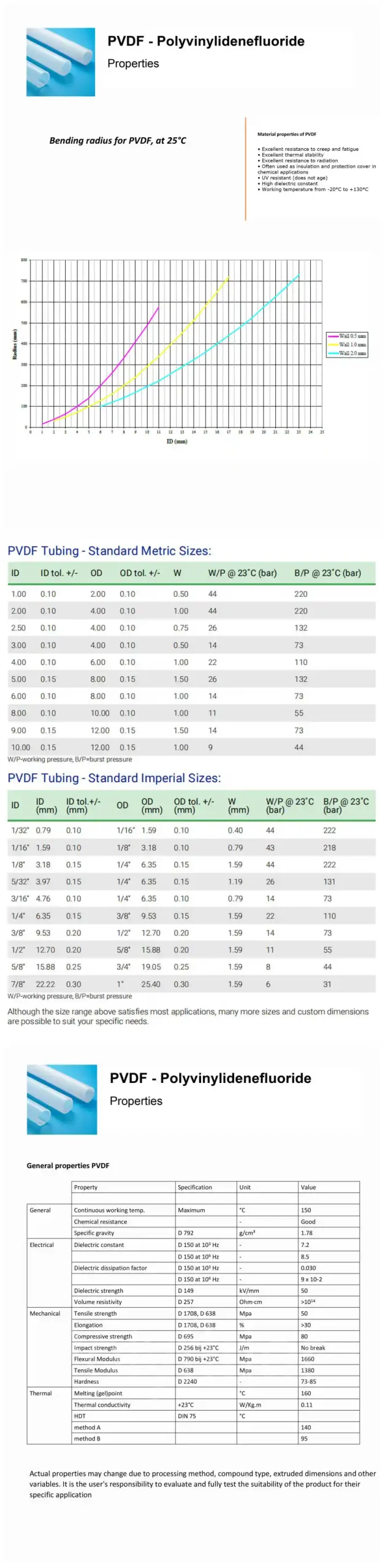

PVDF Tubing Material Properties

• High dielectric constant

• Excellent thermal stability

• UV resistant (does not age)

• Excellent resistance to radiation

• Excellent resistance to creep and fatigue

• Working temperature from -20°C to +130°C

• Often used as insulation and protection cover in chemical applications

PVDF Tubing Produkt-Spezifikation:

Herkunftsort: China

Markenname: YOZONE

Material Marke: Daikin chemical, DuPont. Dongyue & Chenguang (Inland)

Länge: Kundenspezifisch

Die Form: Rund

Color: Black, customized.

Working temperature: -20°C - +130°C

Toleranz: ±0,05 mm

Chemische Beständigkeit: stabil in den meisten Medien.

Elektrische Eigenschaft: Isolationsbeständig

Zertifizierung: UL, CE, FDA, RoHS, REACH.

Norm: ISO9001:2008.

Prüfung: SGS bestanden

Muster: Kostenlos

Bezahlung: T/T

Extrudiertes Rohr Nutzungsdauer: Abhängig von der Umgebung, bitte konsultieren Sie unsere Ingenieure.

Extrudiertes Kunststoffrohr Anwendung: Erdöltransport, Lebensmittelverarbeitung, Elektrotechnik usw.

PVDF Tubing Lieferfähigkeit:

100000 Meter/Meters per Month PVDF Tube

PVDF Tubing Vorlaufzeit:

Menge (Kilogramm) 1 - 10 11 - 50 51 - 100 >100 Geschätzte Zeit(Tage) 3 5 7 Noch zu verhandeln

PVDF Tubing Verpackung und Lieferung

PVDF Tube into Carton and Wooden Pallet

Hafen: Tianjin, Shanghai, Shenzhen, Qingdao.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn