5 Ultimative Lösungen: Was verwenden Klempner im Jahr 2025 anstelle von PTFE?

August 28, 2025

Abstrakt

Polytetrafluoroethylene (PTFE) tape has long been a standard material for sealing threaded pipe joints in a vast array of plumbing applications. Its low-friction surface and chemical inertness make it a convenient and generally effective solution. However, its limitations, including a propensity for shredding, specific temperature and pressure constraints, and potential for improper application, have necessitated the development and continued use of alternative sealing methods. This examination explores the primary materials and compounds that serve as substitutes for PTFE tape. The analysis delves into traditional options like pipe dope (thread sealant compound) and the age-old technique of hemp and paste. It further investigates modern chemical solutions such as anaerobic resin compounds, which offer high-strength, vibration-resistant seals for demanding industrial contexts. Finally, it considers the role of advanced fluoropolymers like Perfluoroalkoxy (PFA) and Fluorinated Ethylene Propylene (FEP), which represent an evolution beyond PTFE for creating entire fluid handling systems, and clarifies the specific, non-pressurized applications for silicone sealants and gaskets. The objective is to provide a nuanced understanding of each alternative’s mechanism, ideal use cases, and comparative advantages, empowering professionals and enthusiasts to select the most appropriate sealing technology for any given plumbing challenge.

Wichtigste Erkenntnisse

- Pipe dope provides a robust, lubricating seal that actively fills thread gaps.

- Anaerobic sealants create a hard, vibration-proof plastic lock for metal threads.

- Hemp and paste offer a reliable, traditional seal, especially for coarse threads.

- Advanced fluoropolymers like PFA and FEP offer superior thermal and chemical performance.

- Understanding what do plumbers use instead of PTFE ensures a durable, leak-free joint.

- Silicone is best for flexible, non-pressurized seals like drains, not threaded pipes.

- The right choice depends on pressure, temperature, materials, and application needs.

Inhaltsübersicht

- Understanding the Standard: The Role of PTFE Tape in Plumbing

- Solution 1: Pipe Dope (Thread Sealant Compound) – The Classic Alternative

- Solution 2: Anaerobic Resin Compounds – The Chemical Solution

- Solution 3: Hemp and Paste – The Time-Tested Traditional Method

- Solution 4: Advanced Fluoropolymers (PFA & FEP) – The Industrial Upgrade

- Solution 5: Silicone Sealants & Gaskets – The Flexible Option

Understanding the Standard: The Role of PTFE Tape in Plumbing

Before we can meaningfully explore the alternatives, we must first develop a deep appreciation for the thing we are seeking to replace. PTFE tape, often known by the DuPont brand name Teflon, is so ubiquitous on job sites and in home toolkits that its function is often taken for granted. We wrap it around a thread, tighten the fitting, and expect it to prevent leaks. But what is actually happening in that moment of connection? How does this simple white tape accomplish its task, and what are its inherent fragilities that lead us to ask, what do plumbers use instead of PTFE?

What is PTFE and Why Is It So Common?

Polytetrafluoroethylene, or PTFE, is a synthetic fluoropolymer of tetrafluoroethylene. Its discovery was, like many scientific breakthroughs, a happy accident. In 1938, a chemist at DuPont was working with refrigerant gases and found that a pressurized bottle that should have been full was empty, yet weighed the same as when it was full. Upon cutting it open, he discovered a waxy, incredibly slippery white powder. That powder was PTFE. Its properties were extraordinary. It was almost completely inert, meaning it wouldn’t react with acids, bases, or solvents. It had one of the lowest coefficients of friction of any known solid, making it incredibly slippery. It was also hydrophobic, repelling water with vigor.

In the context of plumbing, these properties are harnessed in the form of a thin, unsintered tape. It is vital to understand that PTFE tape is not an adhesive. It does not glue the threads together. Its primary role is twofold: it acts as a lubricant and a void filler.

Imagine looking at the threads of a pipe and a fitting under a microscope. They may look perfectly sharp to the naked eye, but at a microscopic level, they are a landscape of peaks and valleys. When you screw a male fitting into a female fitting, these imperfect surfaces meet. Without any sealant, tiny helical gaps remain between the crests and roots of the threads—perfect pathways for water or gas to escape under pressure.

When you wrap PTFE tape around the male threads and tighten the joint, the soft tape is forced into these microscopic valleys. It deforms and compresses, filling the voids and creating a physical barrier that is impermeable to the fluid within the pipe. Simultaneously, the incredibly low friction of the PTFE lubricates the threads. This allows you to tighten the fitting further than you could with dry threads, achieving a greater degree of mechanical compression and a tighter, more secure joint. It makes both assembly and, just as importantly, future disassembly, a much smoother process.

The Limitations of PTFE Tape: Why Seek Alternatives?

If PTFE tape works so well, why would we ever need an alternative? The answer lies in the nuances of different applications and the material’s own inherent weaknesses. A solution that is perfect for a bathroom sink faucet might be a catastrophic failure in a high-pressure hydraulic line or a chemical processing plant.

One of the most common frustrations is shredding. As you tighten a fitting, particularly if the threads are sharp or if the fitting is readjusted, the tape can tear. Small shreds of PTFE can break off and be carried downstream by the fluid flow. In a simple faucet, this might result in a clogged aerator—an annoyance, but easily fixed. In a more complex system, however, these shreds can clog delicate solenoid valves, pressure regulators, or sensitive instrumentation, leading to system malfunction or failure.

Application error is also rampant. The tape must be wrapped in the correct direction—the same direction the fitting will be tightened. If wrapped backward, the act of tightening the fitting will unravel the tape, rendering it useless. Using too little tape will fail to fill the voids, while using too much can prevent the threads from engaging properly, potentially even cracking the female fitting from the excessive pressure.

Furthermore, standard PTFE tape has its limits regarding temperature and pressure. While it performs well in typical residential hot and cold water systems, it can degrade, creep, or fail in high-temperature steam lines or high-pressure hydraulic systems. While different densities and grades of PTFE tape exist (e.g., pink for water lines, yellow for gas lines), they all share a common polymer backbone with fundamental limitations. This is a point where one must consider if a more robust sealing method is necessary, or if the system itself requires components made from superior materials, like those from a specialized pipe manufacturing expert. The cost of PTFE, while low per roll, can become a factor in industrial settings where labor costs for re-doing failed joints or the cost of downtime outweigh the initial material savings. These limitations force us to broaden our perspective and consider the full spectrum of sealing technologies available.

Solution 1: Pipe Dope (Thread Sealant Compound) – The Classic Alternative

Long before PTFE tape became the go-to, plumbers relied on a different substance to ensure leak-free joints: pipe dope. This term, which sounds more like a relic from a bygone era, refers to a wide category of paste-like thread sealant compounds. It remains a trusted and often preferred method for many professional plumbers today, representing a fundamentally different approach to sealing threads. It is a primary answer to the question of what do plumbers use instead of PTFE.

The Anatomy of Pipe Dope

Pipe dope is a non-hardening or semi-hardening paste, typically applied with a small brush attached to the container’s lid. Its composition is a carefully formulated blend of ingredients designed to perform several functions at once. At its core, it consists of a base liquid—often a mixture of oils, resins, and solvents—that carries solid filler particles.

These fillers are the key to its sealing action. They can include a variety of materials, such as clay, graphite, talc, or even microscopic particles of PTFE itself. When you brush the dope onto the male threads of a pipe and tighten the fitting, the liquid base lubricates the connection, much like PTFE tape does. But as the joint is tightened, the solid fillers are physically forced into the gaps and imperfections between the threads.

Unlike tape, which is a passive filler, the paste actively flows and packs into every crevice. The liquid carrier ensures a complete and uniform distribution of these sealing particles. The result is a dense, impenetrable plug that blocks any potential leak path. Most modern pipe dopes are “soft-setting,” meaning they don’t fully harden or cure. They remain a viscous, putty-like consistency within the joint. This is a deliberate design feature. It allows for slight adjustments during installation and, critically, makes future disassembly possible without requiring extreme force or heat.

Application and Best Practices

Using pipe dope effectively requires a slightly different technique than using tape, but it is straightforward.

- Preparation is Key: As with any sealing method, the threads on both the male and female fittings must be clean and free of dirt, oil, or old sealant. A wire brush is your best friend here.

- Apply to Male Threads Only: This is a cardinal rule. Using the applicator brush, apply a liberal but even coat of dope to the male threads. Why only the male threads? If you apply it to the female threads, as you screw the pipe in, the leading edge of the male thread will act like a plow, scraping the dope and pushing a glob of it into the pipe system. This can cause blockages just as easily as shredded PTFE tape. By applying it to the male threads, the excess is pushed outward, where it can be easily wiped away.

- Ensure Full Coverage: Make sure to work the compound into the root of the threads all the way around the pipe. Don’t just paint the tips. The goal is to fill the entire threaded void.

- Assemble and Tighten: Screw the fittings together by hand, then use wrenches to tighten to the appropriate torque. You will see a small bead of excess sealant squeeze out of the joint. This is a good sign; it indicates that the joint is full. Wipe away the excess for a clean finish.

The beauty of soft-setting dope is its forgiveness. It lubricates the joint, protects the threads from corrosion and galling (a form of wear caused by adhesion between sliding surfaces), and creates a positive seal that can withstand significant pressure and vibration.

Pipe Dope vs. PTFE Tape: A Comparative Analysis

To truly understand when to choose one over the other, a direct comparison is helpful. Both are excellent tools when used correctly, but they have distinct personalities.

| Merkmal | Pipe Dope (Thread Sealant Compound) | PTFE Tape |

|---|---|---|

| Sealing Mechanism | Active sealant and lubricant; fills voids with paste and solid fillers. | Passive filler and lubricant; a physical barrier that deforms into voids. |

| Ease of Application | Can be messy; requires a brush and wiping excess. | Generally clean if applied correctly. |

| Skill Required | Low; forgiving application. Just “paint” it on. | Moderate; must be wrapped in the correct direction with proper tension. |

| Risk of Contamination | Low if applied to male threads only. Excess is pushed out. | Moderate; risk of shredding and sending particles downstream. |

| Sealing Ability | Excellent; actively fills all gaps for a very robust seal. | Good, but can fail if threads are damaged or tape is applied poorly. |

| Adjustability | Allows for minor adjustments after initial tightening. | Cannot be backed off or adjusted without compromising the seal. |

| Disassembly | Easy; the compound lubricates and prevents corrosion. | Easy, but tape can sometimes bind or shred upon removal. |

| Chemical/Temp Rating | Varies by specific formula; wide range of specialized products available. | Varies by tape density/grade, but generally more limited than specialized dopes. |

For many plumbers, pipe dope is the preferred method for critical connections, especially on gas lines (using a gas-rated formula) or on older, slightly imperfect threads where the active filling capability of the paste provides a more reliable seal.

Solution 2: Anaerobic Resin Compounds – The Chemical Solution

If pipe dope is the classic, reliable workhorse, then anaerobic resin compounds are the high-performance, specialized tool for when the stakes are highest. This category of sealant operates on a fascinating chemical principle that makes it uniquely suited for high-pressure, high-vibration, and high-temperature environments. When a plumber reaches for an anaerobic sealant, it’s because the joint cannot be allowed to fail. It is a definitive, modern answer to the query of what do plumbers use instead of PTFE.

The Science of Anaerobic Sealants

The word “anaerobic” literally means “living without air.” This is the secret to how these sealants work. In the bottle, the sealant is a stable, liquid resin. It remains liquid as long as it is exposed to oxygen in the air. However, when you apply this liquid to the threads of a metal pipe and screw it into a fitting, you radically change its environment. You confine it to a thin film between the metal threads, starving it of oxygen.

This absence of air, combined with the presence of metal ions from the pipe threads, acts as a catalyst. It triggers a chemical polymerization reaction. The liquid resin begins to cure, transforming into a hard, tough, thermoset plastic. It’s a bit like a magic trick: a liquid that solidifies simply by being hidden from view. This cured plastic locks the threads together, filling 100% of the space between them and creating a perfect, monolithic seal. It doesn’t just block leak paths; it makes the threaded connection a single, solid unit.

Advantages in High-Stress Environments

The properties of the cured anaerobic resin are what make it so valuable in demanding industrial and commercial applications.

- Vibration Resistance: In systems with pumps, motors, or significant fluid turbulence, vibration can cause standard threaded fittings to slowly back off over time, leading to leaks. Because the anaerobic sealant cures into a solid plastic that locks the threads, it makes the joint virtually immune to loosening from vibration.

- High-Pressure Sealing: The cured plastic can withstand immense pressures, often exceeding the burst pressure of the pipe or fitting itself. There are no voids, no tape to extrude, and no paste to be pushed out.

- Temperature and Chemical Resistance: Different formulations are available that are engineered to resist a wide range of chemicals, solvents, and extreme temperatures, far surpassing the capabilities of basic PTFE tape or general-purpose pipe dope.

- Controlled Strength: These sealants are available in various strengths. Low-strength formulations allow for disassembly with standard hand tools. Medium-strength (the most common) may require a bit more force. High-strength formulations create a nearly permanent bond that often requires heating the joint with a torch to over 200°C (400°F) to soften the plastic before it can be disassembled with large wrenches. This “permanence” is a feature, not a flaw, in applications where the joint should never come apart.

These attributes make anaerobic sealants the standard choice for hydraulic systems, fuel and gas lines, refrigerant lines, and process piping in factories where reliability is paramount.

Considerations for Use

While powerful, anaerobic sealants are not a universal drop-in replacement for tape or dope. Their unique chemistry comes with specific requirements.

- Material Compatibility: The standard curing mechanism relies on the presence of metal ions. They work best on “active” metals like brass, copper, and iron. For “inactive” metals like stainless steel, anodized aluminum, or for plastic-to-plastic or plastic-to-metal threads, the reaction can be very slow or may not happen at all. In these cases, a special chemical primer must be applied to the threads first to initiate the curing process.

- Cure Time: Unlike the instant seal provided by tape or dope, anaerobic sealants require time to cure. Fixture time (when the joint can be handled and is sealed against low pressure) might be 15-30 minutes, while a full cure (to achieve maximum pressure and solvent resistance) can take up to 24 hours, depending on the temperature, the type of metal, and the size of the gap between threads. The system cannot be fully pressurized until this cure time has elapsed.

- Gap Filling: While they fill gaps perfectly, they have limits. They are designed for the tight tolerances of modern threaded fittings. They are generally not suitable for very loose, damaged, or coarse threads, where the gap might be too large for the resin to cure properly.

Choosing an anaerobic sealant is a deliberate engineering decision. It represents a trade-off: you gain unparalleled strength and reliability in exchange for a longer installation time and potentially more difficult disassembly.

Solution 3: Hemp and Paste – The Time-Tested Traditional Method

In our modern world of advanced polymers and chemical engineering, it can be easy to dismiss older methods as obsolete. Yet, in the craft of plumbing, some traditional techniques persist not out of nostalgia, but because they offer a unique combination of effectiveness and reliability that modern materials sometimes struggle to replicate. The use of hemp fibers and pipe jointing paste is one such method. It is a journey back to the roots of the trade, offering a tactile and robust solution that has sealed pipes for centuries.

A Nod to Plumbing Heritage

Before plastic tapes and chemical resins, plumbers had to rely on natural, readily available materials. Hemp, a fiber derived from the Cannabis sativa plant, proved to be an ideal candidate. The long, strong fibers could be spun and wrapped around pipe threads to act as a physical packing material. When combined with a paste, typically based on linseed oil and other fillers, it created an exceptionally durable seal.

The mechanism is beautifully simple and effective. The plumber wraps a specific quantity of hemp fibers into the threads of the male pipe end, following the direction of tightening. Then, a layer of paste is liberally applied over the hemp. As the fitting is screwed on, several things happen. The paste acts as a lubricant, just like its modern counterparts. The hemp fibers are compressed, physically filling the large voids in the threads. But the real magic happens once the system is filled with water. The natural hemp fibers absorb a small amount of water and swell slightly. This swelling action causes the hemp packing to expand, tightening itself within the joint and compensating for any minor imperfections or future settling. It creates a living, active seal that can actually improve over time.

When is Hemp and Paste Still the Right Choice?

While you are unlikely to see a plumber using hemp and paste to install a new kitchen faucet in a modern American home, this method remains highly relevant and is even standard practice in many parts of Europe, particularly for central heating and water systems. Its persistence is due to a few key advantages, especially in specific situations.

- Coarse and Imperfect Threads: This is where hemp and paste truly shine. Older buildings, large-diameter iron pipes, or fittings with less-than-perfect thread quality present a challenge for thin PTFE tape or even pipe dope. The thick body of hemp fibers can easily fill large, irregular gaps where tape would shred or dope would be insufficient.

- Adjustability: One of the most significant advantages of a hemp and paste joint is the ability to “back off” or adjust the fitting slightly (e.g., up to a quarter turn) after it has been tightened, without causing a leak. The pliable mass of hemp and paste will accommodate this small movement. Attempting to back off a joint sealed with PTFE tape is a guaranteed leak, as it breaks the seal. Anaerobic sealants, once cured, cannot be adjusted at all. This adjustability is invaluable when trying to align valves or taps perfectly.

- Durability: A properly made hemp and paste joint is incredibly robust and long-lasting. The combination of the physically packed fibers and the water-swelling effect creates a seal that is highly resistant to vibration and pressure changes. Many plumbers who work on old steam heating systems swear by it as the only method that reliably holds up over decades.

A Dying Art or a Relevant Skill?

Learning to use hemp and paste is more of a craft than simply applying a product. It requires a feel for how much hemp to use—too little will not seal, too much will prevent the joint from assembling. The fibers must be combed and wrapped neatly. It is a skill honed through practice.

While its use has declined in new residential construction in some regions, understanding and being able to execute a hemp and paste joint is a mark of a truly experienced and versatile plumber. It represents a connection to the history of the trade and a practical tool for dealing with the real-world challenges of maintaining and repairing older plumbing systems. Furthermore, the materials are natural and biodegradable, a point of increasing relevance in an environmentally conscious world. It is not merely an old way of doing things; it is a different way, with a distinct set of strengths that ensure its place in the modern plumber’s arsenal.

Solution 4: Advanced Fluoropolymers (PFA & FEP) – The Industrial Upgrade

When we ask “what do plumbers use instead of PTFE,” the conversation often stays focused on sealing threads. But in high-stakes industrial environments like semiconductor fabrication, chemical processing, or pharmaceutical manufacturing, the question expands. It’s not just about sealing a single joint; it’s about the integrity of the entire fluid transport system. Here, the limitations of standard PTFE drive a move toward its more advanced chemical cousins: PFA and FEP. These materials represent a significant leap in performance and processability.

Moving Beyond Basic PTFE

PFA (Perfluoroalkoxy) and FEP (Fluorinated Ethylene Propylene) are both fluoropolymers, part of the same family as PTFE. You can think of them as refined successors, designed to retain the remarkable properties of PTFE while overcoming its single biggest drawback: its inability to be melt-processed.

PTFE has an extremely high melting viscosity, meaning even when heated past its melting point, it doesn’t flow like a typical plastic. It maintains a gel-like consistency. This is why it cannot be injection molded or extruded using conventional techniques. PTFE parts are typically made by compressing powder and then sintering (heating) it, a process that limits the complexity of the shapes that can be produced.

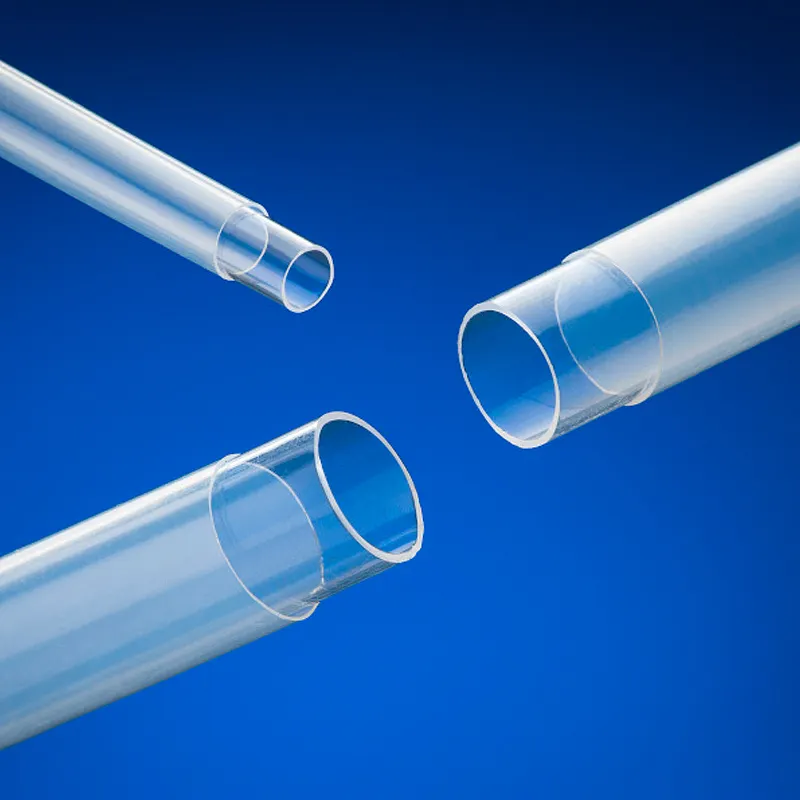

PFA and FEP, on the other hand, were engineered to have a lower melting viscosity. This fundamental difference is a game-changer. It means they can be processed using conventional thermoplastic techniques like extrusion and injection molding. This allows for the creation of complex, seamless components like valve bodies, custom fittings, pump impellers, and crucially, smooth, clear, continuous tubing. These high-performance Polytetrafluorethylen-Schläuche and their PFA/FEP counterparts form the backbone of modern high-purity industries.

To better grasp the distinctions, consider the following comparison:

| Eigentum | PTFE (Polytetrafluorethylen) | FEP (Fluoriertes Ethylen-Propylen) | PFA (Perfluoralkoxy) |

|---|---|---|---|

| Max Service Temperature | ~260°C (500°F) | ~204°C (400°F) | ~260°C (500°F) |

| Verarbeitbarkeit der Schmelze | No (cannot be injection molded) | Yes (excellent melt flow) | Yes (good melt flow) |

| Chemische Beständigkeit | Ausgezeichnet | Ausgezeichnet | Excellent (often considered the best) |

| Flexibilität | Stiff; prone to creep (cold flow) | Very flexible; excellent flex life | More flexible than PTFE, less than FEP |

| Optische Klarheit | Opaque (white) | Optically clear | Translucent |

| Kosten | Baseline | Höher als PTFE | Highest of the three |

The Superiority of PFA and FEP in Demanding Applications

The ability to melt-process these materials opens up a world of possibilities.

- Purity and Seamless Construction: In a semiconductor fab, where a single microscopic particle can ruin a multi-million dollar batch of microchips, fluid pathways must be perfectly smooth and free of any crevices where contaminants could hide. Because PFA and FEP can be extruded into seamless tubing and molded into smooth fittings, they create systems with minimal risk of particle generation or entrapment, a stark contrast to the potential for shredding with PTFE tape.

- Enhanced Performance: While FEP has a slightly lower service temperature, PFA matches PTFE’s thermal performance while also offering better flex life and greater resistance to “creep,” the tendency of PTFE to deform under sustained load. PFA is often considered the ultimate material for handling highly aggressive chemicals at elevated temperatures.

- Transparenz: FEP is optically clear. This is a massive advantage in many systems, as it allows for visual confirmation of fluid flow, detection of bubbles or contamination, and observation of processes without needing to break the line.

- Weldability: PFA and FEP components can be heat-welded together, creating a permanent, seamless, and leak-proof bond without the need for any threaded connections or sealants at all. This is the gold standard for high-purity fluid handling.

From Thread Sealant to System Component

In these advanced applications, the focus shifts from sealing a thread to eliminating the thread entirely wherever possible. When a threaded connection is unavoidable, the solution is often not a tape or dope, but a high-integrity compression fitting where a PFA or FEP ferrule is compressed onto a tube, creating a seal against a fitting body.

The conversation moves beyond what plumbers use for a joint and becomes what engineers use to build a system. The choice of PFA or FEP is a decision about the fundamental material of the entire wetted path. It’s about ensuring absolute purity, total chemical compatibility, and long-term reliability in environments where the cost of failure is astronomical. This level of specialization and material science expertise is the domain of dedicated manufacturers who understand the profound differences between these remarkable polymers. It is a testament to the idea that the right solution often involves rethinking the problem from the ground up.

Solution 5: Silicone Sealants & Gaskets – The Flexible Option

In any comprehensive discussion about sealing pipes and fittings, the topic of silicone sealant inevitably arises. It is a common sight in hardware stores and a staple in many toolboxes. However, its role in plumbing is one of the most frequently misunderstood. Using silicone incorrectly can lead to frustrating failures, while using it for its intended purpose provides a flexible, durable seal that other materials cannot match. This is less an alternative to PTFE tape and more of a different tool for a different job, often working in concert with gaskets.

Understanding Silicone’s Role

Let’s be unequivocally clear from the outset: RTV (Room Temperature Vulcanizing) silicone sealant is not a thread sealant for pressurized pipe fittings. You should not use the silicone caulk from your bathroom to seal the threads on a water heater supply line or a compressed air fitting.

