FEP vs. PTFE vs. PFA-Schrumpfschläuche: Ein datengestützter Vergleich für kritische Anwendungen

November 27, 2025

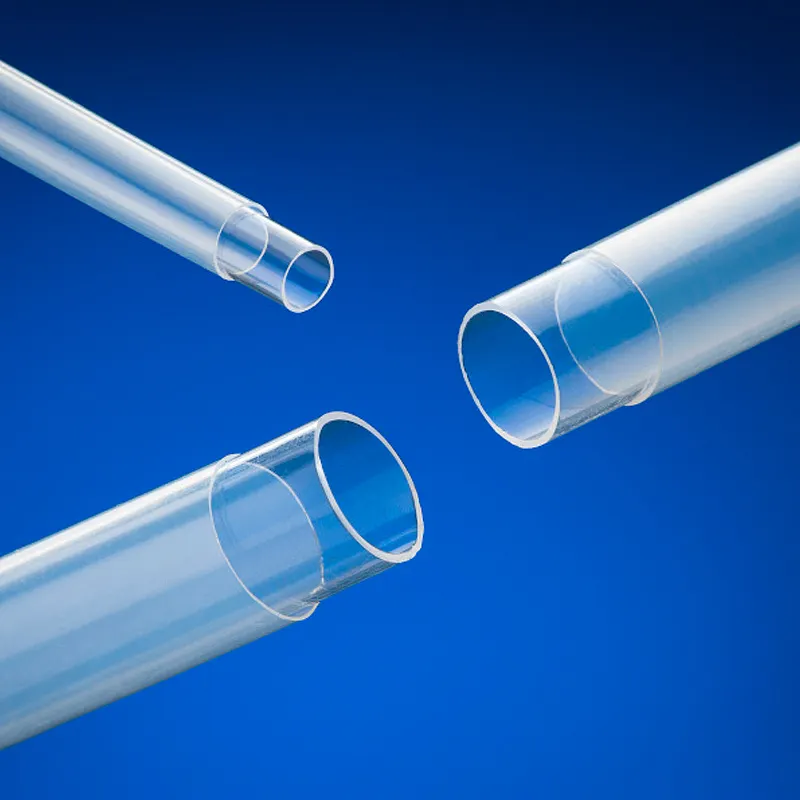

Fluorpolymer Schrumpfschlauch ist für den Schutz von Komponenten in Hochleistungsumgebungen unerlässlich. Unter den verfügbaren Materialien - FEP, PTFE und PFA - bietet jedes einzigartige thermische, chemische und mechanische Eigenschaften. Die Wahl zwischen ihnen kann jedoch ohne klare technische Daten schwierig sein.

Dieser Artikel bietet einen technischen Vergleich auf der Grundlage von Schrumpfbarkeit, dielektrischem Verhalten, Reinheit, mechanischer Festigkeit und Anwendungseignung. Die Daten spiegeln die Prüfmethoden und Fertigungsstandards wider, die in der Reinraumproduktion von Yozonetech für Kunden aus der Halbleiter- und Medizintechnik verwendet werden.

1. Schrumpfbarkeit & Verarbeitungstemperatur

FEP schrumpft leicht; PTFE und PFA benötigen weit höhere Temperaturen.

Vergleich der Schrumpftemperaturen

| Dicke der Vorschrumpfung | Durchschnitt nach der Schrumpfung | Ermäßigungssatz |

| 0,20 mm | 0,16 mm | -20% |

| 0,30 mm | 0,26 mm | -13% |

| 0,50 mm | 0,44 mm | -12% |

FEP ist ideal, wenn Sie Folgendes benötigen geringer Temperaturschock. PTFE/PFA werden bevorzugt für Ultrahochtemperatursysteme.

2. Reinheit und chemische Beständigkeit

Alle drei Materialien bieten eine ausgezeichnete chemische Beständigkeit, aber PFA-Schläuche und FEP werden für Halbleiterausrüstungen bevorzugt, da sie extrahierbare Stoffe und ionische Verunreinigungen aufnehmen können.

Vergleichstabelle zur Reinheit

| Bühne | Temperatur | Dauer | Zweck |

| Vorheizen | 110-150°C | 20-40 Sekunden | Entfernen Sie Feuchtigkeit und reduzieren Sie Wärmeschocks |

| Kontrolliertes Schrumpfen | 180-210°C | 30-80 Sekunden | Einheitliche Verwertung |

| Stabilisierung | 230-260°C | 10-20 Sekunden | Maximale Klarheit und molekulare Ausrichtung |

Yozonetech verwendet Harzfiltration und Verpackungen der Klasse 7, um die Anforderungen von Halbleiter-OEMs zu erfüllen.

3. Mechanische Festigkeit

PTFE ist das stärkste, FEP das flexibelste.

Mechanische Eigenschaften

| Parameter | Typischer Wert | Warum es wichtig ist |

| Zugfestigkeit | 20-29 MPa | Widersteht mechanischer Beanspruchung beim Schrumpfen und im Betrieb |

| Dehnung | 260-320% | Sorgt für Flexibilität bei überscharfen Biegungen |

| Dielektrische Festigkeit | 16-22 kV/mm | Verhindert elektrische Ausfälle |

| Maximale Dauergebrauchstemperatur | 200°C | Umgebungen mit hohen Temperaturen |

Dies wirkt sich auf die Handhabung beim Schrumpfen und die langfristige Haltbarkeit aus.

4. Dielektrische Leistung

| Material | Dielektrische Festigkeit | Dielektrizitätskonstante | Anmerkungen |

| FEP | 16-22 kV/mm | 2.1 | Ausgezeichnete Konsistenz |

| PFA | 15-20 kV/mm | 2.1 | Geringfügig höhere Abweichung |

| PTFE | 18-25 kV/mm | 2 | Beste Hochtemperaturstabilität |

Alle drei sind starke Isolatoren; FEP-Rohre sind am stabilsten bei Feuchtigkeit und chemischen Veränderungen.

5. Zusammenfassung der Eignung für die Anwendung

Wo jedes Material am besten funktioniert

| Art der Anwendung | FEP | PFA | PTFE |

| Halbleiter WetProcess | √ | √ Am besten | - |

| Hochtemperatur-Verdrahtung | √ Am besten | √ | √ Am besten |

| Medizinische SchläucheEinkapselung | √ | √ | - |

| chemische Übertragungssysteme | √ | √ Am besten | √ |

| Einsturzsensoren | √ Beste (Flexibilität) | √ | - |

Schlussfolgerung

FEP, PTFE und PFA bieten jeweils unterschiedliche Vorteile.

- FEP: Bestes Gleichgewicht zwischen Flexibilität, Reinheit und einfacher Schrumpfung

- PFA: Am besten geeignet für ultrareine und Hochtemperatur-Halbleitersysteme

- PTFE: Am besten geeignet für extreme thermische Umgebungen

Die Kenntnis dieser Unterschiede ermöglicht es Ingenieuren und Beschaffungsteams, Materialien auf der Grundlage von Leistung, Kosten und Verarbeitungsbedingungen auszuwählen. Yozonetech unterstützt alle drei Lösungen und liefert Schrumpfschläuche in Reinraumqualität mit strengen Abmessungs- und Reinheitskontrollen.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn