Wofür werden PTFE-Rohre im 3D-Druck verwendet?

Juli 8, 2025

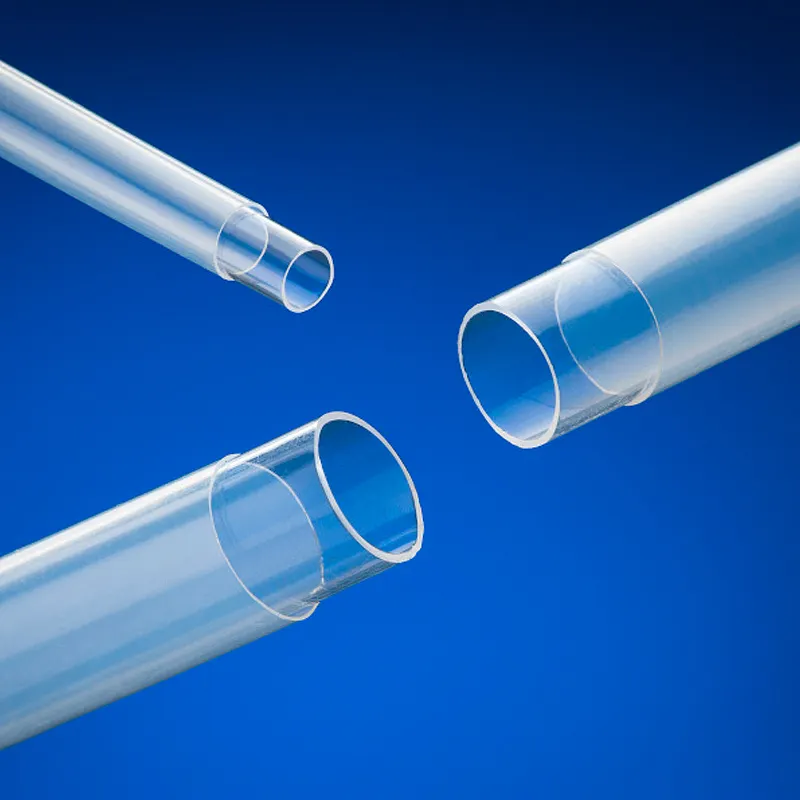

3D printing relies on precise components to ensure smooth operations and high-quality results, and PTFE tubing plays a key role in making this happen. But what exactly does it do in 3D printing? Let’s explore its main uses, dive deeper into technical details, and look at real-world applications to understand why it’s a top choice for printers.

1. Feeding High-Temperature Filaments

In FDM (Fused Deposition Modeling) 3D printers, filaments like PEEK (polyetheretherketone) or PEI (polyetherimide) need to be fed into hot nozzles that reach 300°C or higher. PTFE tubing excels here because it can handle extreme heat, up to 260°C continuously, with short-term tolerance up to 300°C—without melting or warping. Its low friction coefficient (as low as 0.05) ensures filaments glide through smoothly, preventing jams that ruin prints.

Unlike regular plastic tubes (such as PVC or nylon), PTFE tubings don’t soften or stick to the filament, even when heated. This is critical for materials like PEEK, which require consistent feeding pressure to avoid layer shifts in the final print. For example, in aerospace 3D printing facilities, where PEEK is used to make lightweight components, Extrudierte Rohre from reliable manufacturers ensures 99% jam-free printing, reducing waste and downtime.

2. Protecting Wires and Cables

3D printers have complex electrical systems with wires and sensors that control movement (stepper motors) and temperature (thermistors). PTFE tubing acts as a protective sleeve, shielding these components from heat radiating from the nozzle, dust from filament particles, and wear from constant movement. Its excellent electrical insulation (volume resistivity ≥10¹\u2078Ω·cm, per IEC 60243 standards) prevents short circuits, a common issue in printers with exposed wiring.

In industrial printers with enclosed chambers (used for printing high-strength materials), where temperatures can reach 150°C inside, PTFE tubing maintains its insulating properties, ensuring the printer’s electronics function reliably. This durability is why automotive 3D printing labs, which run printers 24/7, rely on it to protect critical wiring.

3. Managing Coolant and Lubricant Flow

Industrial 3D printers, especially those used for metal printing (like selective laser melting machines), generate intense heat during operation. Cooling systems are essential to prevent nozzle overheating and maintain print accuracy. Extruded Tubing made of PTFE carries coolants like deionized water or ethylene glycol through the machine. Its chemical resistance ensures it won’t react with coolants, and its rigidity (yet flexibility) stands up to constant flow and temperature fluctuations.

It also works for lubricant lines, ensuring moving parts like linear rails and lead screws stay well-oiled without contamination. In a case study from a metal 3D printing facility in Germany, switching to PTFE tubing for lubricant delivery reduced maintenance intervals by 40%, as the tubing didn’t degrade or clog with lubricant residue.

4. Handling Chemicals in Resin Printing

Resin 3D printers use liquid photopolymers that cure under UV light, but these resins (and their cleaning solvents like isopropyl alcohol) can corrode standard plastic tubes. PTFE tubing is resistant to almost all chemicals, including these harsh substances. It safely transports resin from reservoirs to the print bed, preventing leaks that waste material and damage the printer.

This chemical resistance also makes cleanup easier: resin won’t stick to the tubing’s non-stick surface, so a quick rinse with solvent keeps it clean. Dental labs, which use resin printers to make custom crowns, appreciate this feature—PTFE tubings reduce the risk of cross-contamination between different resin colors or types.

5. Why Choose Quality PTFE Tubing for 3D Printing?

Not all PTFE tubing is the same. Poorly made tubes can have uneven wall thickness (a result of shoddy extrusion processes) or rough interiors that snag filaments. This is where trusted manufacturers like YOZONE come in.

YOZONE, a leading PTFE tubing supplier, offers high-quality options like extruded and convoluted tubing, all certified by FDA, ISO 9001, and CE. Their Extruded Tubing has precise dimensional tolerances (±0.02mm for wall thickness) and smooth surfaces, ensuring consistent performance in 3D printers. With over 15 years of experience, they understand the needs of 3D printing—whether you need 0.05mm capillary tubes for delicate jewelry printers or braided hoses for industrial models handling high-pressure coolant flow.

Their rigorous testing (including burst pressure tests up to 500 psi and thermal cycling tests from -200°C to 260°C) ensures PTFE tubings that work reliably, print after print.

Final Thoughts

PTFE tubing is an unsung hero in 3D printing, handling heat, chemicals, and friction to keep printers running smoothly. From feeding high-performance filaments to protecting critical electronics, its unique properties make it irreplaceable. When choosing tubing for your 3D printer, opt for quality Extruded Tubing that meets industry standards—your prints (and your printer) will thank you.

If you are looking for high-quality pipes, please kontaktieren Sie uns directly!

+86-13752771911

+86-13752771911 E-mail:ptfetube@yozonetech.cn

E-mail:ptfetube@yozonetech.cn