Why not? Silicone sealants are elastomeric, meaning they cure into a flexible, rubber-like substance. They are designed to accommodate movement and provide a waterproof barrier. They do not possess the mechanical strength or rigidity to resist the immense forces present in a tapered pipe thread joint under pressure. The pressure would simply extrude the soft silicone out of the threads, resulting in a leak. Furthermore, the lubricating properties of the uncured silicone can lead an installer to over-tighten the fitting, potentially causing the fitting to crack.

So, where does silicone belong in plumbing? Its proper place is in low-pressure or, more commonly, non-pressurized drainage applications. Think about installing a kitchen sink basket strainer. A ring of plumber’s putty or, increasingly, a bead of 100% silicone sealant is applied to the underside of the strainer’s flange before it is set into the sink. As the locknut is tightened from below, the silicone squeezes out to form a perfect, custom-fit, waterproof gasket between the flange and the sink basin. Its job is to prevent water from the sink from leaking out around the drain, not to seal pressurized threads. Other appropriate uses include sealing around the base of a toilet, sealing the joints in a shower surround, or as a flexible seal on some types of drain and vent piping.

Gaskets: The Pre-Formed Seal

Closely related to the idea of a formed-in-place silicone seal is the pre-formed gasket. A gasket is a shaped piece of material, often a type of rubber, neoprene, fiber, or silicone, that is placed between two stationary, flat surfaces (flanges). When these surfaces are bolted together, the gasket is compressed, creating a seal.

This is a fundamentally different sealing principle than that of a tapered pipe thread. A thread sealant works within the helical path of the threads themselves. A gasket works by being squeezed between two faces. You find gaskets everywhere in plumbing:

- In faucet supply lines: The end that connects to the shut-off valve has a rubber cone washer inside that acts as a gasket.

- In toilet supply lines: Similar cone or flat washers seal the connections.

- In drain pipes: The slip-joint washers used to connect P-traps are a form of compression gasket.

- In flanged industrial pipes: Large pipes in industrial settings are often connected with flanges sealed by large, flat gaskets.

The material of the gasket is chosen based on the application: EPDM rubber for water, nitrile rubber (Buna-N) for oils and fuels, and silicone for high temperatures or food-grade applications. For instance, food-grade silicone tubing and gaskets are prized for their flexibility and wide temperature range, though care must be taken as they can age at extremely high temperatures.

The Right Place for Flexibility

The choice between a thread sealant, a silicone bead, or a pre-formed gasket is not a matter of preference; it is dictated by the design of the connection itself. A tapered pipe thread fitting (NPT, BSPT) requires a thread sealant. A flanged or compression fitting requires a gasket. A drain flange requires a surface sealant like silicone or putty.

Using the right sealant in the right place is a hallmark of professional work. Silicone’s value lies in its flexibility, excellent water resistance, and wide temperature range. It allows for thermal expansion and contraction and slight movement between components without breaking its seal. It is a fantastic problem-solver for a specific set of plumbing challenges, but it is not the answer when wondering what do plumbers use instead of PTFE on a pressurized, threaded joint. Recognizing this distinction is key to creating reliable, long-lasting, and leak-free plumbing systems.

Häufig gestellte Fragen (FAQ)

Can I use pipe dope on plastic (PVC, CPVC) threads?

Yes, but it is absolutely vital to use a pipe dope that is specifically formulated and approved for use on plastics. Standard pipe dopes contain solvents that can chemically attack and weaken PVC, CPVC, or ABS plastic, leading to stress cracking and eventual failure of the fitting. Always check the product label for compatibility with the specific type of plastic you are using.

Is pipe dope better than PTFE tape?

Neither is inherently “better”; they are different tools with different strengths. Pipe dope generally creates a more robust seal because it actively fills all voids, and it is more forgiving of imperfect threads. PTFE tape is cleaner to apply and is often sufficient for new, well-machined fittings. Many plumbers prefer dope for critical connections like gas lines (using a gas-rated formula) and tape for standard water connections.

How do I remove cured anaerobic sealant?

The method depends on the strength of the sealant. Low-strength formulations can typically be disassembled with standard hand tools. Medium- and high-strength formulations create a very strong bond. Disassembly usually requires applying localized heat to the fitting with a propane torch or heat gun to approximately 200-250°C (400-480°F). This heat softens the cured plastic, allowing the joint to be broken loose with wrenches.

Is PTFE tape safe for drinking water lines?

Yes, provided you are using the correct type. PTFE tape intended for potable water systems should be certified to NSF/ANSI 61 standards. This ensures that no harmful chemicals will leach from the tape into the drinking water. This is often a white, standard-density tape, but always check the packaging for the proper certification marks.

What is the main difference between PFA and PTFE?

The single most important difference is melt processability. PFA can be melted and processed using conventional injection molding and extrusion, allowing for the creation of complex, seamless parts. PTFE cannot. This makes PFA a far more versatile material for manufacturing components like valve bodies, liners, and transparent tubing. PFA also generally offers slightly better mechanical properties at high temperatures.

Why shouldn’t I use silicone sealant on pressurized pipe threads?

Silicone cures into a soft, flexible rubber. It does not have the mechanical strength to resist the forces within a tapered pipe thread joint under pressure. The water or gas pressure will simply push the soft silicone out of the threads, creating a leak. It is designed for surface sealing and low-pressure applications, not for sealing high-pressure threads.

What do plumbers use instead of PTFE for gas lines?

For natural gas or propane (LPG) lines, plumbers almost exclusively use either a pipe dope or an anaerobic sealant that is specifically rated and listed for use with gas. These products are formulated to resist the hydrocarbons in the gas and to create an absolutely reliable, bubble-tight seal. Yellow-colored PTFE tape is also rated for gas, but many professionals prefer the more positive seal of a paste compound for these critical connections.

How many times should I wrap PTFE tape around a thread?

A general rule of thumb is three to five wraps. The tape should be wrapped tightly in the same direction that the fitting will be tightened. Too few wraps will not adequately fill the thread voids, and too many wraps can prevent the threads from engaging properly and may even put enough stress on the female fitting to cause it to crack.

Schlussfolgerung

The journey through the world of pipe sealing reveals a landscape far more rich and nuanced than a simple roll of white tape might suggest. We began with the standard, PTFE tape, appreciating its convenience but also acknowledging its limitations in terms of shredding, application sensitivity, and performance under stress. This led us to explore what plumbers use instead of PTFE, uncovering a spectrum of solutions tailored to specific challenges.

We rediscovered the enduring wisdom of pipe dope, a classic compound that actively seals and lubricates, offering a forgiving and robust alternative. We ventured into the realm of chemical engineering with anaerobic sealants, understanding how their unique ability to cure in the absence of air provides unparalleled strength and vibration resistance for the most critical industrial applications. We paid respect to the heritage of the craft with hemp and paste, a traditional method whose effectiveness on large or imperfect threads remains relevant today.

Expanding our view, we saw how in high-purity and chemically aggressive environments, the conversation shifts from sealing threads to engineering entire systems with advanced fluoropolymers like PFA and FEP. Finally, we clarified the specific, vital role of silicone and gaskets, recognizing them not as thread sealant substitutes but as essential tools for flexible and flanged connections.

Ultimately, there is no single “best” alternative. The optimal choice is a function of a careful analysis of the application’s demands: the pressure and temperature of the fluid, its chemical nature, the materials of the pipes and fittings, and the need for future disassembly. A true craftsperson or engineer does not have a favorite; they have a deep understanding of their entire toolkit. They know when the simple elegance of tape is sufficient, when the reliable bulk of dope is required, and when the unyielding strength of a chemical bond is the only acceptable answer. This knowledge, combined with a commitment to quality materials sourced from expert suppliers, is the foundation of every durable, reliable, and leak-free connection. The integrity of our complex systems, from the faucet in our homes to the reactors in our factories, depends on it. This deep dive into material science and application is a core value for any serious.

Referenzen

cntopa.com. (2024, August 12). How to install PTFE fittings: Step-by-step guide.

Ideal Bell Pneumatic. (2025, April 3). What is the alternative to PTFE tubing? Ideal-bell.

insulation-tubings.com. (2025, April 15). PTFE tube vs silicone tube: Which one is safer for food-grade transportation?

Kevin. (2024, June 3). PTFE vs PVC: Comparing two essential industrial materials. MachiningPTFE.

Xu, R. (2025, Januar 22). Was sind die Unterschiede zwischen Teflon und PTFE-Rohren? YouFumi.

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn